Rotary bottle blank arrangement system and bottle blank arrangement method

A technology for rotating bottles and preforms, which is applied in the field of the whole-row embryo supply system for preforms, to achieve the effects of improving the utilization rate, maintaining export stability, and improving the utilization rate of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

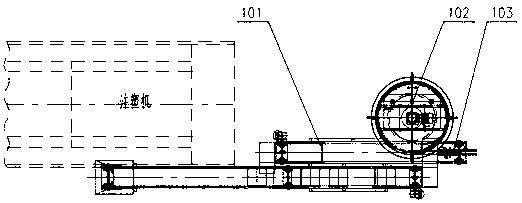

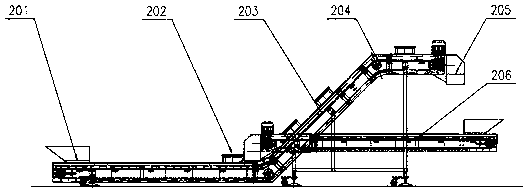

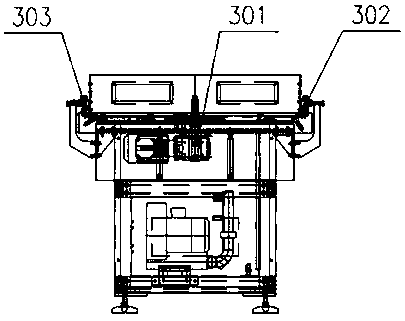

[0017] In the figure: preform conveying part 101, rotating alignment part 102, arranging outlet part 103, preform inlet 201, industrial fan 202, cooling channel 203, net chain conveyor I204, preform outlet 205, net chain conveyor II206, rotary Disk 301, buffer strip 302, preform size adjustment device and support mechanism 303, guide channel 401, automatic preform discharge device 402.

[0018] as attached figure 1 As shown, a rotary preform sorting system of the present invention includes a preform conveying part 101 , a rotating alignment part 102 , and an arrangement outlet part 103 . The function of the conveying part 101 is that under the cooling of the industrial fan, the thermoplastic preform enters the cooling channel from the entrance, and continues to cool down through the mesh chain conveyor. The recovery conveyor returns the excess preforms accumulated at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com