Free-pollution cyclic regeneration pre-treatment technology of waste lubricating oil

A technology of waste lubricating oil and pretreatment, applied in the direction of lubricating composition, etc., can solve the problems of unclear interface, corrosion, difficult separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

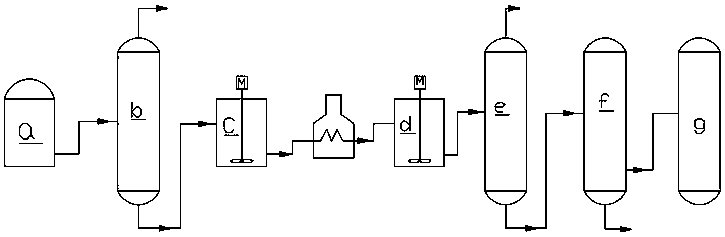

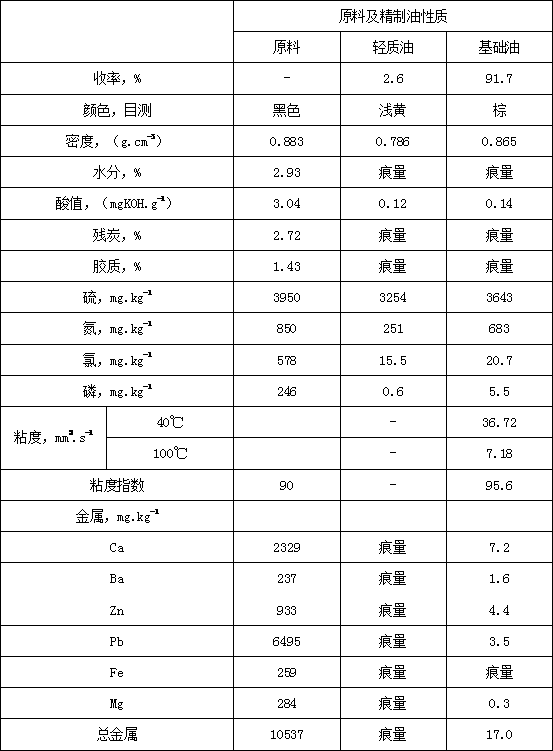

[0029] Such as figure 1 As shown, the waste lubricating oil raw material from the raw material tank a reaches 130°C after heat exchange, and enters the dehydration tower b. After dehydration and impurity removal, the raw material is heat exchanged to 260°C and enters the chemical dechlorination reactor with a stirring device c, carry out dechlorination reaction; the waste lubricating oil is dechlorinated by chemical reaction and then enters the heating furnace, is heated to 370°C and then enters the hydrogen heat treatment reactor d, stays at 370°C for 120min; then enters the heat exchanger and is heat exchanged to 200°C, enter the atmospheric flash tower e to remove light oil; the raw material after light oil removal is heat exchanged to 70°C, and then pumped to 4.8MPa to enter the propane refining unit f, additives in waste lubricating oil and high temperature Condensate produced by oxidation, colloids, asphaltene, metal salts produced by organic acid corrosion of metals, an...

Embodiment 2

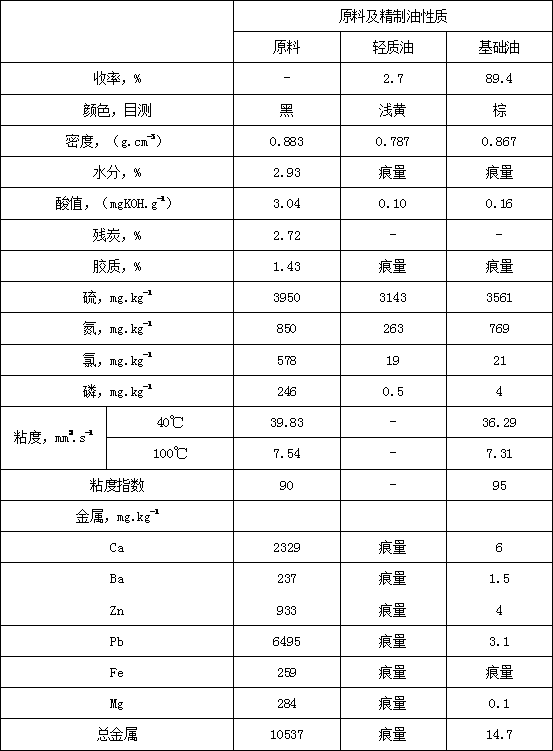

[0031] Such as figure 1As shown, the waste lubricating oil raw material from the raw material tank a reaches a temperature of 130°C after heat exchange, and enters the dehydration tower b. After dehydration and impurity removal, the raw material is heat exchanged to 305°C and enters the chemical dechlorination reactor with a stirring device c, carry out dechlorination reaction; the waste lubricating oil is dechlorinated by chemical reaction and then enters the heating furnace, is heated to 330°C and then enters the hydrogen heat treatment reactor d, stays at 330°C for 60 minutes; then enters the heat exchanger and is heat exchanged to 180°C, enter the atmospheric flash tower e to remove light oil; the raw material after removing water and light oil is heat exchanged to 90°C, and then pumped to 4.5MPa to enter the propane refining unit f, additives in waste lubricating oil And the condensate produced by high-temperature oxidation, colloid, asphaltenes, metal salts produced by o...

Embodiment 3

[0033] Such as figure 1 As shown, the waste lubricating oil raw material from the raw material tank a reaches 130°C after heat exchange, and enters the dehydration tower b. After dehydration and impurity removal, the raw material is heat exchanged to 320°C and enters the chemical dechlorination reactor with a stirring device c, carry out dechlorination reaction; the waste lubricating oil is dechlorinated by chemical reaction and then enters the heating furnace, is heated to 380°C and then enters the hydrogen heat treatment reactor d, stays at 380°C for 90 minutes; then enters the heat exchanger and is heat exchanged to 230°C, enter the atmospheric flash tower e to remove light oil; the raw material after light oil removal is heat-exchanged to 95°C, and then pumped to 5.5MPa to enter the propane refining unit f, additives in waste lubricating oil and high temperature Condensate produced by oxidation, colloids, asphaltene, metal salts produced by organic acid corrosion of metals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com