Cooling process for production of shielding tape

A cooling process and adhesive tape technology, applied in applications, belts, household appliances, etc., can solve the problems of destroying the internal structure, product quality decline, etc., and achieve the effect of simple process steps, prolonged residence time, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

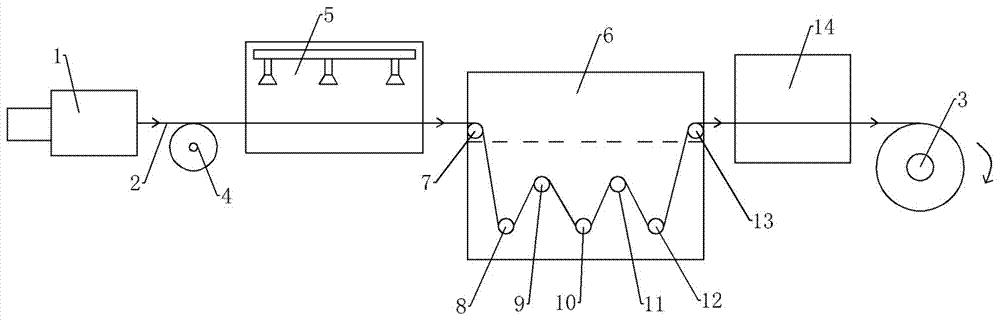

[0023] A cooling process for the production of shielding tapes, comprising the following process steps:

[0024] S1. Feeding: Fix the front end of the shielding tape 2 derived from the outlet of the production device 1 on the winding roller 3, turn on the servo motor connected to the winding roller 3, and the servo motor drives the winding roller 3 to rotate to drive the shielding Forward movement of tape 2;

[0025] S2, spray cooling: the shielding tape 2 enters the spray box 5 through the first guide roller 4 at the exit of the production device 1, opens the water inlet valve and the water pump on the water inlet pipe of the spray box 5, and the Water is evenly sprayed to the surface of the shielding tape 2, wherein the temperature of the sprayed water in the spray box 5 is 20°C, and the preliminary cooling process is completed;

[0026] S3, water immersion cooling: the shielding tape 2 that has completed the preliminary cooling process is moved to the water tank 6 by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com