Noise reduction device for industrial fan

A fan and noise reduction technology, which is applied to parts of pumping devices for elastic fluids, pump devices, mechanical equipment, etc., can solve problems such as motor failure, obvious, burnt, etc., reduce manufacturing costs, ensure working environment, The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

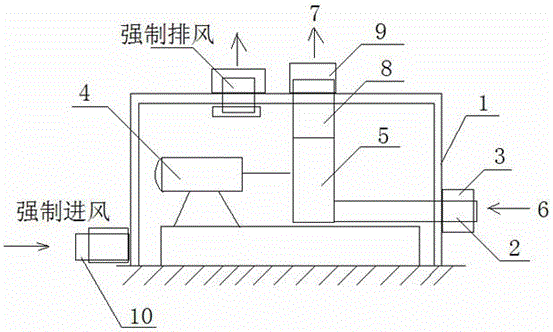

[0014] Such as figure 1 As shown, in the structure adopted in the prior art, the sound-absorbing and insulating room 1 is provided with an air inlet pipe 2 near the side of the fan 5, and the air inlet pipe 2 is connected to the air inlet 6 of the fan, and the air inlet muffler 3 is installed on the air inlet pipe 2. The air outlet muffler 9 is installed on the air outlet pipe 8, the heat dissipation air inlet pipe 10 is installed on the motor side, the air inlet muffler is installed on the heat dissipation air inlet pipe 10, the forced air exhaust pipe is installed on the top of the sound insulation room 1, and the heat dissipation is installed. The fan performs forced exhaust, and a muffler is installed on the forced exhaust pipe. It can be seen that in the existing technology, the structure is assisted, the equipment investment is large, and the forced fan is required, which consumes a lot of energy. Moreover, the temperature in the sound absorption and insulation room is k...

Embodiment 2

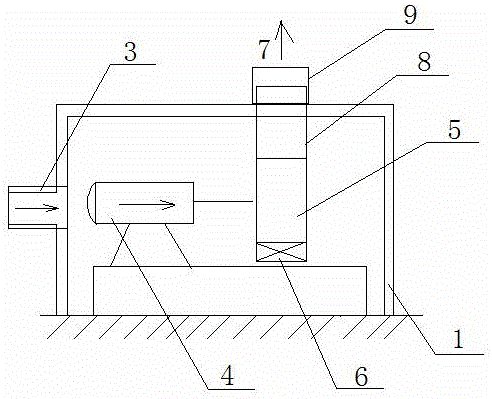

[0021] For some extreme cases, such as when circulating air is used, such as figure 1 The air inlet pipe of figure 2 The air inlet of the fan, when the fan is working, it will enter the air from the air inlet of the fan and the air inlet pipe. figure 2 The set air inlet and air inlet muffler structure will still generate negative pressure through the suction of the fan air inlet to take away the heat of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com