Terahertz light source chip and manufacturing method thereof, terahertz light source device and manufacturing method thereof, and terahertz light source module and manufacturing method thereof

A terahertz and light source technology, applied in semiconductor devices, solid-state lasers, electrical components, etc., can solve problems such as large loss, unfavorable conversion efficiency, and low quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

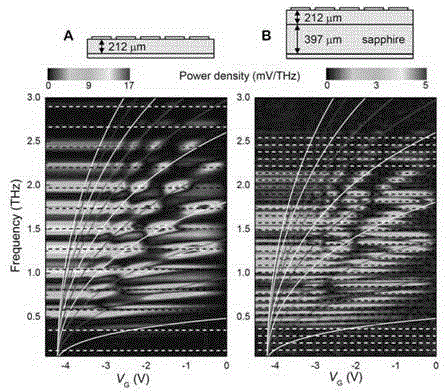

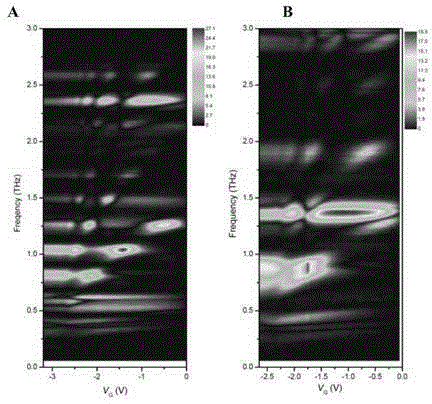

[0147] This embodiment provides a terahertz light source chip (also referred to as a first terahertz light source chip in this embodiment), a corresponding light source device and assembly, and a manufacturing method thereof. figure 1 It is a schematic diagram of the principle of the terahertz light source chip according to this embodiment. figure 2 It is the dispersion relation diagram of the plasma wave and the dispersion relation diagram of the cavity mode of the terahertz resonant cavity. Figure 3A It is a top view of the structure of the terahertz light source of this embodiment, Figure 3B for Figure 3A The cross-sectional view of the terahertz light source chip and the schematic diagram of the current drive.

[0148] like figure 1 As shown, the terahertz light source chip includes: a two-dimensional electron gas mesa 1; an electrode (not shown) for exciting a plasma wave 6 formed on the two-dimensional electron gas mesa 1; a terahertz resonant cavity 3, the The t...

Embodiment approach 2

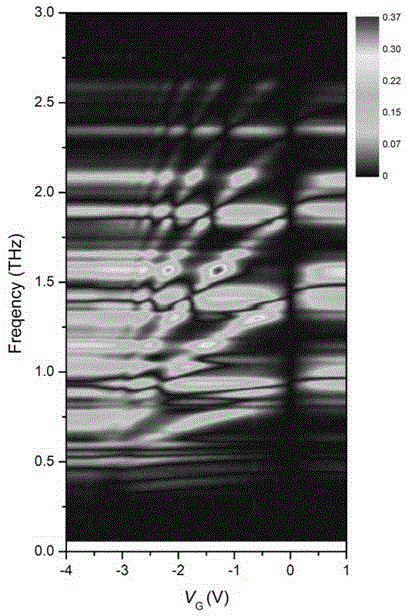

[0214] This embodiment is further improved on the basis of Embodiment 1, and another chip (also referred to as a second terahertz light source chip in this embodiment), corresponding light source devices and components, and its manufacturing method are provided to provide The escape loss of terahertz light is reduced, thereby further improving the quality factor of the terahertz resonant cavity, enhancing the coupling strength between the cavity mode of the resonant cavity and the plasma wave mode, and improving the conversion efficiency.

[0215] Image 6 It is a schematic structural diagram of the terahertz light source chip in this embodiment. Figure 7 To show one form of the plasmon wave mode and the terahertz resonator mode generated under the grating-resonator coupling.

[0216] Such as Image 6 As shown, the terahertz light source chip of this embodiment includes: a two-dimensional electron gas mesa 1; electrodes (such as source S and drain D; source and drain electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com