Technique for producing refined salt from salt production waste liquid

A preparation process and technology for refining salt, applied in the field of salt production, can solve problems such as occupation of land resources, waste of resources, leakage loss, etc., and achieve the effects of protecting the marine environment, reducing losses, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

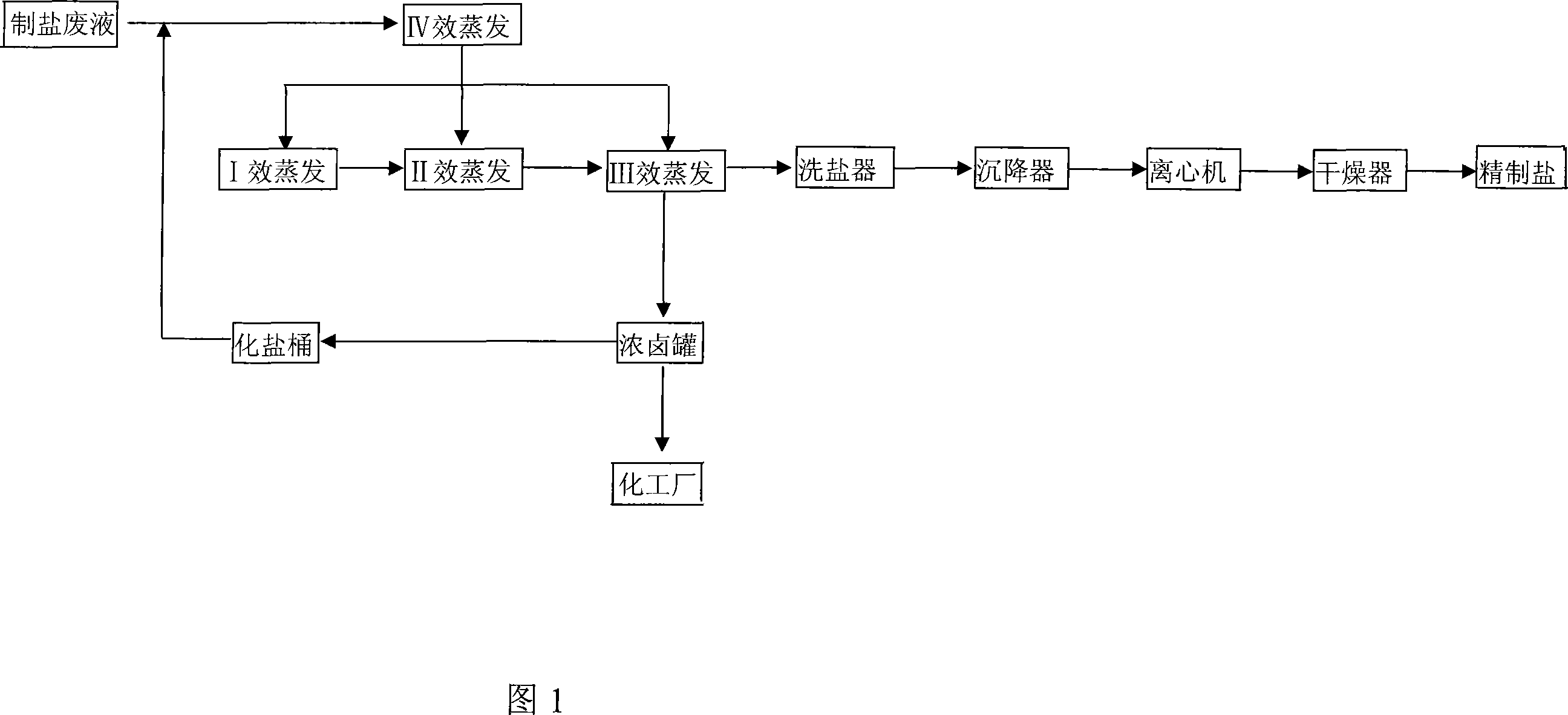

[0013] The implementation process of the preparation process of the present invention for producing refined salt using salt-making waste liquid as raw material is described in conjunction with the accompanying drawings and examples.

[0014] The preparation process of the present invention using salt-making waste liquid as raw material to produce refined salt adopts sea salt salt-making waste liquid directly into the evaporation tank to evaporate salt and co-produce potassium sulfate, magnesium chloride, refined salt and bromine process technology, that is, use salt-making waste The liquid is used as the raw material, and the vacuum evaporation process of the external heating type reverse circulation axial discharge four-effect belt concentrated brine tank is adopted. (The so-called "effect" refers to the efficiency of steam utilization, that is, the evaporation method in which steam is only used once is called single-effect evaporation. If the secondary steam evaporated from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com