Comprehensive performance evaluation method for surfacing layer of sealing surface of valve seat

A technology of comprehensive performance evaluation and surfacing layer, applied in the field of valve seat sealing surface, it can solve the problem that there is no professional comprehensive evaluation method for the valve seat sealing surface, and achieve the effect of reaching the service life standard, ensuring safe and reliable use, and ensuring comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

[0015] 1. A comprehensive performance evaluation method for the surfacing layer of the valve seat sealing surface

[0016] The prior art methods can only evaluate the performance of a certain aspect of the surfacing layer on the sealing surface of the valve seat from a simple evaluation of a single dimension, and avoid some performance evaluations that are extremely important for the surfacing layer on the sealing surface of the valve seat, such as , high-temperature impact resistance and high-temperature erosion resistance. In the prior art, there are almost no tests designed to evaluate and analyze these two aspects. However, it is possible to evaluate the performance of the surfacing layer on the sealing surface of the valve seat from multiple dimensions. The innovation of the present invention lies.

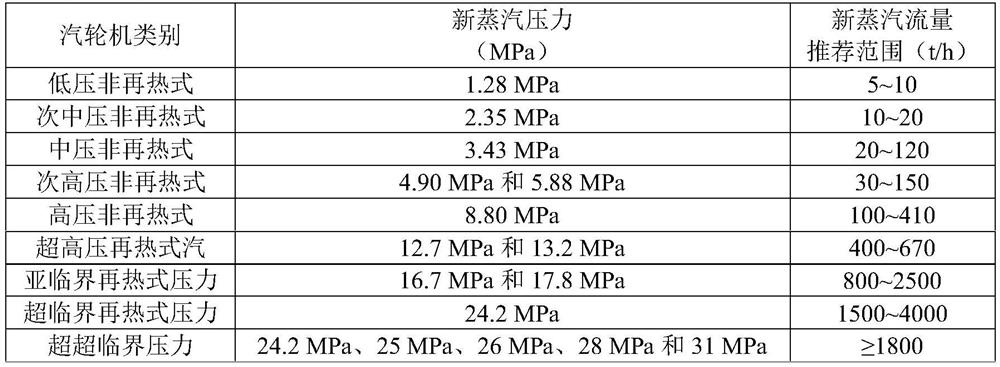

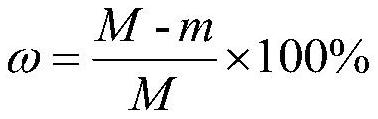

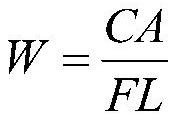

[0017] (1) According to the purpose of the valve seat, determine its working t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com