Polyethylene coated steel pipe, online production and equipment thereof

A technology of polyethylene and polyethylene tape, applied in the direction of mechanical equipment, pipes, rigid pipes, etc., can solve the problems of increasing the purchase cost of anti-corrosion equipment, increasing the auxiliary cost of anti-corrosion coating, and weak bonding, so as to reduce auxiliary costs and The cost of steel pipe anti-corrosion coating, the effect of reducing the cost of pipeline anti-corrosion coating and avoiding multiple transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

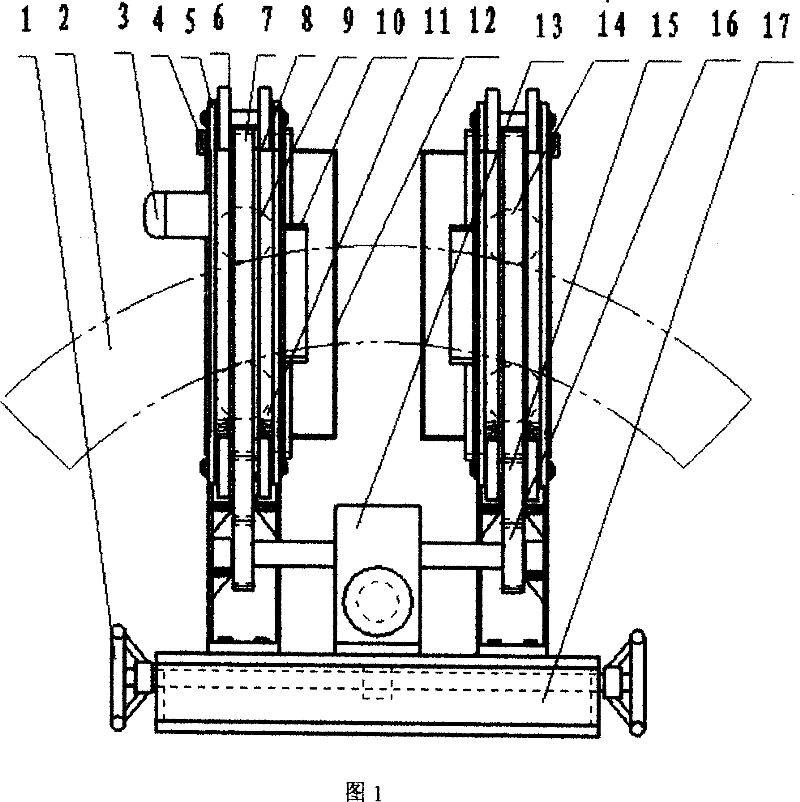

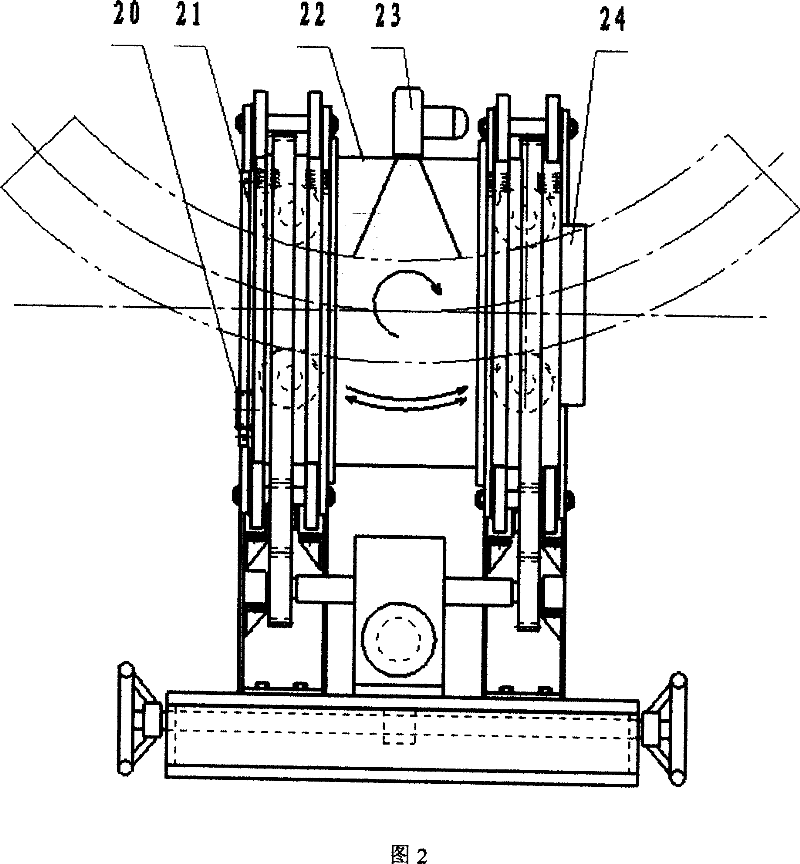

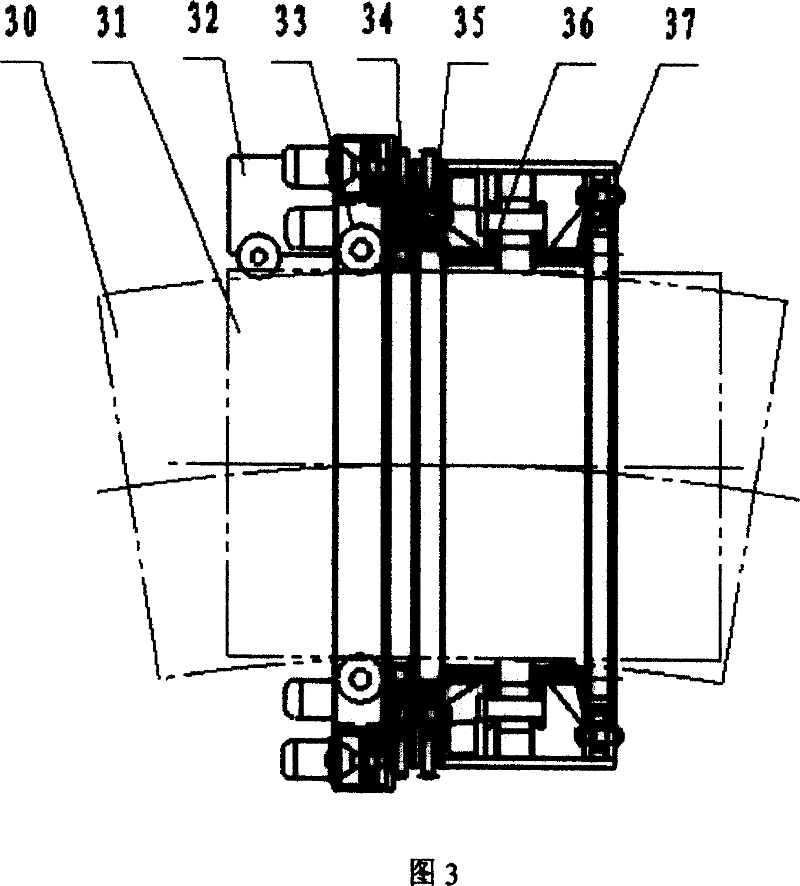

[0029] The following examples are used to illustrate the polyethylene-coated steel pipe, the online production method and production equipment of the present invention.

[0030] The online production method of polyethylene coated steel pipe of the present invention includes:

[0031] (a) The steel pipes that have passed the visual inspection are put into the steel pipe shot blasting machine;

[0032] (b) Start the high-frequency induction heating power supply, and the high-frequency induction heating coil will heat the outer surface of the steel pipe in a very short time;

[0033] (c) Start the steel pipe shot blasting machine to make the steel pipe a reciprocating spiral movement;

[0034] (d) Start the shot blasting machine, and the shot blasting head sprays steel shot and steel grit to the steel pipe at high speed, impacts off the rust spots on the outer surface of the steel pipe, and strikes an anchor pattern on the outer surface of the steel pipe;

[0035] (e) The shot blasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com