Air curtain system for improving imaging quality of intelligent slagging-off camera

A technology of imaging quality and camera, which is applied in the field of air curtain system, can solve the problems of camera contamination, imaging reliability and maintainability adverse effects, and achieve the effects of reducing maintenance times, improving imaging quality, and enhancing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

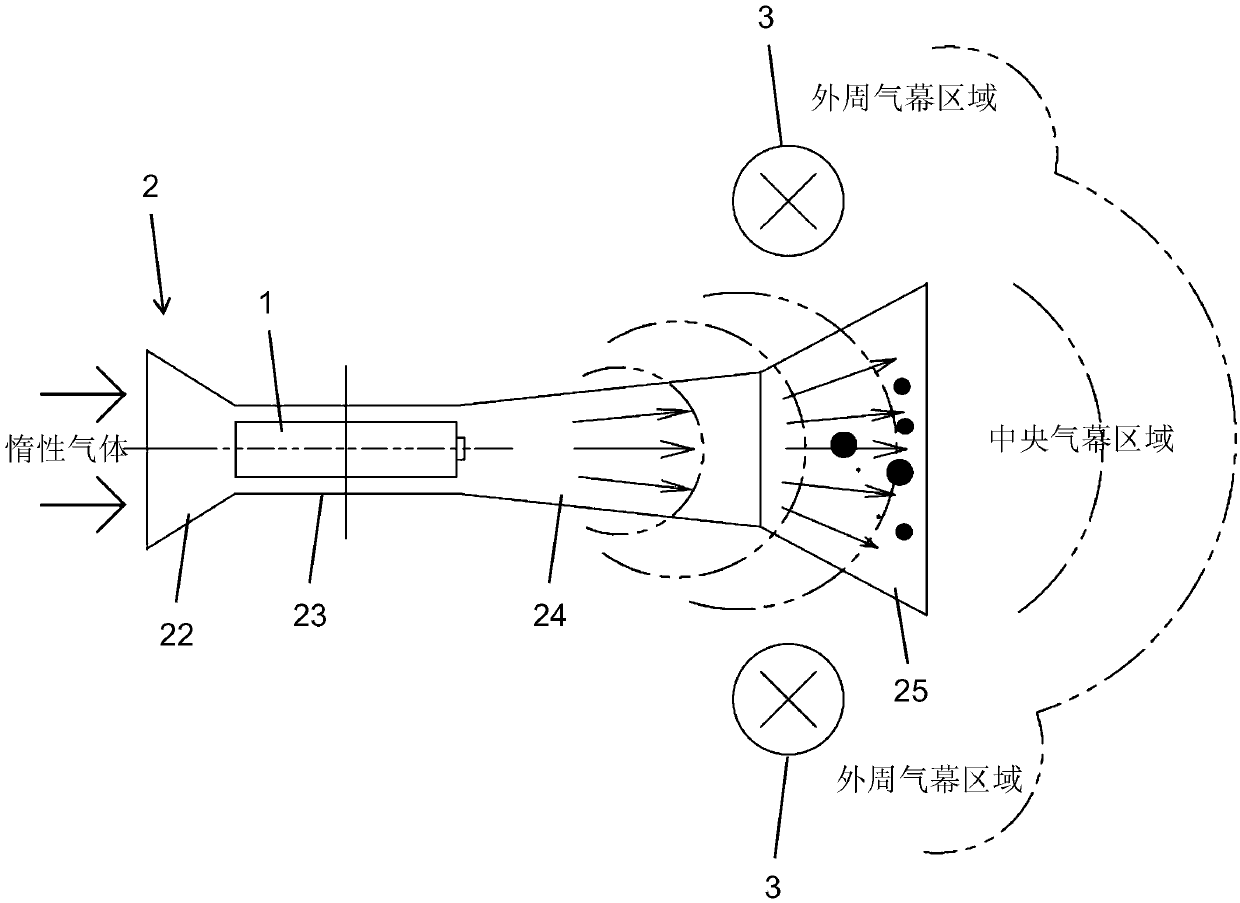

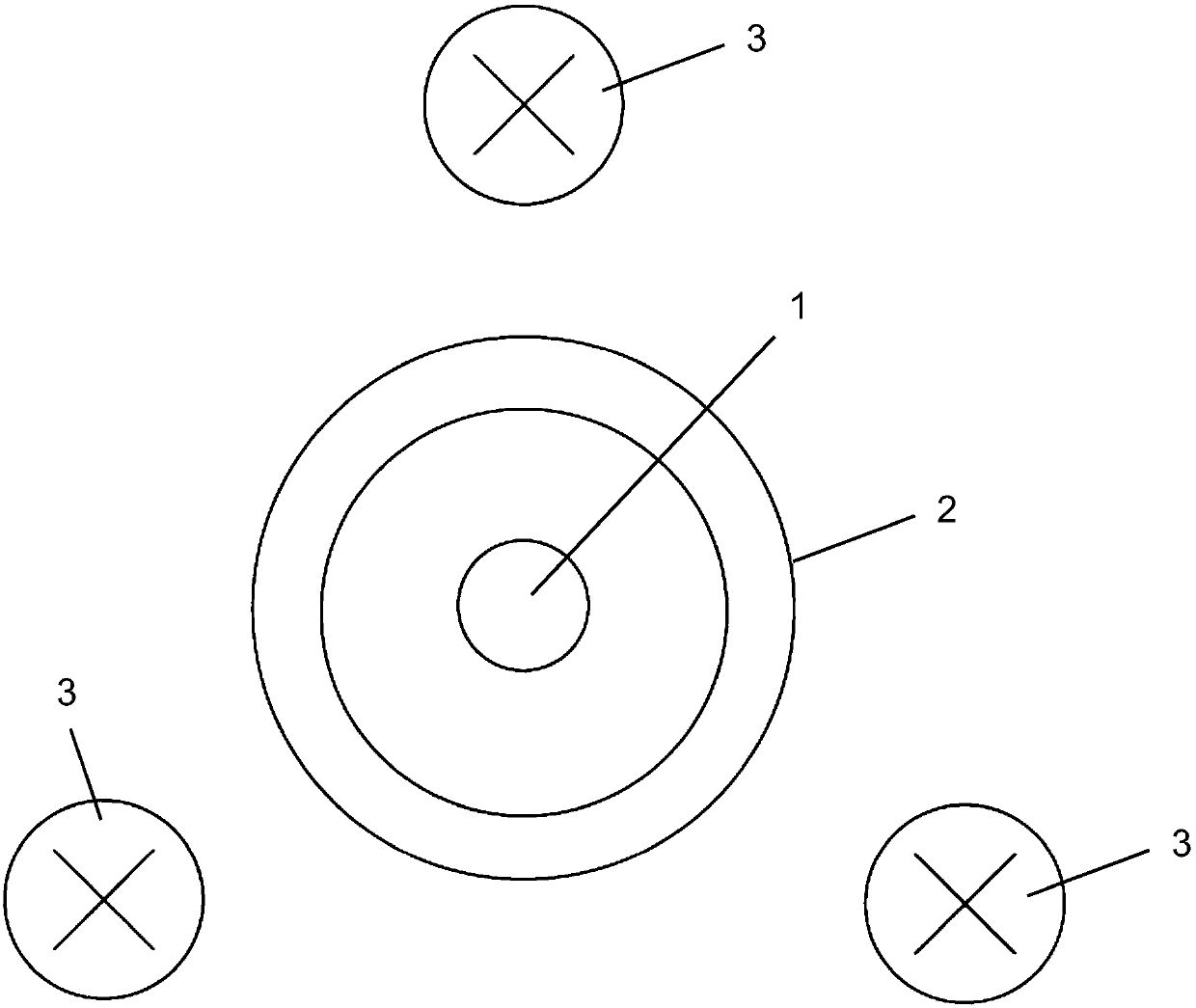

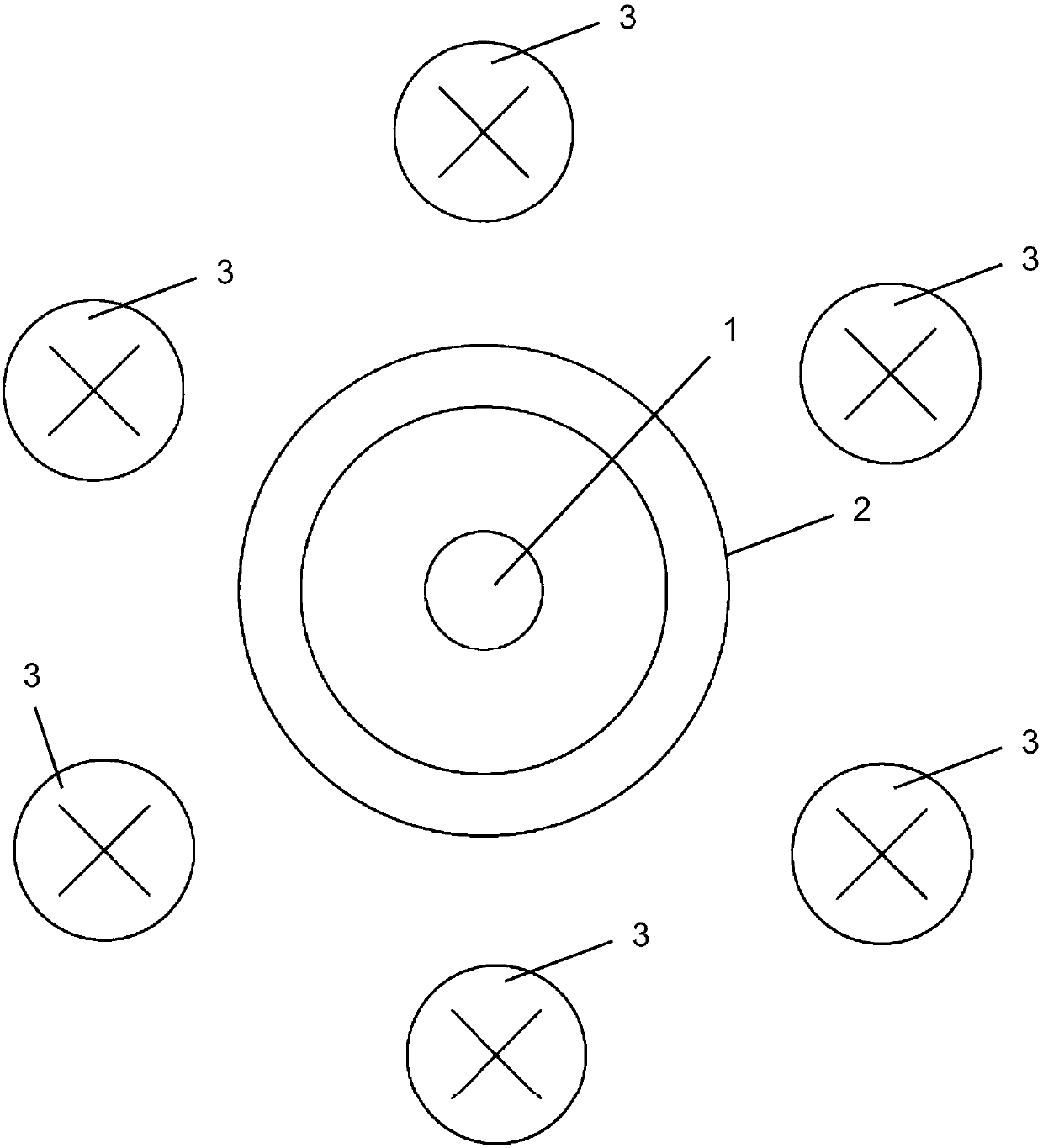

[0032] Please combine Figure 1 to Figure 3 As shown, the air curtain system for improving the imaging quality of the intelligent slag removal camera provided by the present invention includes: a camera body 1, and an external gas source, the external gas source adopts inert gas, and the inert gas is argon or nitrogen. The air curtain system of the present invention also includes: an airflow accelerating device 2 and several industrial fans 3 .

[0033] Preferably, the airflow acceleration device 2 is in communication with the external air source, and is designed as a multi-section cylindrical zoom-type airway. The airflow acceleration device 2 includes: a constriction section 21, a throat section 22, and an expansion section connected in sequence. Anterior segment 23 and expanded posterior segment 24 .

[0034] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com