Solid particle pre-whirl mixing pneumatic acceleration device and method

A technology of solid particles and acceleration device, applied in the direction of liquid injection device, injection device, etc., can solve the problem of reducing the accuracy of material erosion test, and achieve the effect of improving consistency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

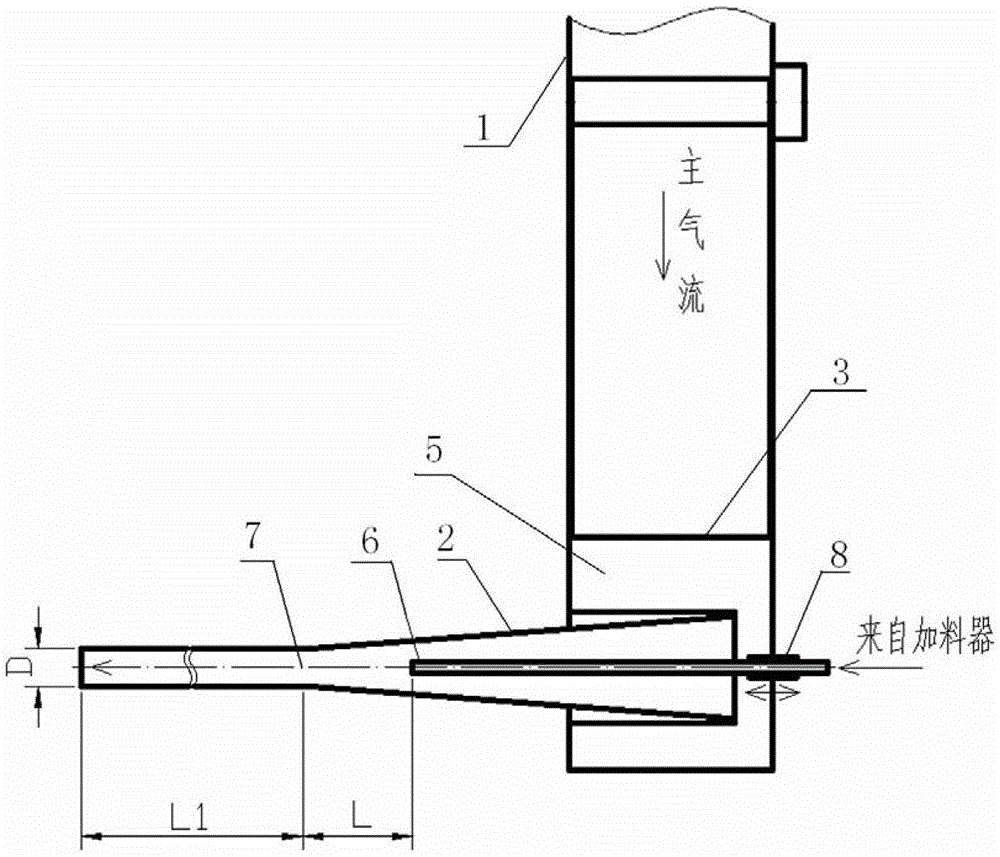

[0035] see image 3 , Figure 4 , a solid particle pre-swirling mixing pneumatic acceleration device, including an air inlet pipe 1 and an acceleration nozzle 2 connected to the air inlet pipe 1, the connection between the acceleration nozzle 2 and the air inlet pipe 1 is provided with a gas flow that enters the acceleration nozzle 2 The airflow pre-swirling device that generates the swirling flow, the airflow pre-swirling device is the deflector 3 arranged in the intake pipe 1, the deflector 3 and the wall of the intake pipe 1 are formed so that the airflow flows into the inlet of the acceleration nozzle 2 along the tangential direction The wedge-shaped flow channel, the deflector 3 can be rotated, and the side wall of the intake pipe 1 is inwardly recessed to form a groove. It is connected to the air outlet at the bottom of the groove. The function of the ring cavity is to stabilize the air flow on the one hand and assist the generation of swirling flow on the other hand. T...

Embodiment 2

[0039] see Figure 5 , Image 6 , a solid particle pre-swirling mixing pneumatic acceleration device, including an air inlet pipe 1 and an acceleration nozzle 2 connected to the air inlet pipe 1, the connection between the acceleration nozzle 2 and the air inlet pipe 1 is provided with a gas flow that enters the acceleration nozzle 2 An airflow pre-swirling device for generating swirling flow, the airflow pre-swirling device is a swirler 4 arranged at the inlet of the acceleration nozzle 2, and the swirler 4 includes 5 (preferably 3 to 8) guide vanes, the exhaust angle is 60° (the value range is 35°~80°), one side of the inlet pipe 1 is sunken inward to form a groove, and the groove divides the inside of the inlet pipe into a ring cavity 5, and the inlet of the acceleration nozzle 2 is connected with the opening It is connected to the air outlet at the bottom of the groove. The function of the ring cavity is to stabilize the air flow on the one hand and assist the generation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com