Method for reducing solid particle erosion to supercritical steam turbine

A technology of solid particles and steam turbines, applied in the direction of solid separation, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of reducing the safety and economy of unit operation, shortening the operating life of the unit, and metal oxide shedding, etc., to achieve Improved safety and economy, simple structure, and the effect of promoting shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

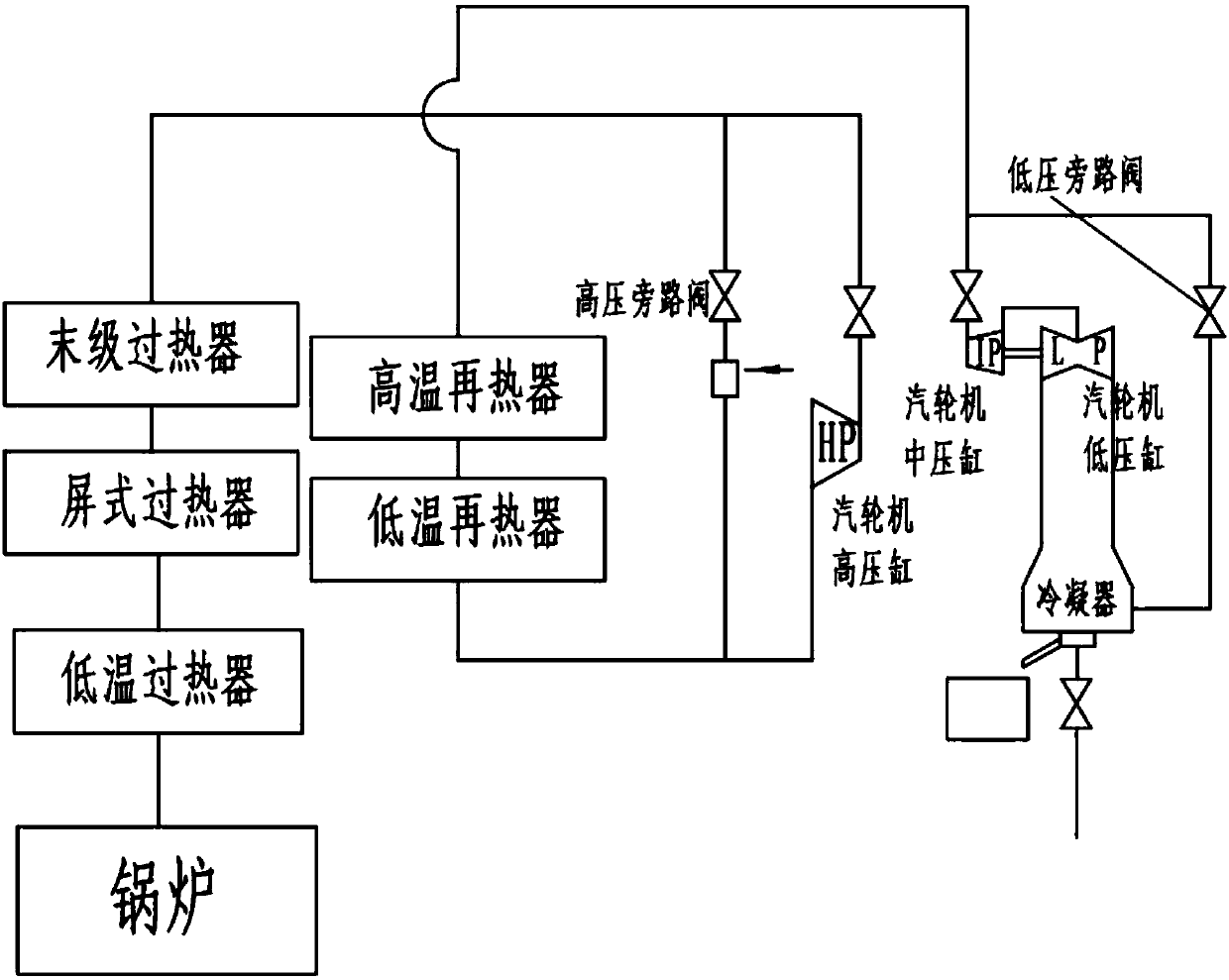

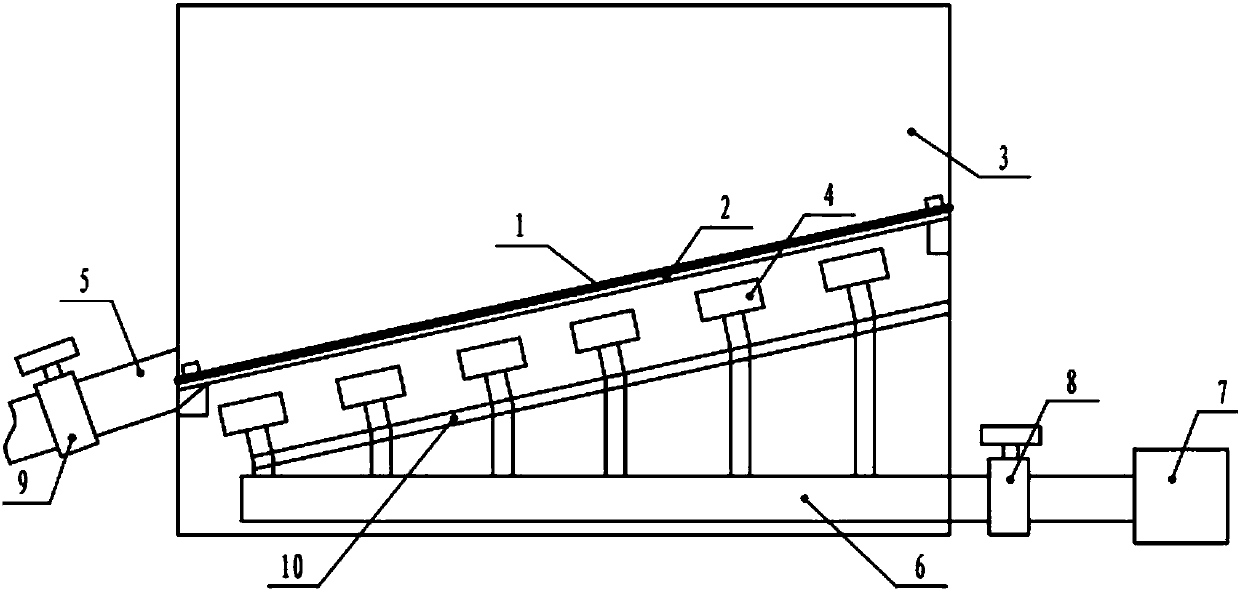

[0025] Embodiment 1: as Figure 1-Figure 4 Shown, a kind of method for reducing supercritical steam turbine solid particle erosion, this method comprises the following steps:

[0026] (1) During the start-up process of the unit with sliding parameters, the boiler evaporation is controlled to be 10% of the maximum continuous evaporation (MCR), the steam pressure is maintained at 2.5Mpa, and the steam has a superheat of not less than 50°C;

[0027] (2) Close the high and medium pressure main steam valves and high and medium pressure regulating steam valves of the steam turbine, open the high pressure bypass valve and low pressure bypass valve of the steam turbine at the set opening, and ensure that the steam pressure in front of the turbine is maintained at 2.5MPa;

[0028] (3) Under this working condition, the steam pipeline of the supercritical boiler is purged under pressure to promote the falling off of the metal oxide attached to the inner wall of the tube bundle on the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com