High-strength high-flowability low-warpage long glass fiber reinforced polyamide composite material as well as preparation method and application thereof

A technology of long glass fiber and composite material, which is applied in the field of glass fiber modified polyamide composite material, can solve the problem that the industrial fan blade is not easy to warp and deform, and achieves the improvement of fluidity and appearance of parts, stable use and not easy to warp. warp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

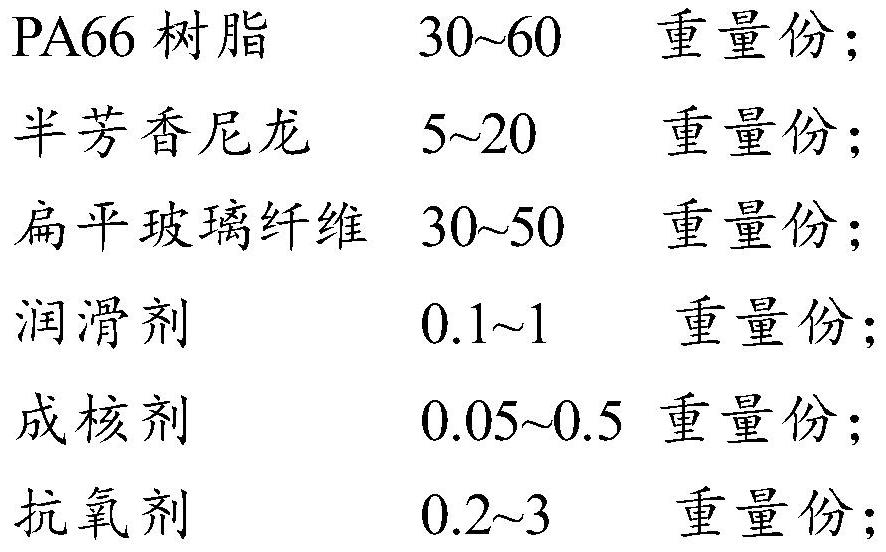

[0084] The invention provides a kind of preparation method of the polyamide composite material reinforced by glass fiber, comprising the following steps:

[0085] 1) After PA66 resin, semi-aromatic nylon resin, lubricant, nucleating agent and antioxidant are mixed, a premix is obtained;

[0086] 2) Put the premixed material obtained in the above steps through twin-screw melt-extruded molten material into an impregnation mold with flat glass fibers placed therein. Fiber reinforced polyamide composites.

[0087] In the present invention, firstly, PA66 resin, semi-aromatic nylon resin, lubricant, nucleating agent and antioxidant are mixed to obtain a premixed material.

[0088] In the present invention, the premixed material obtained in the above steps is melted and extruded by twin-screws, and then sent into an impregnation mold with flat glass fibers, and the molten material is soaked in the flat glass fibers, then released from the mold, and then cooled to obtain Glass fib...

Embodiment 1

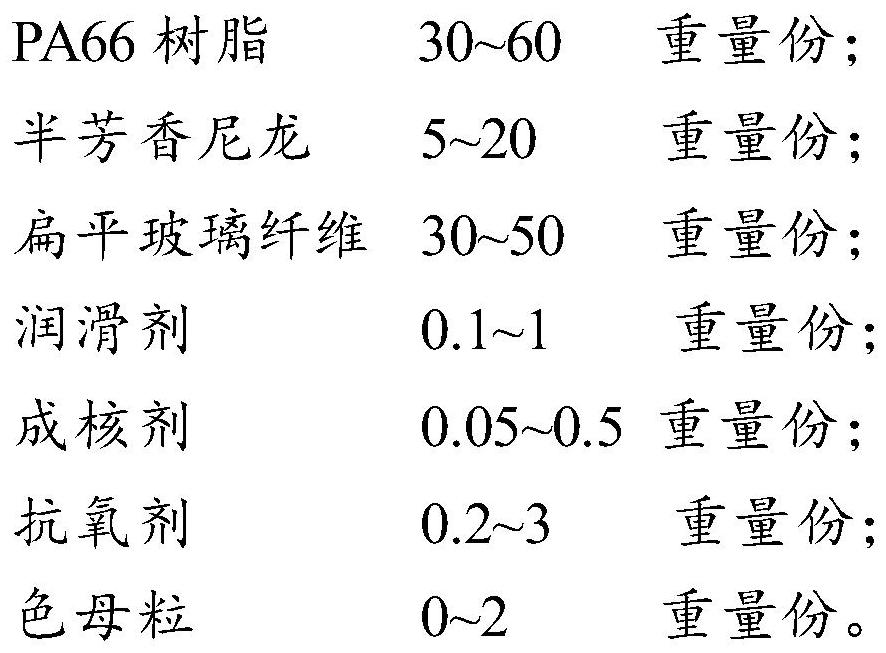

[0109] High-strength continuous flat long glass fiber reinforced PA66 composite material 1, including the following raw materials:

[0110] 49.2 kg of PA66 (polyamide) resin, model PA66-EPR24;

[0111] 16 rolls (4800 pieces per roll) of high-strength continuous flat long glass fiber, the model is ER5301T-2000, the cross-section is flat, the cross-section width-to-thickness ratio is 4:1, and the surface is coated with impregnation with good compatibility with PA66 resin agent;

[0112] 0.15 kg of lubricant is ethylene-acrylic acid copolymer lubricant;

[0113] 10 kg of semi-aromatic nylon resin MXD6 with special chemical structure: synthesized by condensation of m-xylylenediamine and adipic acid;

[0114] 0.15 kg of hindered phenolic primary antioxidant, model Irganox 1098, and 0.15 kg of phosphite antioxidant, model Irganox 168;

[0115] 0.3 kg of black masterbatch, the model is CABOT-PA3785;

[0116] 0.05 kg of nucleating agent, the model is P22.

[0117] The preparation...

Embodiment 2

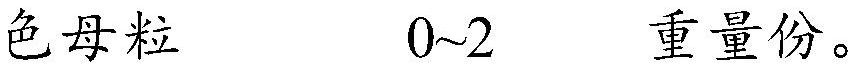

[0124] High-strength continuous flat long glass fiber reinforced PA66 composite material 2, including the following raw materials:

[0125] 59.2 kg of PA66 (polyamide) resin, model PA66-EPR24;

[0126] 16 rolls of high-strength flat long glass fiber, the model is ER5301T-2000, the cross-section is flat, and the width-to-thickness ratio of the cross-section is 4:1;

[0127] 0.15 kg of lubricant is ethylene-acrylic acid copolymer lubricant;

[0128] 0.15 kg of hindered phenolic primary antioxidant, model Irganox 1098, and 0.15 kg of phosphite antioxidant, model Irganox 168;

[0129] 0.3 kg of black masterbatch, the model is CABOT-PA3785.

[0130] 0.05 kg of nucleating agent, the model is P22.

[0131] The preparation method of high-strength continuous flat long glass fiber reinforced PA66 composite material 2, prepares raw materials according to the above weight;

[0132] Step 1: High-strength continuous flat glass fiber model ER5301T-2000;

[0133] Step 2: 59.2 kilograms o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com