Large industrial fan with fan blade floating dust cleaning function

A blade and functional technology, applied in the field of industrial large fans, can solve the problems of thin structure at the connection between the blade and the fuselage, excessive dust deposition on the surface of the blade, and affecting the use of the fan, so as to reduce installation steps, avoid breakage, The effect of increasing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

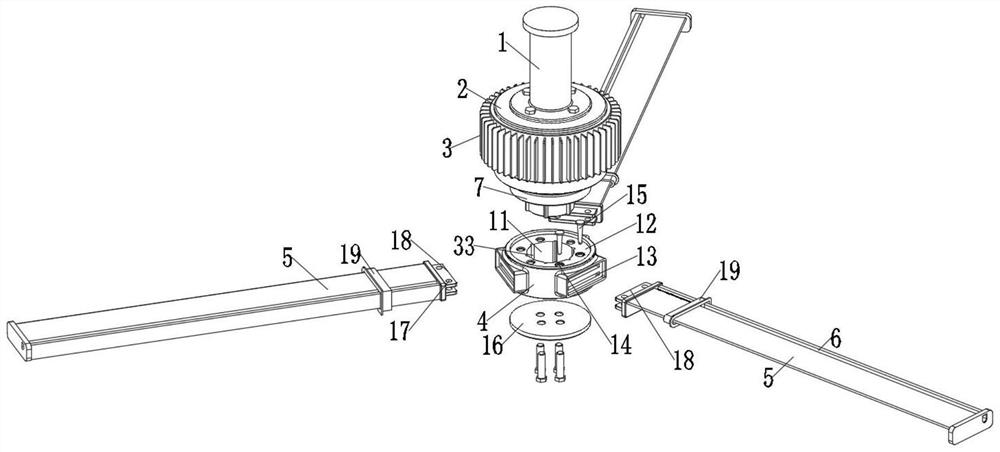

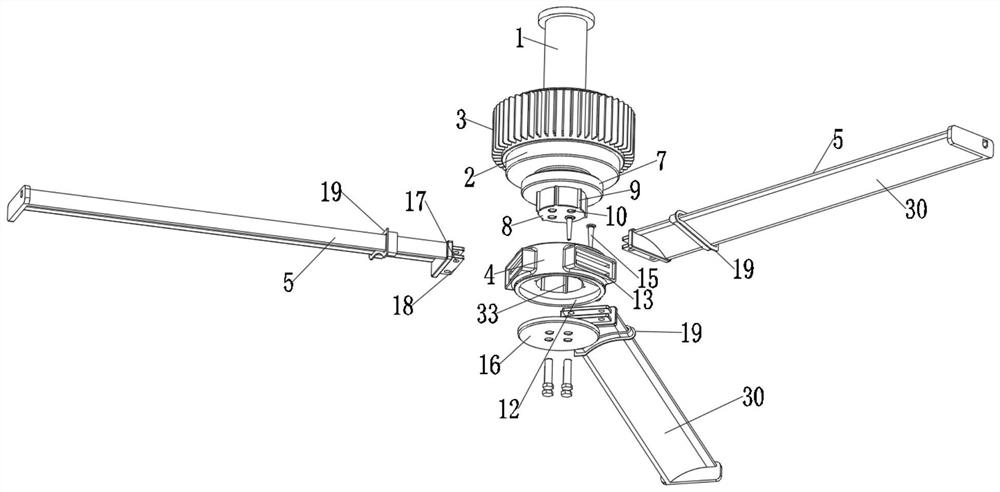

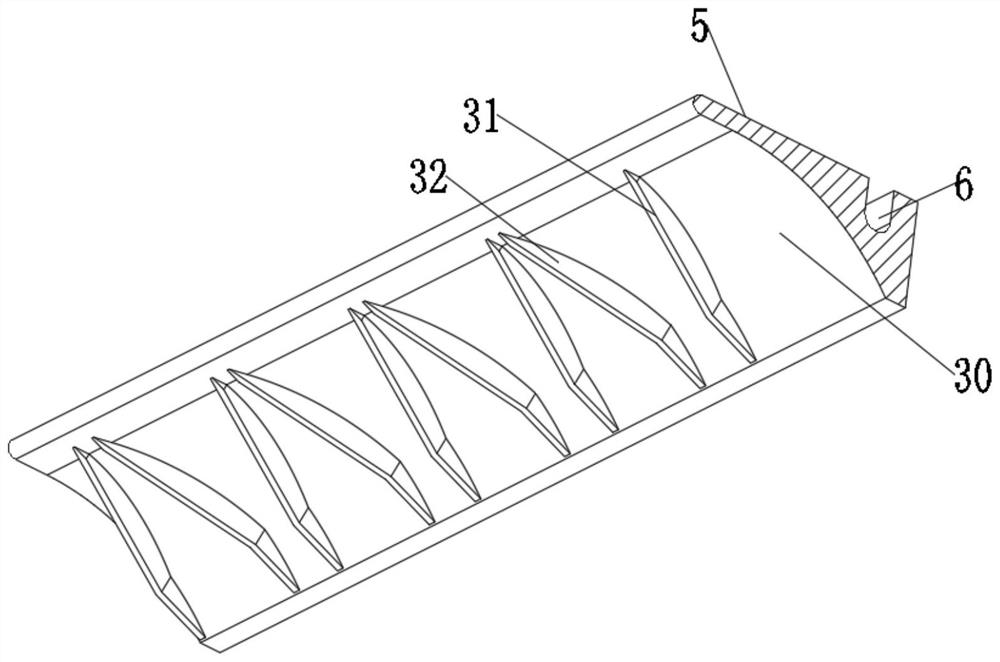

[0028] For large industrial fans, after long-term use, too much dust will be deposited on the surface of the fan blades, which will affect the use of the fan. Please refer to Figure 1-6 , one of which is an industrial large fan with the function of cleaning the dust on the fan blades, including a mounting column 1 and a driving motor 2 under the mounting column 1, the lower end of the driving motor 2 is installed with a revolving frame 7, and the lower end of the revolving frame 7 is provided with a mounting shaft 8. A connecting sleeve 4 is installed on the outer side of the installation shaft 8, a fixing hole 10 is arranged on the lower surface of the installation shaft 8, an insertion pin groove 13 is arranged on the outer side of the connecting sleeve 4, and a flat fan blade is installed inside the insertion pin groove 13. 5. The flat fan blade 5 and the insertion pin slot 13 are fixed by the insertion flat pin 18, the interior of the connecting sleeve 4 is provided with a...

Embodiment 2

[0031] When the sliding sleeve 19 slides for cleaning, it will slide to the top of the flat fan blade 5. When the shaft frame 7 stops rotating, it cannot be reset, and the fan is suspended on the roof, which is extremely difficult and inconvenient for manual operation. This embodiment is in Embodiment 1. Improvements made on the basis of the specific, please refer to Figure 1-6 The interior of the flat fan blade 5 is provided with a limiting groove 6 , and the interior of the flat fan blade 5 is also installed with a shrinking spring 22 located inside the limiting groove 6 , and the shrinking spring 22 is used to connect to one side of the sliding sleeve 19 .

[0032] The sliding sleeve 19 is driven by centrifugal force to slide and clean on the upper surface of the flat fan blade 5, and when the rotation is stopped, the contraction spring 22 will pull it back to its original position for reset processing, which is convenient for multiple cleaning functions.

Embodiment 3

[0034] After the device has been cleaned for a long time, the cleaning structure needs to be replaced to avoid affecting the cleaning efficiency. This embodiment is an improvement made on the basis of Embodiment 2. For details, please refer to Figure 1-6 , the interior of the sliding sleeve 19 is provided with a matching socket 17, and the interior of the sliding sleeve 19 is also installed with a cleaning sleeve 23 located in the matching socket 17.

[0035] Through the clamping structure of the cleaning sleeve 23, the cleaning sleeve 23 can be replaced in a timely manner, so as to avoid cleaning for a long time, resulting in reduced efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com