Resource-saving type 290 MPa-grade steel plate for building anti-seismic energy dissipation structure and manufacturing and application of steel plate

A resource-saving and structural technology, applied in the field of metallurgy, can solve the problems of high cost and insufficient use of manganese alloy resources, and achieve the effects of strong laminar tear resistance, economical composition design, and high section shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

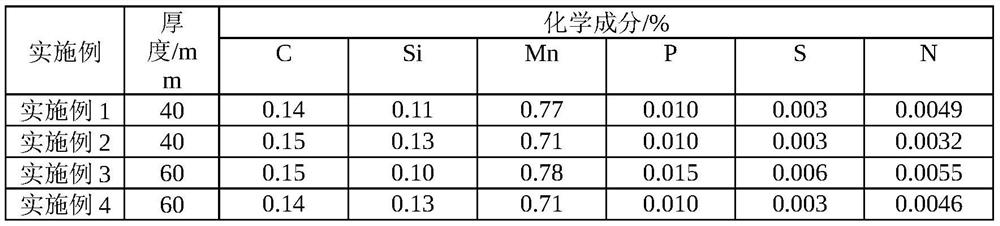

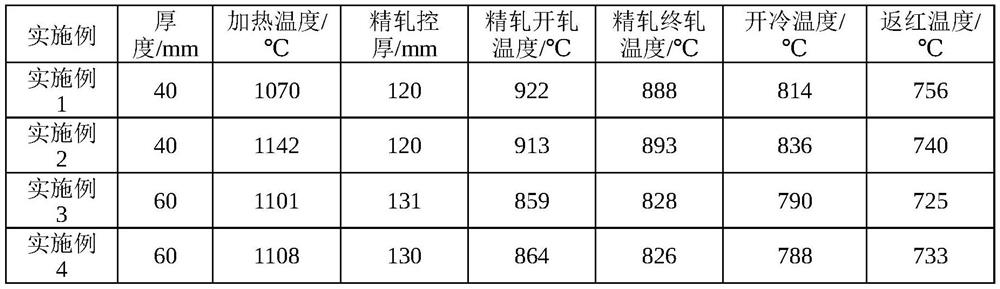

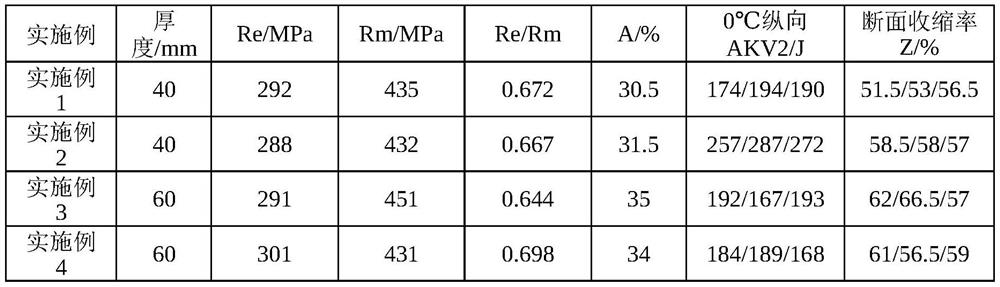

[0059] According to the composition and content of the chemical components shown in Table 1, and the steel plate manufacturing process control conditions shown in Table 2, a 290MPa-level steel plate for building anti-seismic energy-dissipating structures with a thickness of 40mm was manufactured. The specific production process is as follows:

[0060] 1. Desulfurization molten iron: KR desulfurization process is adopted, and the S content of molten iron is 0.030%.

[0061] 2. Converter smelting: adding alloy to dissolve the alloy evenly.

[0062] 3. Out-of-furnace refining (LF+RH): Out-of-furnace refining is carried out through LF furnace and RH vacuum furnace treatment to reduce O, H, N, H and other harmful gases and P, S content, and remove impurities in molten steel.

[0063] 4. Continuous casting of slabs: Protective casting of 300mm thick slabs, equipped with electromagnetic stirring and light pressing.

[0064] 5. Slow cooling of the slab: slow cooling of the slab off t...

Embodiment 2

[0078] According to the composition and content of the chemical components shown in Table 1, and the steel plate manufacturing process control conditions shown in Table 2, a 290MPa-level steel plate for building anti-seismic energy-dissipating structures with a thickness of 40mm was manufactured. The specific production process is as follows:

[0079] 1. Desulfurized hot metal: KR desulfurization process is adopted, and the S content of the hot metal is 0.040%.

[0080] 2. Converter smelting: adding alloy to dissolve the alloy evenly.

[0081] 3. Out-of-furnace refining (LF+RH): Out-of-furnace refining is carried out through LF furnace and RH vacuum furnace treatment to reduce O, H, N, H and other harmful gases and P, S content, and remove impurities in molten steel.

[0082] 4. Continuous casting of slabs: Protective casting of 300mm thick slabs, equipped with electromagnetic stirring and light pressing.

[0083] 5. Slow cooling of the slab: slow cooling of the slab off the ...

Embodiment 3

[0097] According to the composition and content of the chemical components shown in Table 1, and the steel plate manufacturing process control conditions shown in Table 2, a 290MPa-level steel plate for building anti-seismic energy-dissipating structures with a thickness of 60mm was manufactured. The specific production process is as follows:

[0098] 1. Desulfurization molten iron: KR desulfurization process is adopted, and the S content of molten iron is 0.030%.

[0099] 2. Converter smelting: adding alloy to dissolve the alloy evenly.

[0100] 3. Out-of-furnace refining (LF+RH): Out-of-furnace refining is carried out through LF furnace and RH vacuum furnace treatment to reduce O, H, N, H and other harmful gases and P, S content, and remove impurities in molten steel.

[0101] 4. Continuous casting of slabs: Protective casting of 300mm thick slabs, equipped with electromagnetic stirring and light pressing.

[0102] 5. Slow cooling of slabs: slow cooling of slabs off the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com