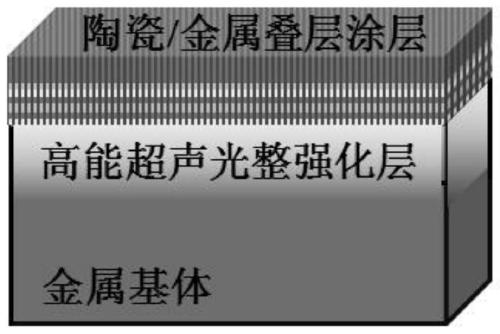

Composite surface reinforcement method capable of considering erosion resistance and anti-fatigue property of metal material

A metal material and composite surface technology, applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems of easy cracks, high hardness and poor toughness of the wear-resistant protective film layer, and achieve increased bonding The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

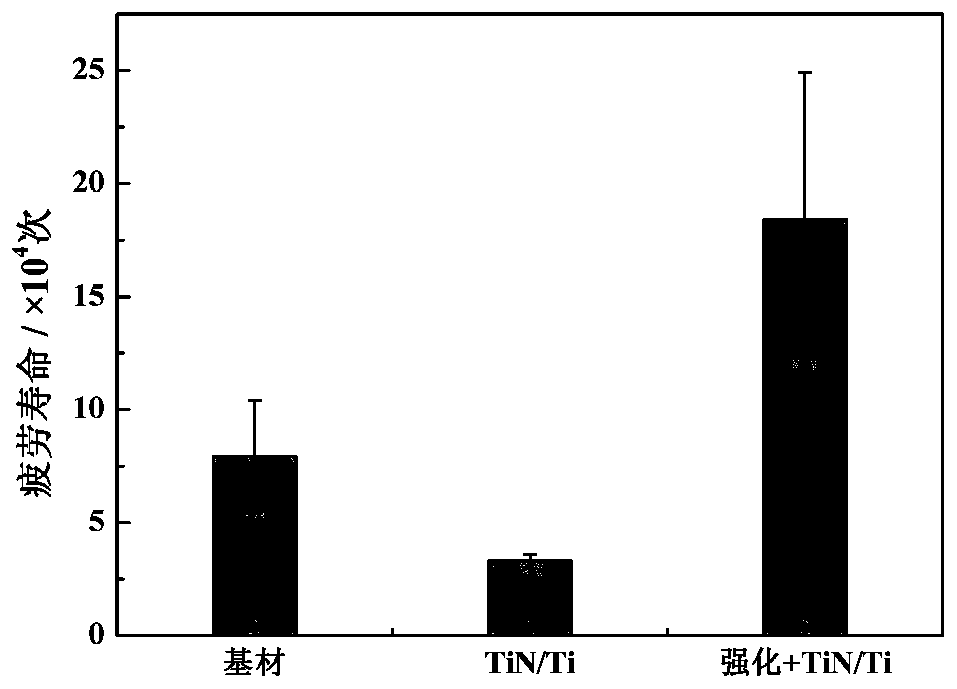

Embodiment 1

[0028] The TC4 titanium alloy was processed into Φ30×4mm discs and rotating bending fatigue specimens (according to the standard "HB5152-96 metal room temperature rotating bending fatigue test method"), and the plasma-enhanced deposition technology was used to prepare ceramics on the surface of the titanium alloy. Before the metal composite film layer, the surface is strengthened and pretreated with the help of high-energy ultrasonic finishing and strengthening technology, and the strengthened titanium alloy sample is ultrasonically cleaned and dried for use. The titanium alloy high-energy ultrasonic finishing and strengthening treatment steps are as follows: fix the fatigue sample on the CNC lathe with a triangular clamp and thimble, adjust the axis position of the fatigue sample and the ultrasonic strengthening tool ball head to ensure that the center of the ball head is level with the axis of the fatigue sample , Then set the lathe axial feed (0.2mm / r), speed (130r / min) and s...

Embodiment 2

[0033] The 17-4PH stainless steel was processed into Φ30×4mm discs and rotating bending fatigue specimens (according to the standard "HB5152-96 metal room temperature rotating bending fatigue test method"), and plasma-enhanced deposition technology was used on the surface of 17-4PH steel Before preparing the ceramic / metal composite film layer, the surface is strengthened and pretreated with the help of high-energy ultrasonic finishing and strengthening technology, and the strengthened stainless steel sample is ultrasonically cleaned and dried for use. The stainless steel high-energy ultrasonic finishing and strengthening treatment steps are as follows: fix the fatigue sample on the CNC lathe with a triangular clamp and thimble, adjust the axis position of the fatigue sample and the ultrasonic strengthening tool ball head to ensure that the center of the ball head is level with the axis of the fatigue sample Then set the lathe axial feed (0.15mm / r), speed (140r / min) and static pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com