Device for realizing erosion resistance test

A technology of anti-erosion and performance, which is applied in the field of devices that realize the test of anti-erosion performance, can solve the problem of difficult to accurately and quantitatively test the anti-erosion performance of powder feeding materials, and achieve the effect of quantitative evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

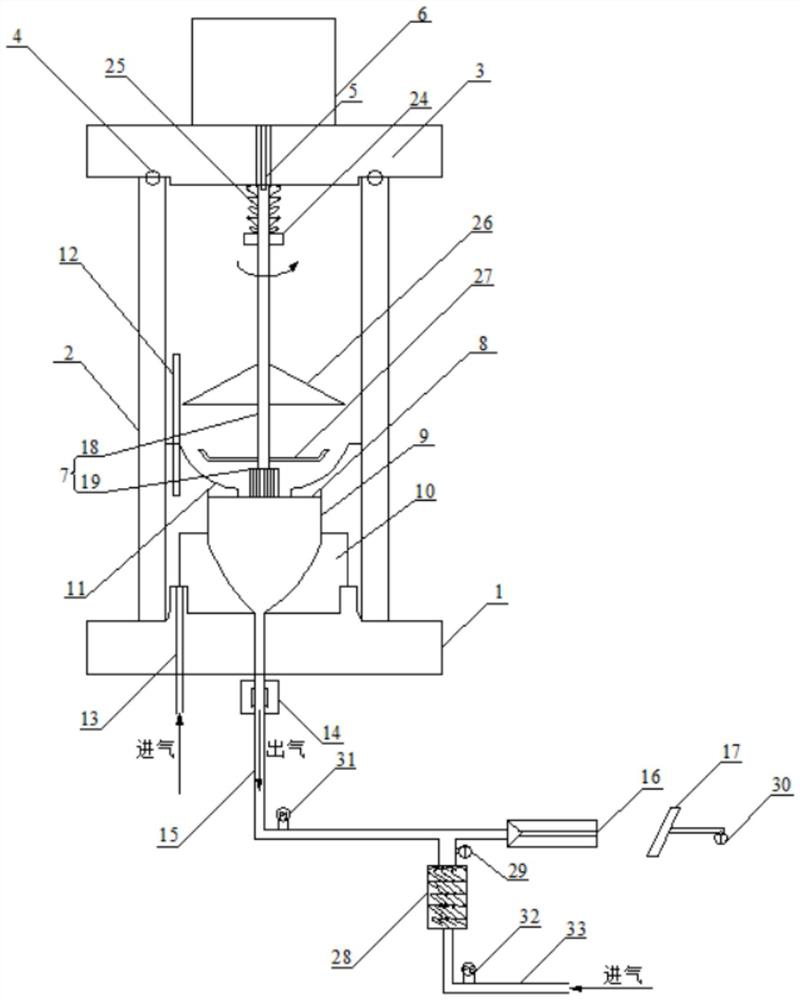

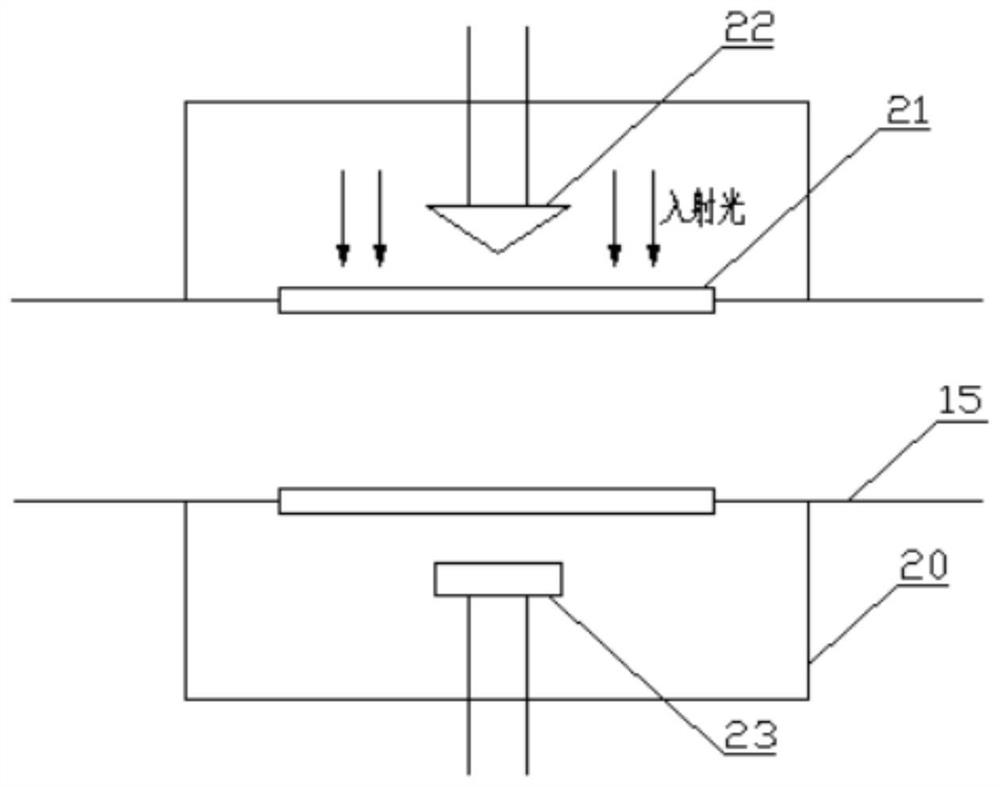

[0042] A kind of device that realizes anti-erosion performance test provided by the present invention, such as figure 1 As shown, it includes: a support 1, a cylindrical silo body 2 on the pedestal 1, a flange 3 on the silo body 2, a sealing ring 4 between the silo body 2 and the flange 3, and runs through the flange 3 Coupling 5, stepper motor 6 on flange 3, agitator 7, scraper 8, funnel 9, vibrator 10, powder storage 11 and balance tube 12 in bin 2, the first feeder Air pipe 13, powder delivery amount detector 14, powder outlet pipe 15, the spray gun 16 that communicates with the end of powder outlet pipe 15, and the movable sample stage 17 that is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com