Production technology capable of efficiently separating high-activity hirudin based on anion exchange column

An anion exchange column and production process technology, which is applied in the directions of leech inhibitors, peptide preparation methods, protease inhibitors, etc., can solve the problems of unsuitable for industrial production, unsuitable for injection drugs, complicated extraction methods, etc. The effect of convenient use, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

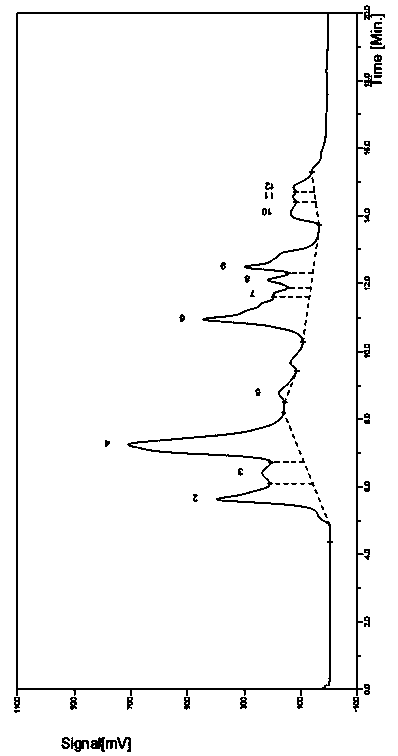

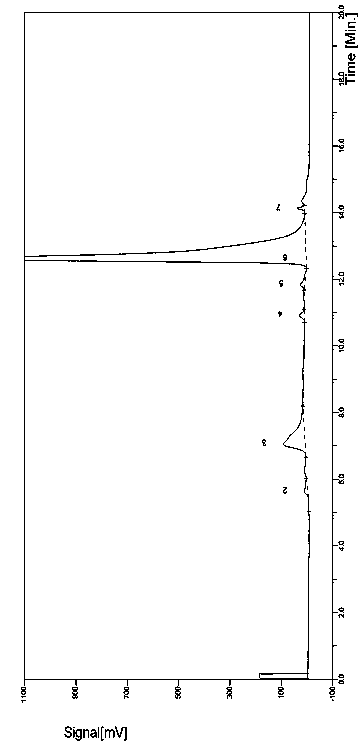

[0052] Weigh 20g of leech powder (activity 300ATU / g) produced by Nanning Jinhai Kekang Pharmaceutical Technology Co., Ltd., add 20ml of ultrapure water, 20ml of 5%TCA (PH 1.15), centrifuge at 8000r / min for 20min, and supernatant for later use ;The precipitation continued to be extracted twice, all the supernatants were mixed, the pH was adjusted to 4.0, and three times of cold acetone was added to precipitate, and the HPLC test results were shown in figure 1 .

[0053] DEAE-silica gel column liquid chromatographic column (20×100mm) for separation and purification, the chromatographic column filler is macroporous silica gel coated with a layer of diethylaminoethyl methacrylate polymer on the surface, the pore diameter of the macroporous silica gel is 300 ?, and the particle size of the filler is is 30 μm.

[0054] The sample solution is detected by liquid chromatography with a UV detector, the detection wavelength is 210nm, the flow rate is 5mL / min, the gradient: 0%B (A: 10mM...

Embodiment 2

[0056] Weigh 20g of leech powder (activity 160ATU / g) produced by Nanning Jinhai Kekang Pharmaceutical Technology Co., Ltd., add 20ml of ultrapure water, 20ml of 5% TCA (PH 1.15), centrifuge at 8000r / min for 15min, and supernatant for later use ;The precipitation continued to be extracted twice, all the supernatants were mixed, the pH was adjusted to 4.0, and three times of cold acetone was added to precipitate, and the HPLC test results were shown in figure 1 .

[0057] DEAE-silica gel column liquid chromatographic column (20×100mm) for separation and purification, the chromatographic column filler is macroporous silica gel coated with a layer of diethylaminoethyl substituted cellulose on the surface, the pore diameter of macroporous silica gel is 400 ?, and the particle size of the filler is is 60 μm.

[0058] The sample solution is detected by liquid chromatography with a UV detector, the detection wavelength is 210nm, the flow rate is 5mL / min, the gradient: 0%B (A: 10mM T...

Embodiment 3

[0060] Weigh 20g of leech powder (activity 160ATU / g) produced by Nanning Jinhai Kekang Pharmaceutical Technology Co., Ltd., add 20ml of ultrapure water, 20ml of 5%TCA (PH 1.15), centrifuge at 8000r / min for 15min, and supernatant for later use ;The precipitation continued to be extracted twice, all the supernatants were mixed, the pH was adjusted to 4.0, and three times of cold acetone was added to precipitate, and the HPLC test results were shown in figure 1 .

[0061] DEAE-silica gel column liquid chromatographic column (20×100mm) for separation and purification, the chromatographic column filler is macroporous silica gel coated with a layer of diethylaminoethyl methacrylate polymer on the surface, the pore diameter of the macroporous silica gel is 500 ?, and the particle size of the filler is is 100 μm.

[0062] The sample solution is detected by liquid chromatography with a UV detector, the detection wavelength is 210nm, the flow rate is 5mL / min, the gradient: 0%B (A: 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com