Erosion resistant cermet linings for oil & gas exploration, refining and petrochemical processing applications

a technology of cermet and petrochemical, applied in the field of cermet materials, can solve the problems of protecting the walls of the refinery process vessel, and the internals of the vessel, and the internals of the vessel, and the internals are exposed to aggressive fluids containing hard, and are subject to both erosion and corrosion, and achieve excellent stability, excellent erosion resistance to sand, and outstanding thermal expansion compatibility to various substrate metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Illustrative Example 1

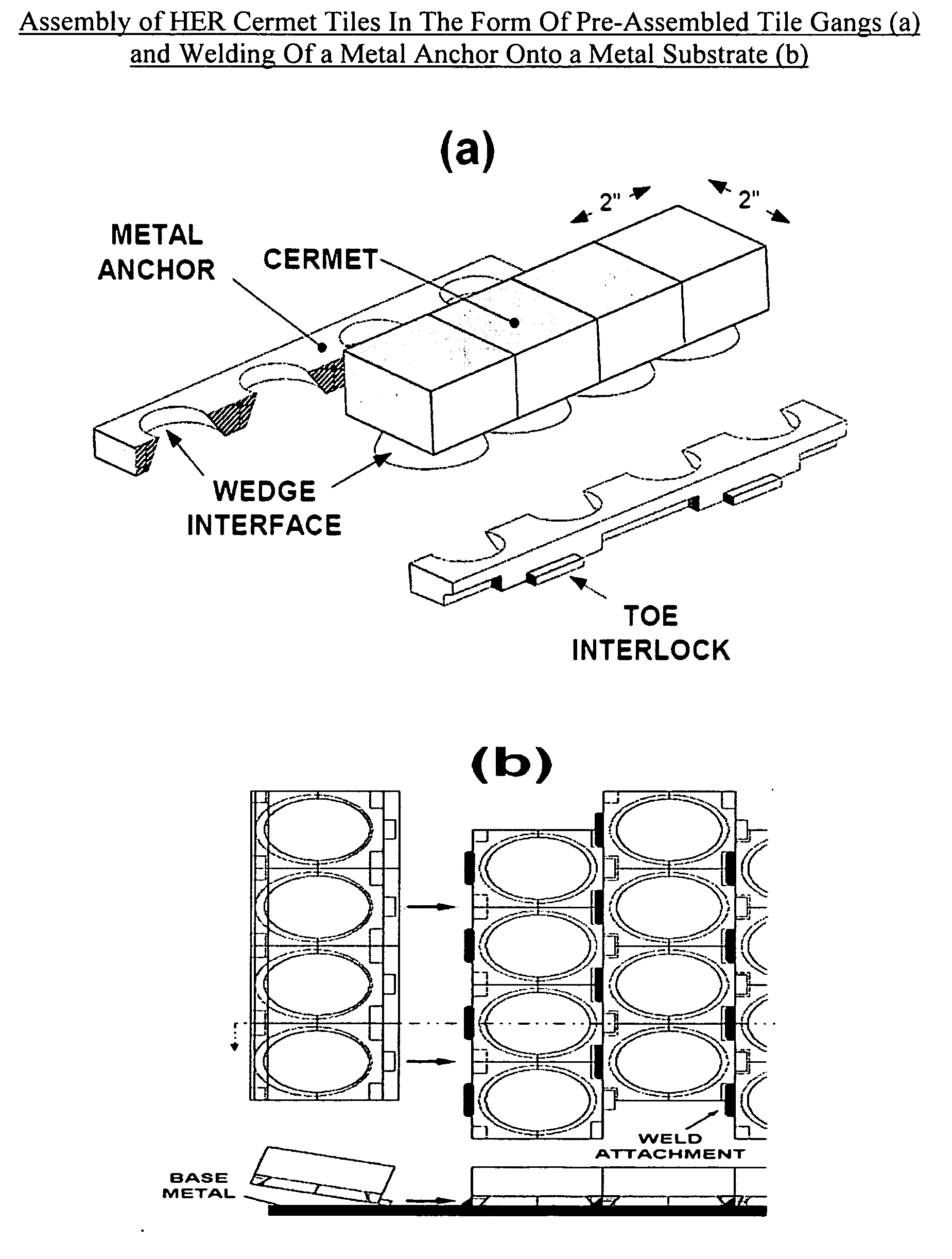

[0078]The TiB2 in stainless steel binder cermet of the present invention was tested experimentally as a liner in an actual cyclone drum or cylinder of an FCCU unit of a refinery. The liner was formed from tiles created by powder metallurgy processing attached via fusion welding of metal anchor to the inside wall of the cyclone. To provide a direct comparison with the prior art materials, sections of the cyclone liner or drum were also provided with Si3N4 tiles, SiC tiles, alumina tiles of 1½″ square and alumina tiles of 4½″ square. The cyclone drum was exposed to 26 thermal cycles with heat / cool rates from. The cyclone drum of FIG. 6 was exposed to 26 thermal cycles with heating / cooling rate severity of up to 500° F. / hr (100° F. / hour to 500° F. / hour) in FCCU catalyst. The prior art Si3N4 and SiC lining tiles (FIG. 6(a)), and the prior art alumina lining tiles (FIG. 6(b) and (c)) all failed as exhibited by cracks in and missing tiles after exposure to 26 thermal...

example 2

Illustrative Example 2

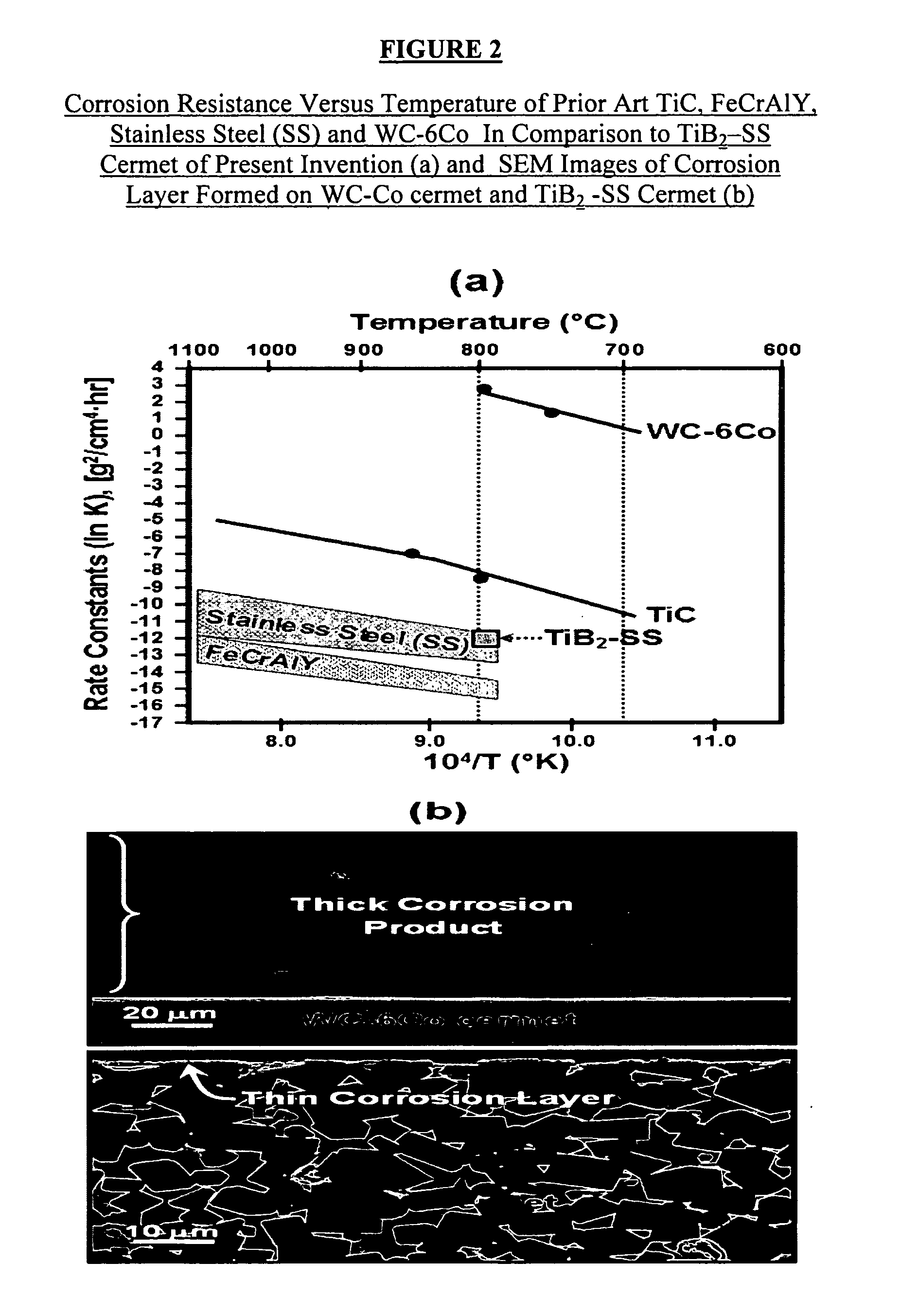

[0079]The HER cermet linings and inserts of the present invention are suitable for many areas in refining and petrochemical processing units with temperatures in excess of 600° F. (316° C.) where FIG. 7 depicts a plot of HEAT determined erosion resistance (HEAT erosion resistance index) versus K1c fracture toughness (MPa-m1 / 2) of a wide range of material candidates for high temperature linings using measured or published fracture toughness data for three point bending at room temperature. The plot exhibits that prior art materials (hard alloys and WC, refractories, and ceramics) follow the trend line showing the inverse relationship between fracture toughness and erosion resistance. That is a material with a high hot erosion resistance has poor fracture toughness and vice-versa. By comparison, data for the HER cermet linings of the present invention do not fall along the trend line, but are within a different regime considerably above the trend line (see “HER c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com