Industrial fan volute

An industrial, volute technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., which can solve problems such as difficulty in drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

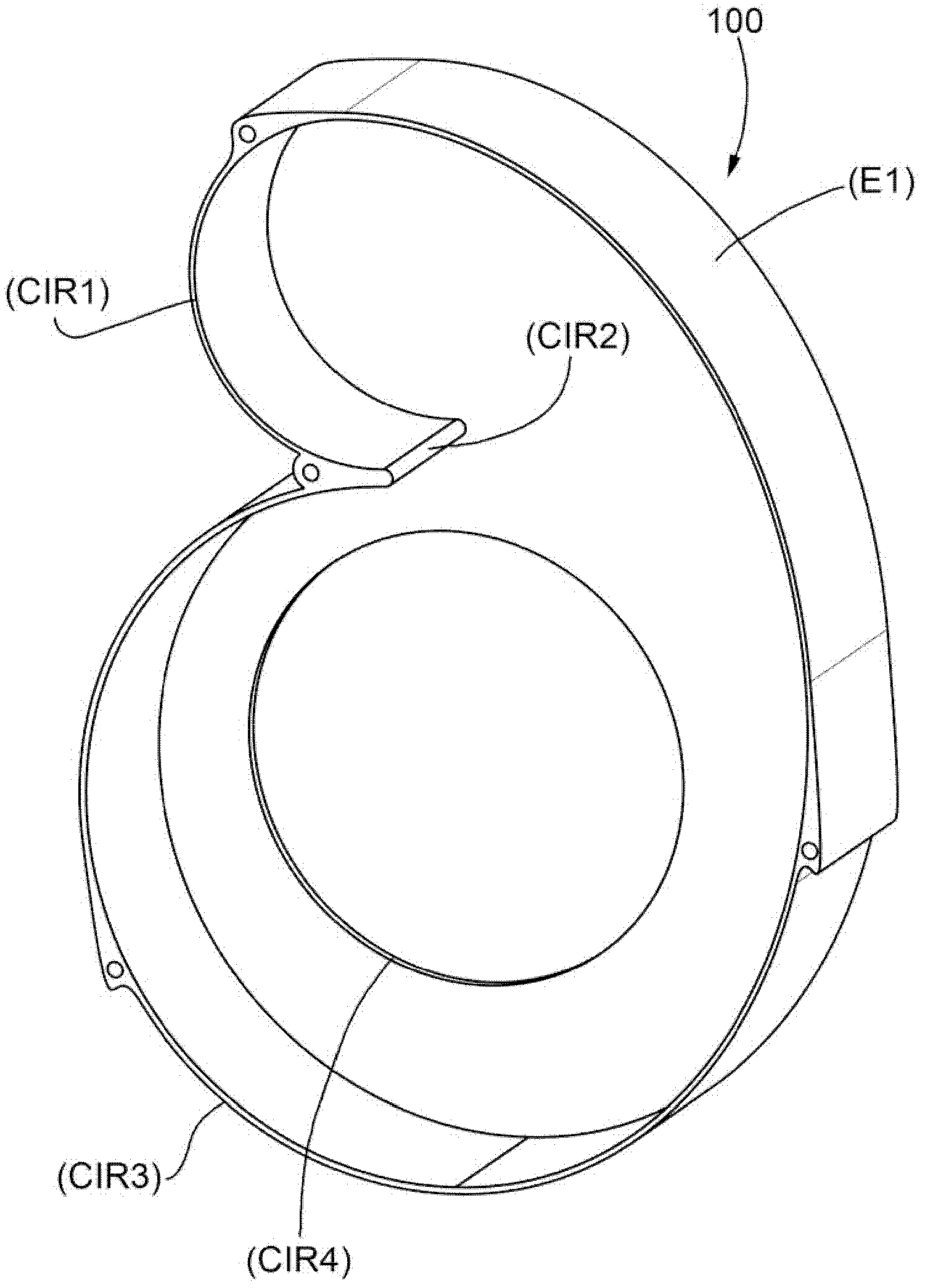

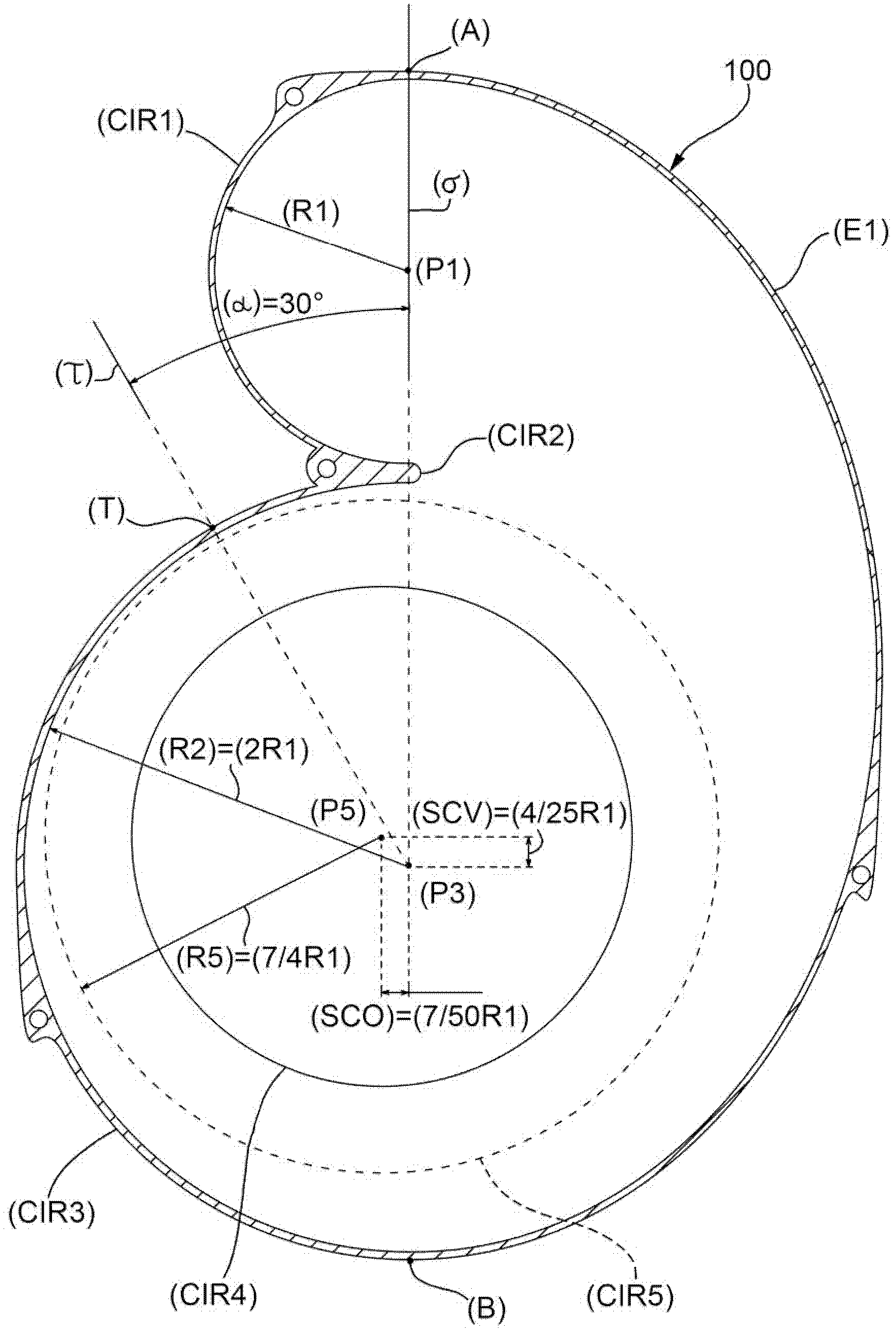

[0016] figure 1 The reference number 100 in represents generally a fan volute according to the teachings of the present invention.

[0017] In the example shown, the volute has an air inflow perpendicular to the larger circular area (as is often the case in centrifugal fans) and an air outlet perpendicular to the smaller circular area (However, this is usually not the case).

[0018] As is known from the technical literature on the subject, this design provides greater axial compactness of the volute (ie, perpendicular to the circular area).

[0019] As explained in more detail below, the hole in the bottom of the volute at the larger circular area serves as a mount for components of the electric motor that powers the fan wheel.

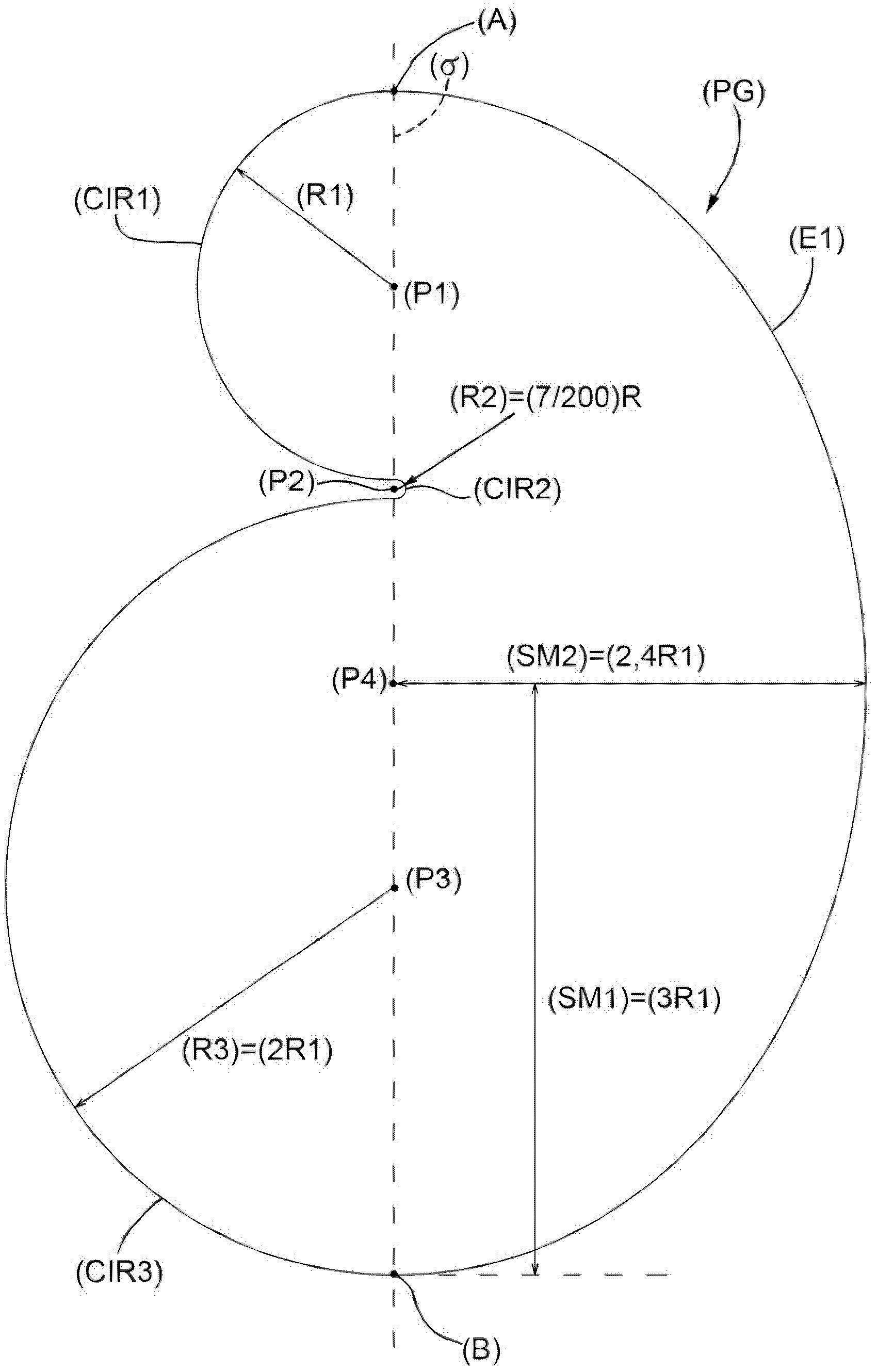

[0020] figure 2 A plan view of the geometric profile (PG) of the volute 100 is shown.

[0021] Geometric Profiles (PG) include:

[0022] - a semicircle (CIR1), having a center (P1) and a radius (R1), said semicircle defining a circular air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com