Gradient multi-layer protective coating capable of resisting erosion of solid particles and preparation method of gradient multi-layer protective coating

A protective coating and solid particle technology, applied in the coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems that affect the anti-erosion performance of the coating, cannot achieve anti-erosion effect, high heat, etc. , to achieve the effect of being conducive to industrial production and application, easy to uniformly deposit large areas, and simple and easy to control the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

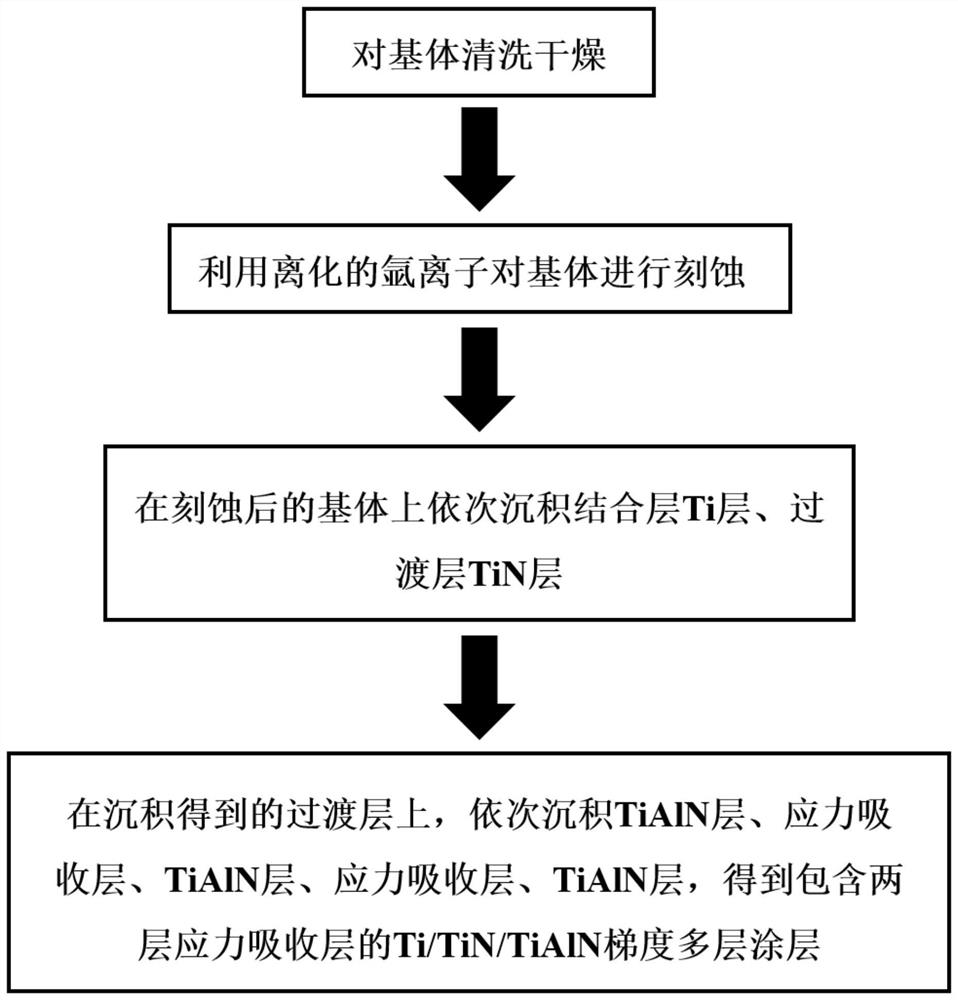

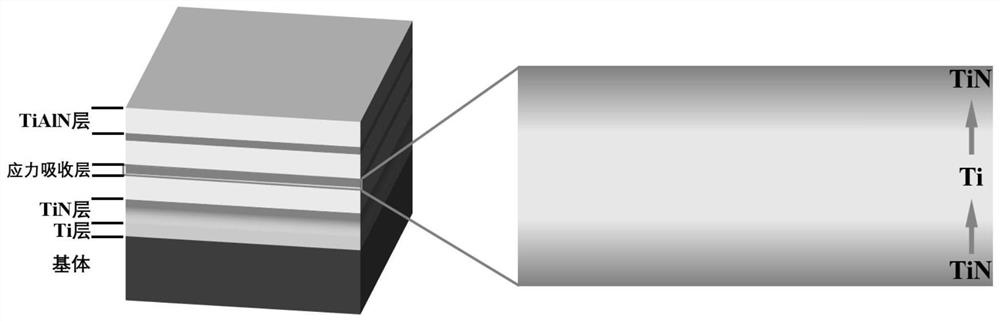

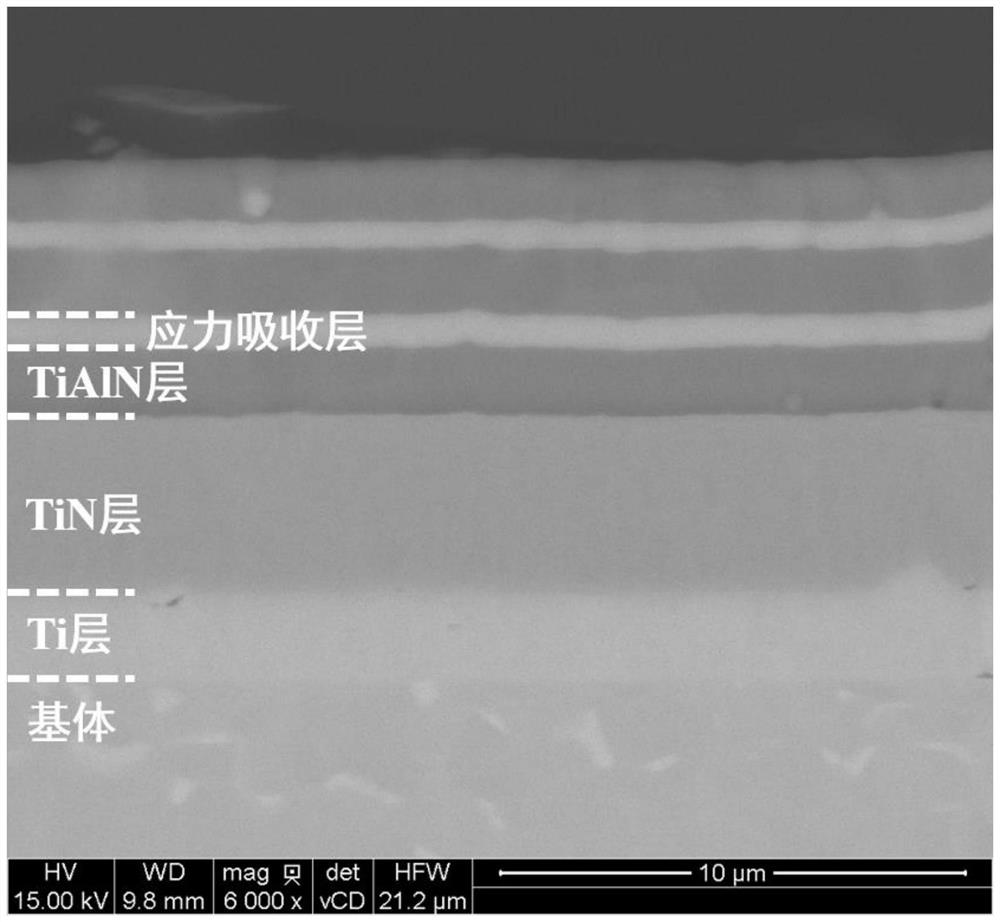

[0055] The invention provides a preparation method of a gradient multi-layer protective coating resistant to erosion of solid particles, such as figure 1 shown, the specific steps are as follows:

[0056] (1) Step 1. Use degreaser, acetone and anhydrous ethanol to clean the titanium alloy substrate in sequence, put the cleaned and dried titanium alloy substrate into the vacuum chamber, and first pass argon gas 35.0 into the vacuum chamber. sccm, set the current of the linear anode ion source to 0.2A, the chamber pressure to 0.2Pa, and use ionized argon ions to etch the substrate for 30min; then use arc ion plating technology to deposit the Ti binding layer, the target material is Ti target, the substrate The negative bias voltage is -70V, the arc current is 70A, the Ar gas pressure is 6.0Pa, and the deposition thickness is 2.0μm;

[0057] (2) Then adopt the arc ion plating technology to deposit the TiN transition layer, feed the reaction gas nitrogen, the chamber pressure is ...

Embodiment 2

[0063] (1) First, use degreaser, acetone and anhydrous ethanol to clean the titanium alloy substrate in sequence, put the cleaned and dried titanium alloy substrate into the vacuum chamber, and first pass argon gas into the vacuum chamber for 35.0sccm , set the current of the linear anode ion source to 0.2A, the chamber pressure to 0.2Pa, and use ionized argon ions to etch the substrate for 30 minutes; then use arc ion plating technology to deposit the Ti binding layer, the target is Ti target, and the substrate is negative The bias voltage is -70V, the arc current is 70A, the Ar gas pressure is 6.0Pa, and the deposition thickness is 2.0μm;

[0064] (2) Then adopt the arc ion plating technology to deposit the TiN transition layer, feed the reaction gas nitrogen, the chamber pressure is 6.0Pa, the arc current is 70A, the bias voltage is -70V, and the thickness is 4.0μm;

[0065] (3) The TiAlN layer is deposited by arc ion plating technology, and the reaction gas nitrogen is int...

Embodiment 3

[0069](1) First, use degreaser, acetone and anhydrous ethanol to clean the titanium alloy substrate in sequence, put the cleaned and dried titanium alloy substrate into the vacuum chamber, and first pass argon gas into the vacuum chamber for 35.0sccm , set the current of the linear anode ion source to 0.2A, the chamber pressure to 0.2Pa, and use ionized argon ions to etch the substrate for 30min; then use arc ion plating technology to deposit the Ti binding layer, the target is Ti target, and the substrate is negative The bias voltage is -70V, the arc current is 70A, the Ar gas pressure is 6.0Pa, and the deposition thickness is 2.0μm;

[0070] (2) Then adopt the arc ion plating technology to deposit the TiN transition layer, feed the reaction gas nitrogen, the chamber pressure is 6.0Pa, the arc current is 70A, the bias voltage is -70V, and the thickness is 4.0μm;

[0071] (3) The TiAlN layer is deposited by arc ion plating technology, and the reaction gas nitrogen is introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com