Fan blade for industrial fan

A technology of fan blades and fans, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problems of fan energy efficiency ratio to be improved, and achieve reduced resistance and fan efficiency Improvement, airflow noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

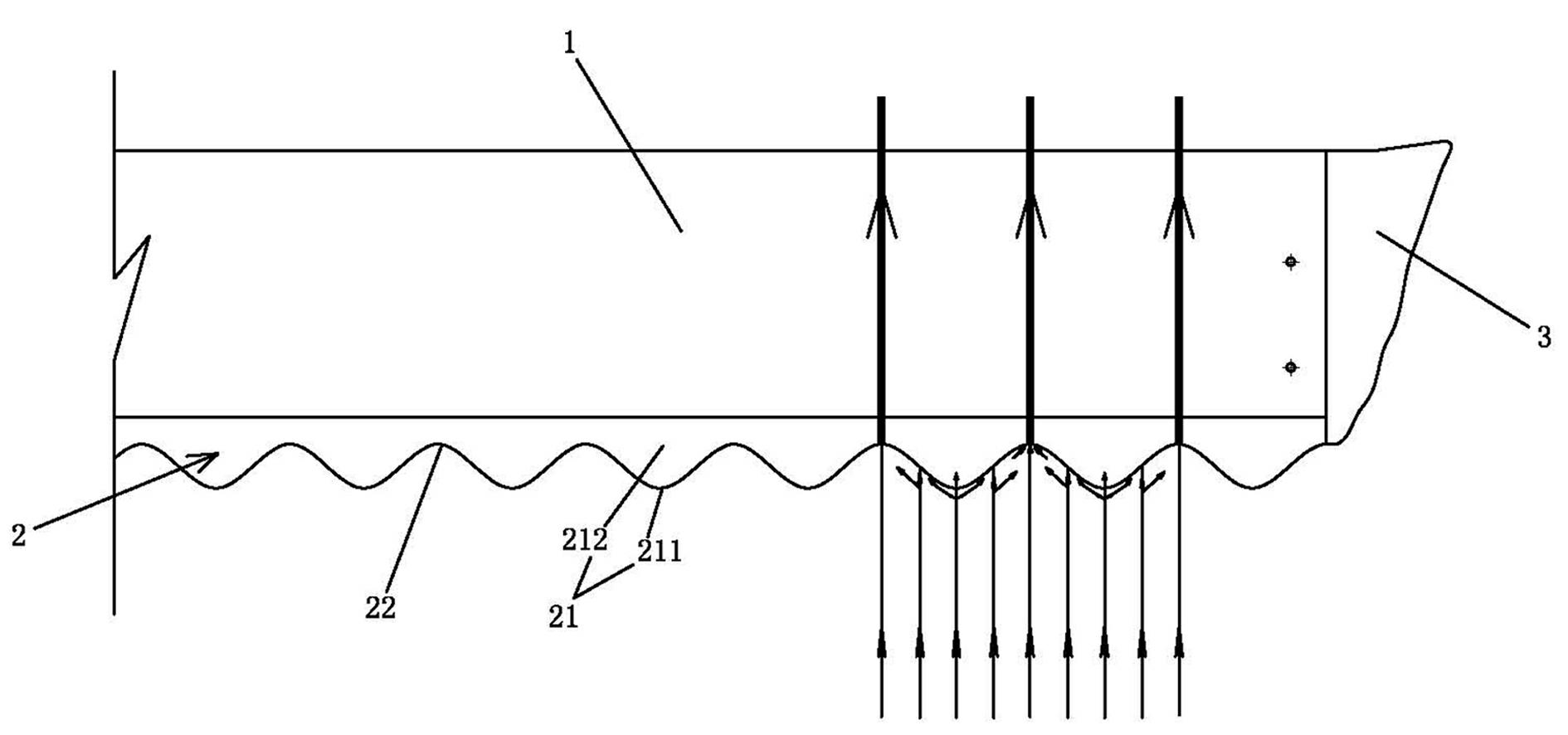

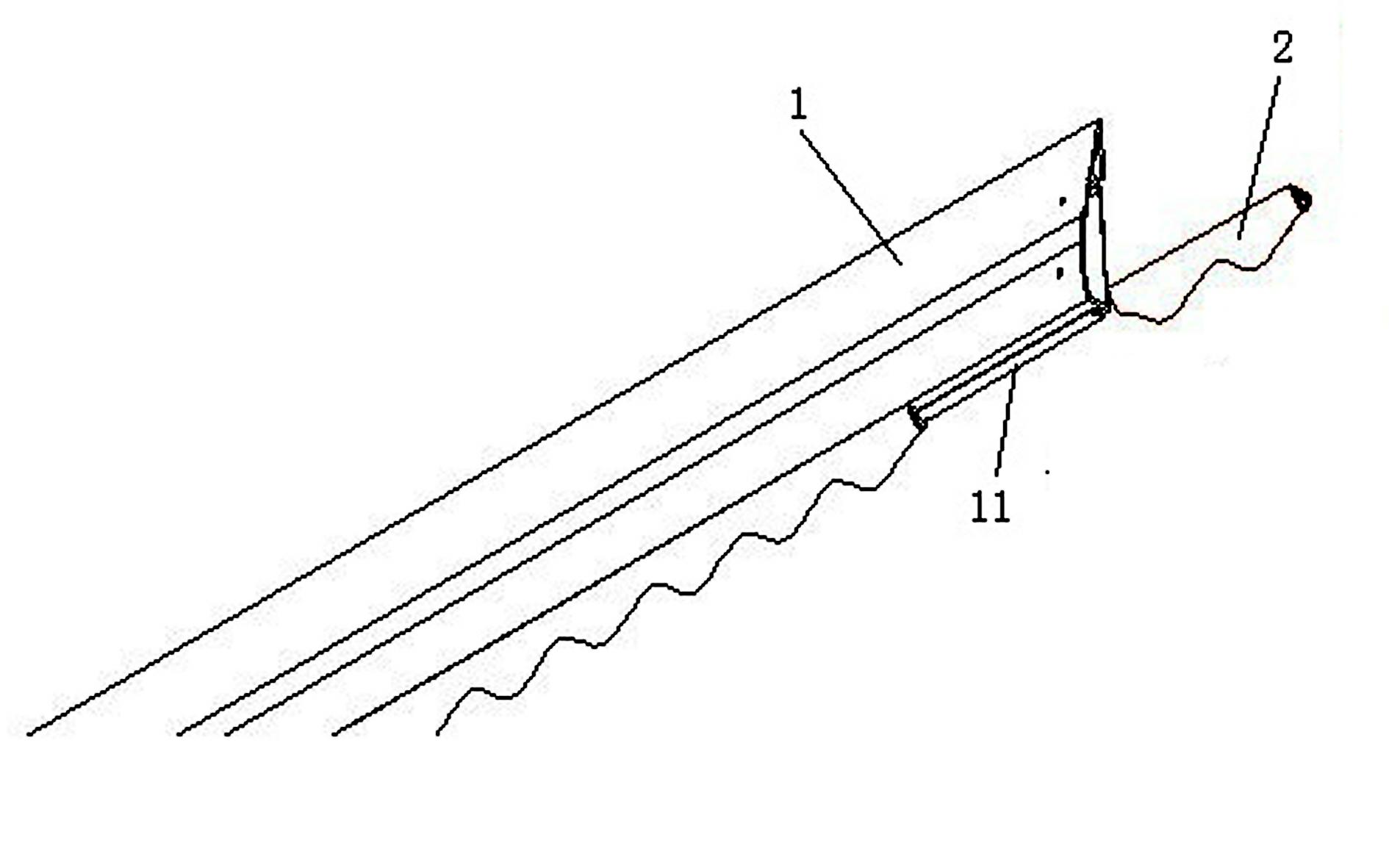

[0012] Such as figure 1 As shown, the blade of the industrial fan in this embodiment includes a blade body 1 , and a gas deflector 2 is installed on one side of the blade body 1 . Such as image 3 As shown, the specific assembly method between the gas deflector 2 and the fan blade body 1 is as follows: the gas deflector 2 is formed with a T-shaped slot (not shown in the figure), and the fan blade body 1 Only the ribs 11 matching with the slots are T-shaped in section; when assembling, snap the ribs 11 on the fan blade body 1 into the slots on the gas deflector 2 .

[0013] The gas deflector 2 is formed with several serrated protrusions 21 distributed along the length direction of the gas deflector, and a serrated valley 22 is formed between every two adjacent serrated protrusions 21 .

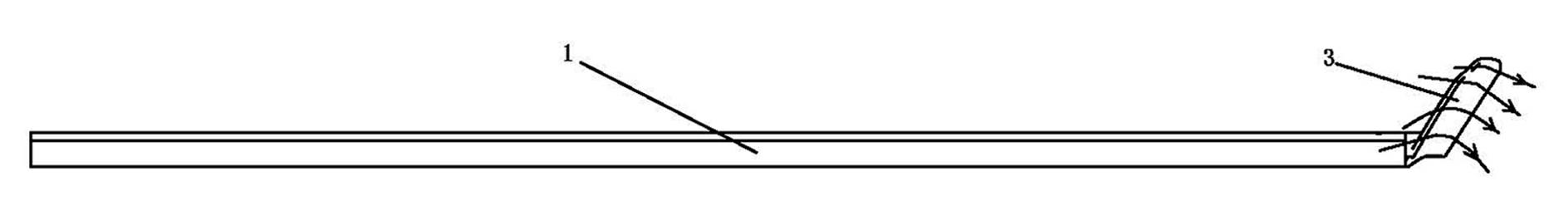

[0014] Moreover, in this example, one end (end) of the fan blade body 1 is also equipped with an outward expansion type winder 3 to eliminate the vortex at the end of the fan blade and achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com