Drum-shaped toothed rail wheel for coal mining machine and preparing method of drum-shaped toothed rail wheel

A technology of drum-shaped teeth and rack wheels, which is applied in mechanical equipment, belts/chains/gears, earthwork drilling, etc., can solve the problem that tooth surfaces and edges are easy to be contacted and squeezed, shortening the service life of rack wheels, and coal mining To solve the problems such as the increase of the load of the machine walking, to achieve the effect of excellent anti-eccentric load performance, reduce contact stress, and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

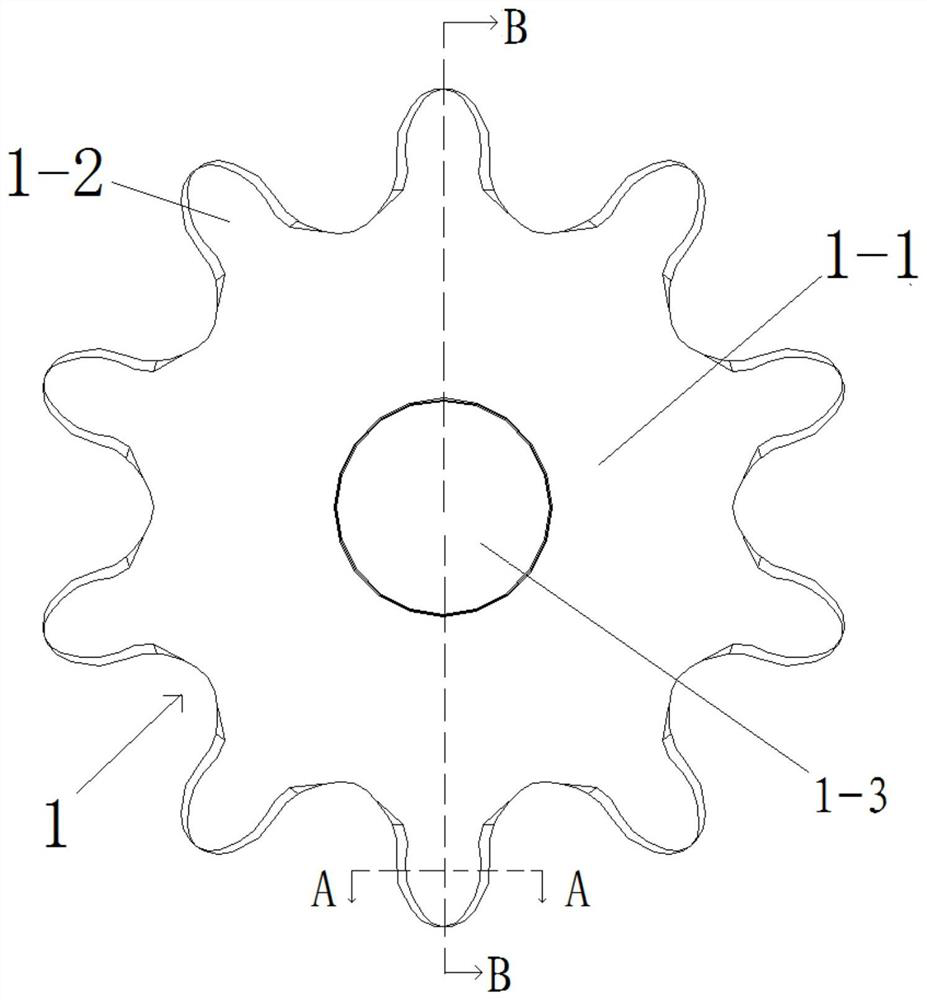

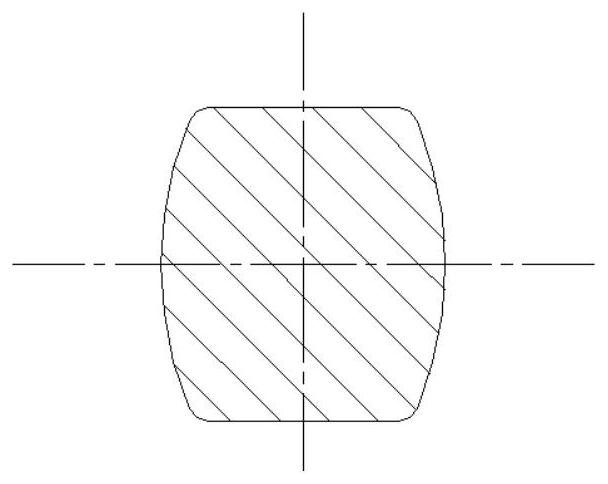

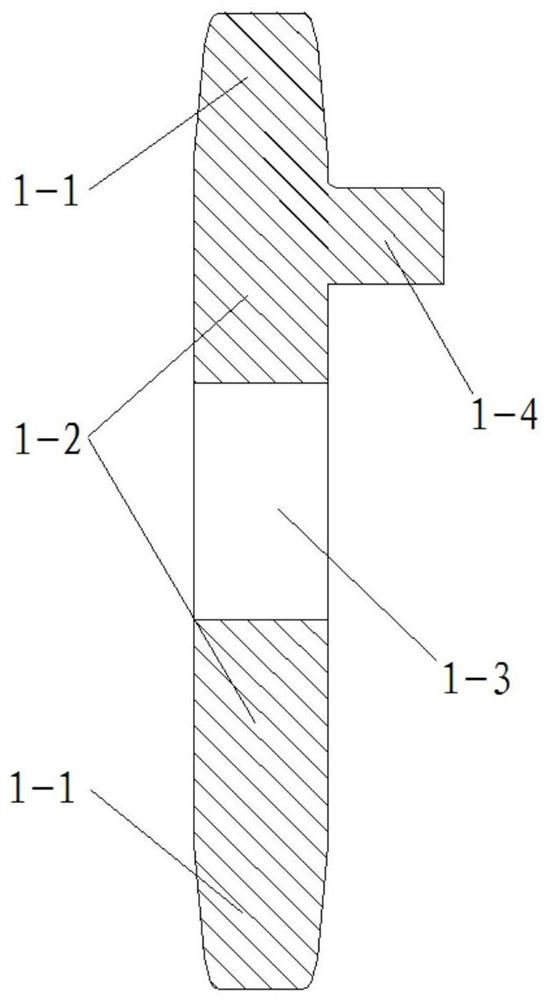

[0043] Such as figure 1 , figure 2 with image 3 As shown, the drum-shaped rack wheel 1 for a coal shearer in this embodiment includes a rack wheel main body 1-1 and a plurality of drum-shaped teeth 1-2 surrounding the outer edge of the rack wheel main body 1-1 , the tooth surface of the drum-shaped tooth 1-2 smoothly transitions to an arc drum-shaped surface from the center line of the tooth surface to both sides, forming a drum-shaped tooth surface. The meshing lines coincide, and the center position of the rack wheel main body 1-1 is provided with a bearing matching through hole 1-3 that is matched with the bearing. The surface of the rack wheel main body 1-1 is along the bearing matching through hole 1-3 3 is surrounded by a plurality of connection keys 1-4.

[0044] Such as Figure 4 with Figure 5 As shown, the use state of the drum rack wheel of the present invention is: the driving gear 2 equipped with the bearing sleeve 3, the bushing 4, the distance sleeve 5, t...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] Step 1. Carry out vacuum smelting of 18Cr2Ni4WA alloy steel, and then carry out secondary refining outside the furnace to obtain the drum-shaped rack wheel precursor;

[0049] Step 2, forging the drum rack wheel precursor obtained in step 1, then normalizing, and then tempering after air cooling, to obtain the drum rack wheel precursor after tempering; the forging The forging ratio is 3.5, the temperature of the normalizing treatment is 960°C, the temperature of the tempering treatment is 640°C, the grain size of the drum rack wheel precursor after the tempering is 7 grades, with Symptomatic tissue is grade 2;

[0050] Step 3: Carrying out contour processing and rough machining of the tooth shape of the drum-shaped rack wheel precursor after tempering obtained in step 2, and then performing aging treatment to obtain the drum-shaped rack wheel blank; the outline The machining and rough machining of the gear tooth p...

Embodiment 3

[0058] This embodiment includes the following steps:

[0059] Step 1. Carry out vacuum smelting of 18Cr2Ni4WA alloy steel, and then carry out secondary refining outside the furnace to obtain the drum-shaped rack wheel precursor;

[0060] Step 2, forging the drum rack wheel precursor obtained in step 1, then normalizing, and then tempering after air cooling, to obtain the drum rack wheel precursor after tempering; the forging The forging ratio is 3.2, the temperature of the normalizing treatment is 940°C, the temperature of the tempering treatment is 650°C, the grain size of the drum rack wheel precursor after the tempering is 7 grades, with Symptomatic tissue is grade 2;

[0061] Step 3: Carrying out contour processing and rough machining of the tooth shape of the drum-shaped rack wheel precursor after tempering obtained in step 2, and then performing aging treatment to obtain the drum-shaped rack wheel blank; the outline The machining and rough machining of the gear tooth p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com