Modular containment unit

a containment unit and module technology, applied in the field of modules, can solve the problems of affecting firefighting, search and rescue, short-term activities, and inability to carry out, and achieve the effects of reducing the risk of firefighting, demolition, repair, or occupation of surrounding areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

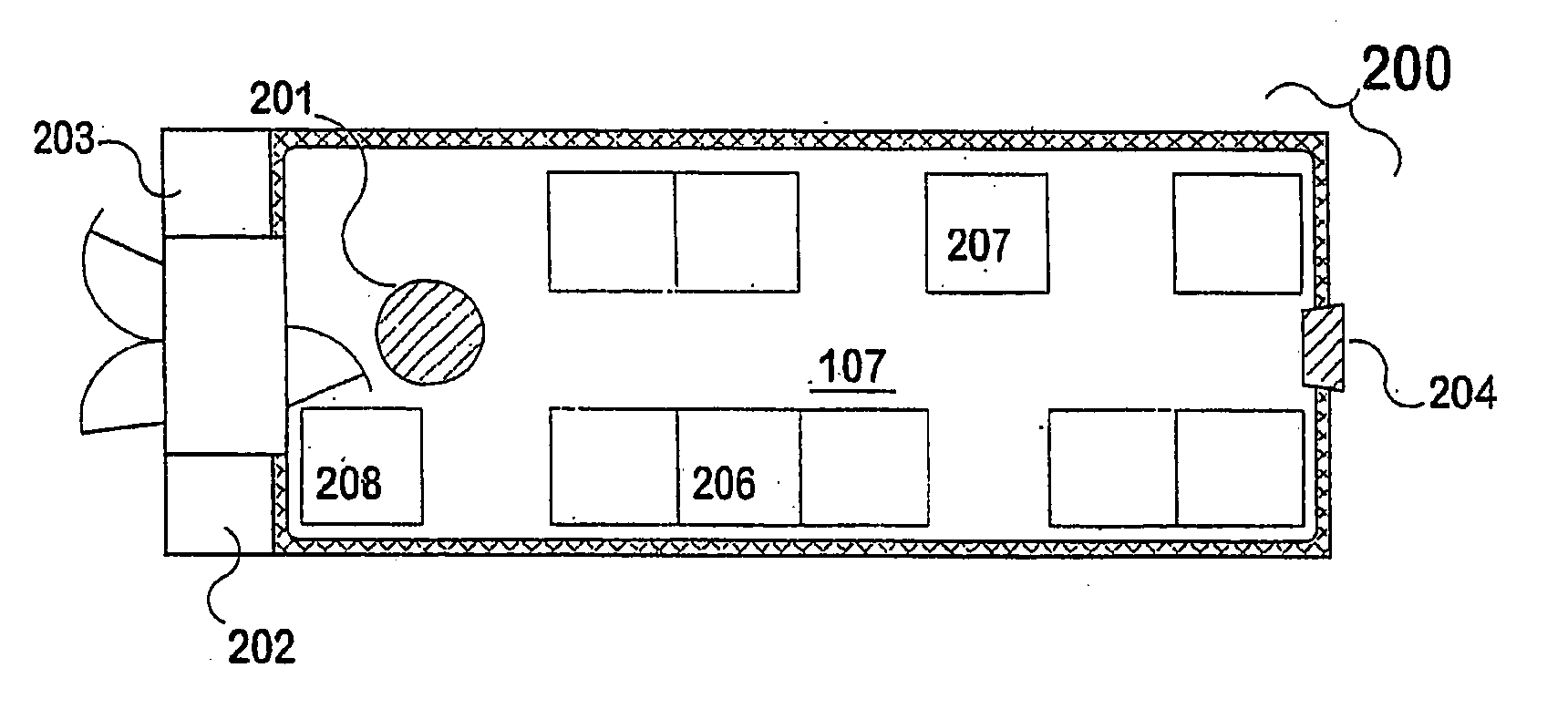

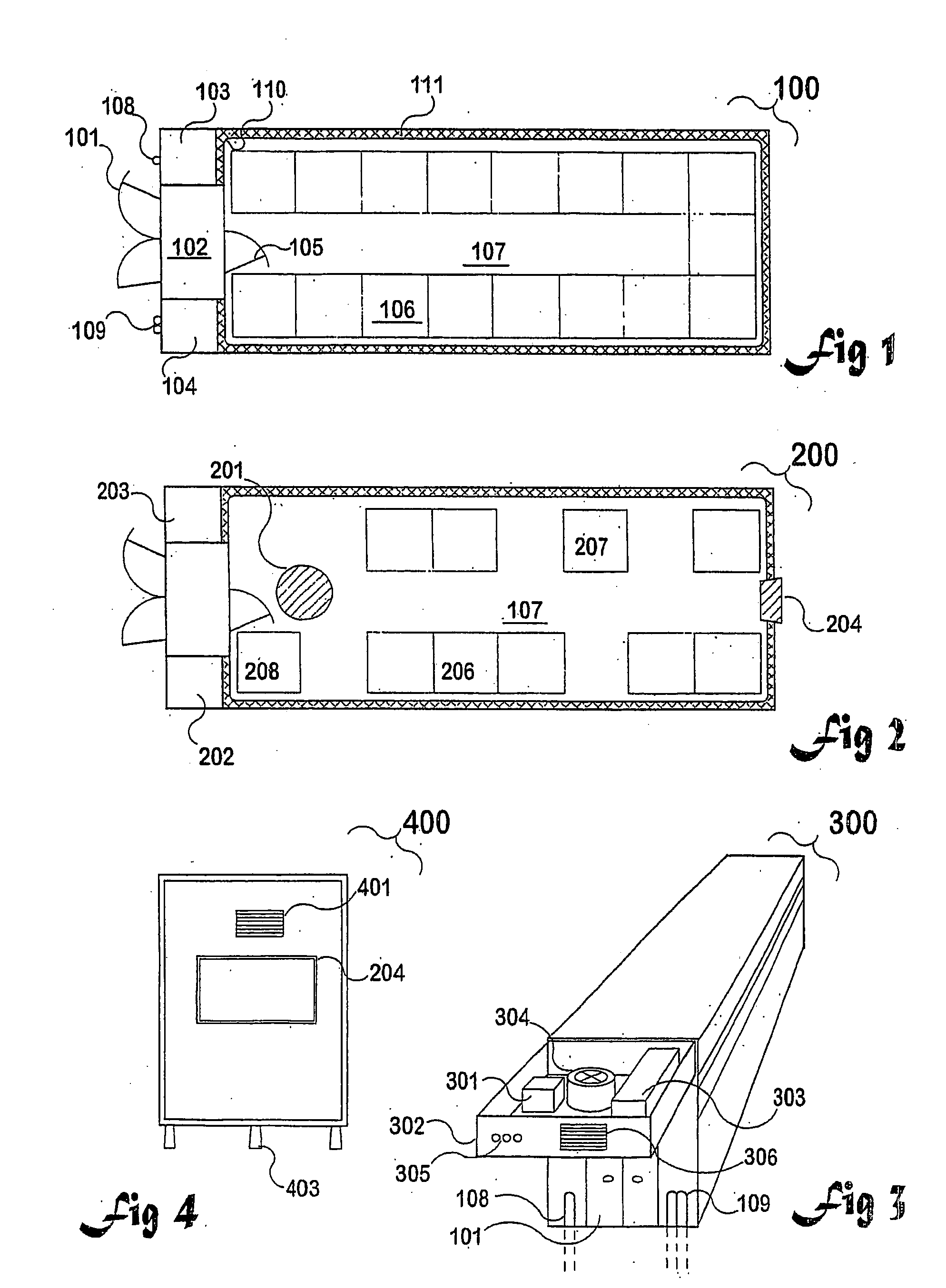

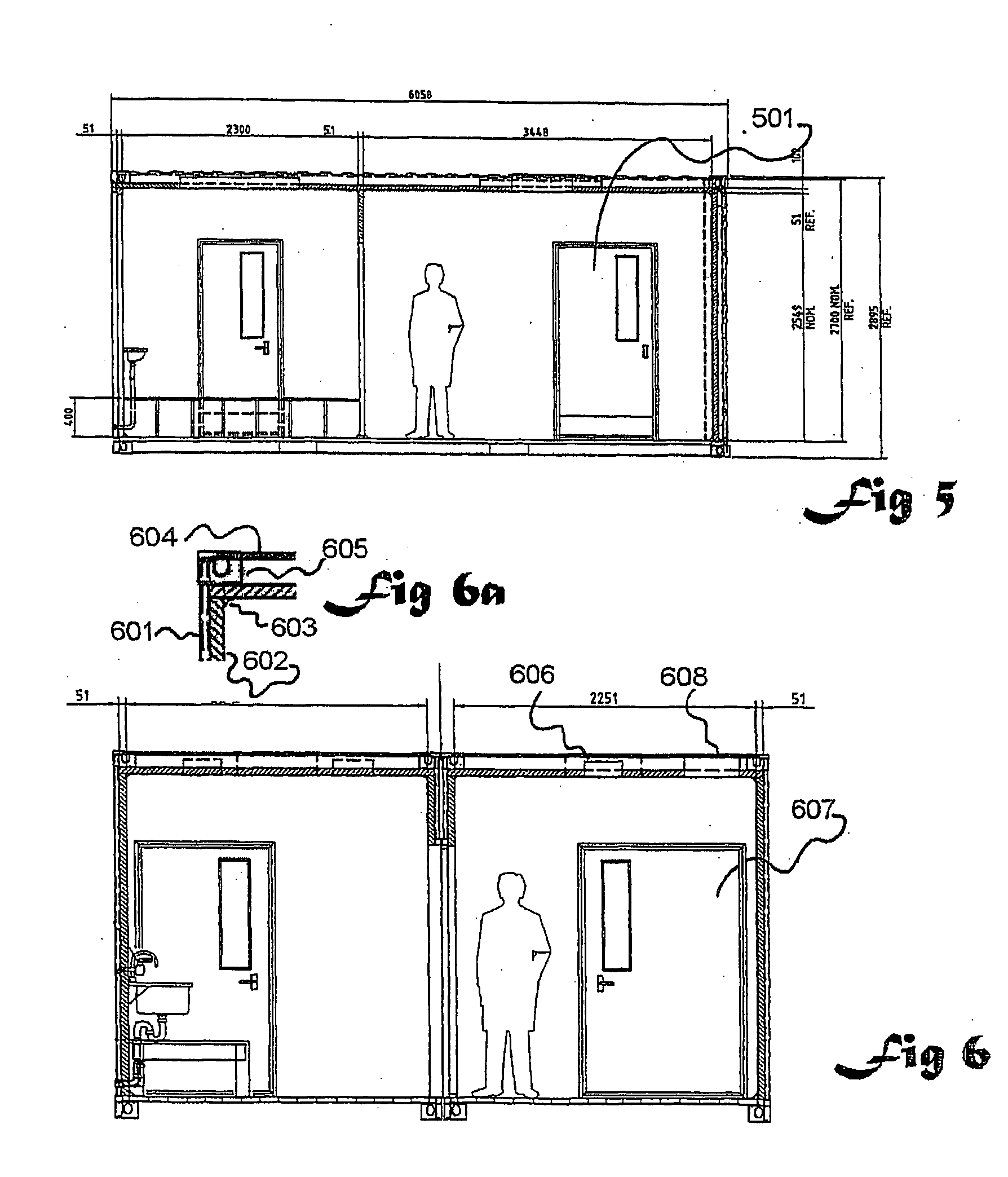

example 1

[0076] The construction of shipping containers has been more or less standardised over many years. Because their primary purpose is to hold and protect goods during shipment, even if exposed on a ship's deck and if underneath a stack of 5 or 6 other containers, they are weatherproof, strong, and are as cheap as their commodity nature allows. See FIGS. 1 to 8. The first aspect of the present invention is to use a shipping container 100 as the outer shell of a specialised working space capable of meeting or exceeding standard requirements relating to factors such as the ingress or egress of microorganisms. A business comprising the manufacture at a site of numbers of such laboratories to meet global standards and then transporting them like ordinary shipping containers, to various destinations would allow experience gained in meeting those standards to be replicated. Otherwise, each individual site has to learn how to meet the relevant standard(s) with greater difficulty. Then, if eac...

example 2

[0105] It is feasible and often advisable to construct a highly demanding environment such as a P3 or P4 laboratory with all the inherent intelligence that is possible. “Intelligent buildings” is a broad term, which can be interpreted as providing one or more of the following options, depending on the level of automation / auditing / monitoring required: [0106] 1. Lighting which can be adjusted according to the needs of a task at a position, and / or which can be configured to switch itself off when not required, so as to optimise resources. [0107] 2. Heating or cooling which is also configurable according to needs, leading to both optimised resources and reduced risk of temperature variance (i.e., to assist in production / lab environments where maintaining a constant temperature is vital to results). [0108] 3. Input systems enabling hands-free interaction with the building controls. For example, if a person has gloved hands, is dressed in an isolation suit, or is otherwise unable to easil...

example 3

[0115] The invention is applicable to packaging of pharmaceuticals, such as where live vaccines are involved or where bacteria or their spores are pressed into tablets. Of particular relevance is the ability to sterilise the entire working environment after completing manufacture or packing one product line, and before commencing work on the next product line. Otherwise, organisms from previous operations may still be present within the working environment and can be found within subsequently produced product lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com