Method and device for low temperature carbonization and pyrolysis of low-rank coal and oil shale

A technology of oil shale and low-rank coal, which is applied in the field of large-scale internal heating vertical furnace dry distillation process and use equipment, can solve the problems of increasing cost, restricting the comprehensive utilization of coal tar and gas deep processing, etc., to increase the calorific value and increase the use value , the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

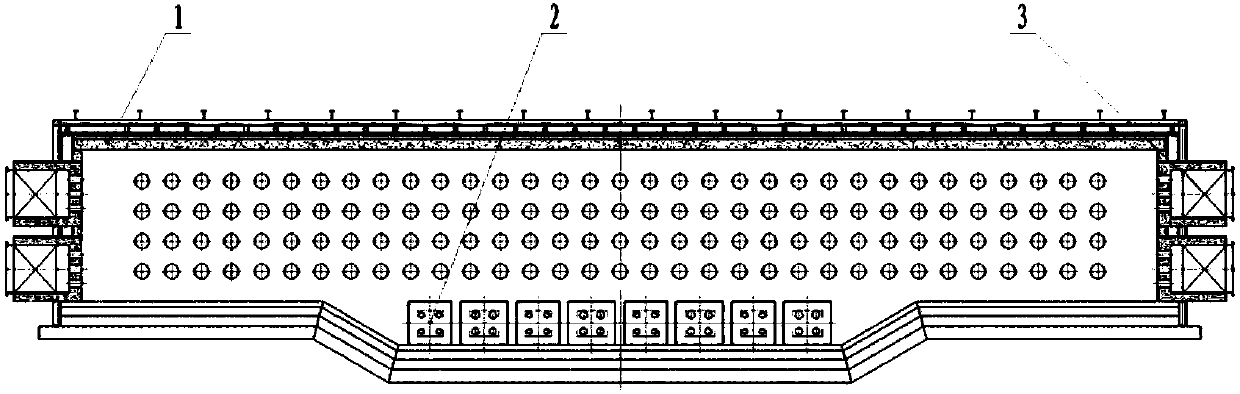

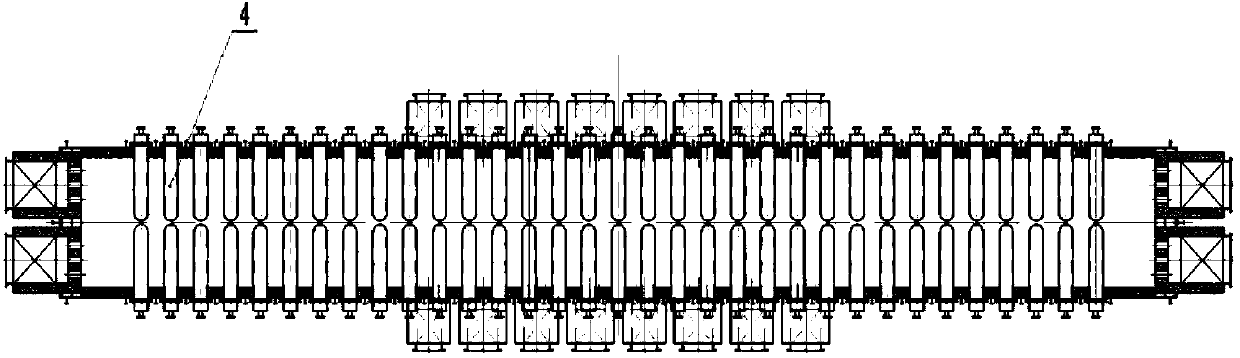

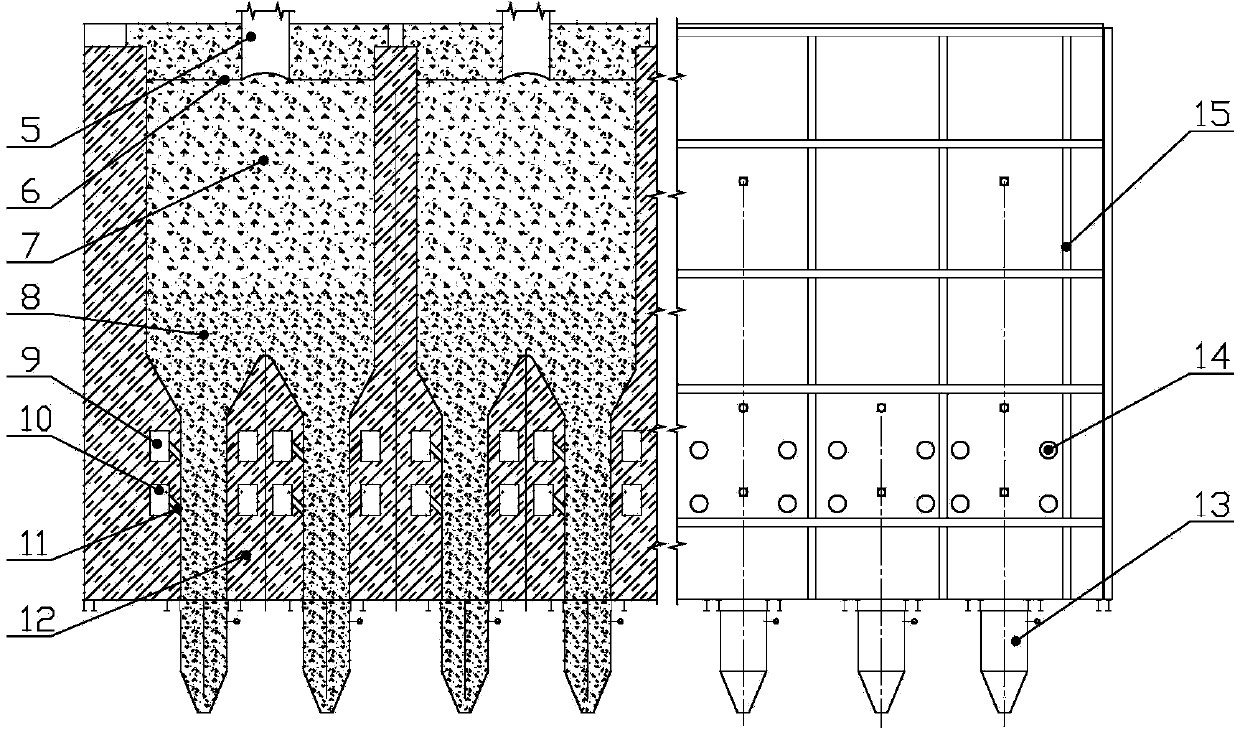

[0029] The gas preheating device includes a regenerative combustion furnace 1, which uses low calorific value gas as fuel to generate high-temperature flue gas at 1000-1300°C. The end and bottom of the regenerative combustion furnace 1 are equipped with double regenerative burners. There are radiant tube preheaters 4 evenly distributed inside; the regenerative combustion furnace 1 provides heat for the gas preheating device, and the radiant tube preheater 4 is the preheating system of the gas preheating device. Due to the adoption of regenerative combustion technology, It can maximize gas utilization and reduce fuel consumption.

[0030] The low calorific value gas sent from the gas purification workshop passes through the bottom double regenerative burner 2 and the end double regenerative burner 3 of the regenerative combustion furnace 1 to burn to produce high temperature flue gas of about 1000-1300 ℃, which will be sent by the gas purification workshop The cold gas sent ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com