Chloridization corrosion resistant double-layer structure alloy coating for heating surface of garbage incinerator and preparation method

A waste incinerator, double-layer structure technology, applied in metal material coating process, coating, fusion spraying, etc., can solve problems such as tube explosion, thinning, high temperature chlorine corrosion and solid particle erosion of tube wall, etc. Achieve the effects of prolonging life, simple operation, and improving resistance to chlorine corrosion and solid particle erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

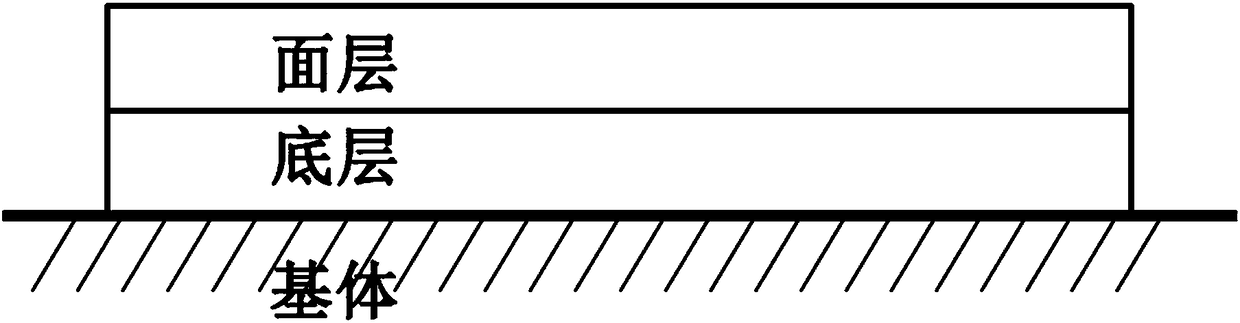

Image

Examples

Embodiment 1

[0027] In this embodiment, a method for preparing an anti-chlorine corrosion double-layer structure alloy coating on the heating surface of a garbage incinerator comprises the following steps:

[0028] (1) Dry the powder material of the chlorine corrosion-resistant bottom layer and the powder material of the solid particle erosion-resistant surface layer at low temperature.

[0029] (2) Pre-treat the surface of the substrate on the heating surface of the waste incinerator, remove the surface oxide film and dirt, and then perform sandblasting on the substrate.

[0030] (3) The chlorine-resistant corrosion-resistant bottom layer in the double-layer structure coating was prepared by active combustion high-velocity gas spraying (HVAF). The spraying distance is 315mm, the thickness of the prepared chlorine corrosion-resistant bottom layer is 0.3mm, the porosity is ≤1%, and the bonding strength is ≥65MPa.

[0031] (4) The supersonic flame spraying process is used to prepare the sol...

Embodiment 2

[0034] In this embodiment, a method for preparing an anti-chlorine corrosion double-layer structure alloy coating on the heating surface of a garbage incinerator comprises the following steps:

[0035] (1) Dry the powder material of the chlorine corrosion-resistant bottom layer and the powder material of the solid particle erosion-resistant surface layer at low temperature.

[0036] (2) Pre-treat the surface of the substrate on the heating surface of the waste incinerator, remove the surface oxide film and dirt, and then perform sandblasting on the substrate.

[0037] (3) The chlorine-resistant corrosion-resistant bottom layer in the double-layer structure coating was prepared by the active combustion high-velocity gas spraying (HVAF) process. The spraying process parameters were: air pressure was 0.65MPa, propane pressure was 0.6MPa, and nitrogen flow rate was 60L / min. The spraying distance is 325mm, the thickness of the prepared chlorine corrosion-resistant bottom layer is 0...

Embodiment 3

[0041] In this embodiment, a method for preparing an anti-chlorine corrosion double-layer structure alloy coating on the heating surface of a garbage incinerator comprises the following steps:

[0042] (1) Low-temperature drying is carried out to the above-mentioned chlorine corrosion-resistant bottom layer powder material and solid particle erosion-resistant surface layer powder material.

[0043] (2) Pre-treat the surface of the substrate on the heating surface of the waste incinerator to remove the surface oxide film and dirt, and then perform sandblasting on the substrate.

[0044] (3) The chlorine corrosion-resistant bottom layer in the double-layer structure coating was prepared by the active combustion high-velocity gas spraying (HVAF) process. The spraying process parameters were: air pressure was 0.7MPa, propane pressure was 0.6MPa, and nitrogen flow rate was 65L / min. The spraying distance is 335mm, the thickness of the prepared chlorine corrosion-resistant bottom lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com