High-efficiency refrigeration industrial fan

An industrial and high-efficiency technology, applied in applications, household heating, household appliances, etc., can solve problems such as general cooling effect, unfavorable resource sustainable development, and inability to realize efficient resource utilization, so as to improve work efficiency and reduce control difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

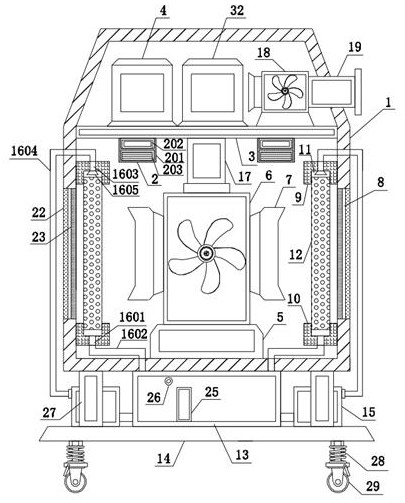

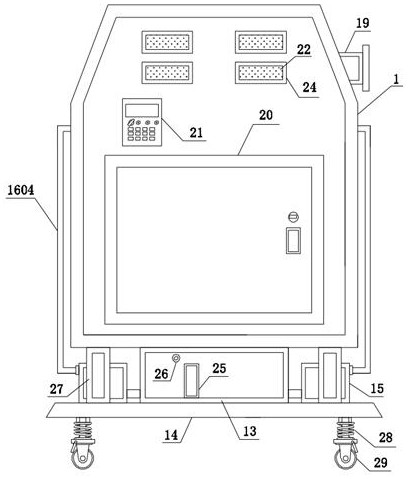

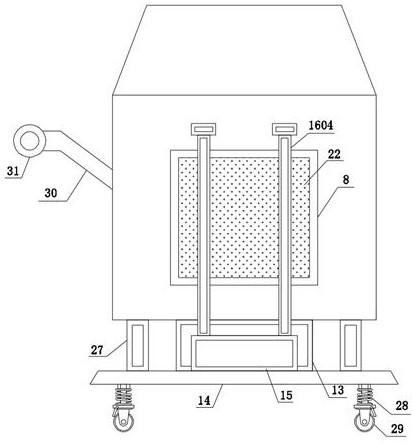

[0036] see Figure 1-5 , a high-efficiency refrigeration industrial fan, comprising a body 1, a sterilizing mechanism 2 is fixedly installed inside the body 1, a partition 3 is fixedly connected to the inner middle end of the body 1, and evaporators are fixedly installed on the left and right sides of the top of the partition 3 4 and condenser 32, the inner bottom of the body 1 is fixedly connected with a receiving seat 5, and the top of the receiving seat 5 is fixedly installed with an exhaust fan 6, and the left and right sides of the exhaust fan 6 are provided with exhaust ports 7, and the left and right sides of the body 1 Both sides are provided with an air inlet 8, the upper ends of the left and right sides of the body 1 are fixedly connected to the upper ends of the air inlets 8, and the lower ends of the left and right sides of the body 1 are fixedly connected to the lower ends of the air inlets 8. 10, the bottom of the upper fixing seat 9 and the top of the lower fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com