Oil-dispersed sodium hyaluronate and preparation method and application of same

A technology of sodium hyaluronate and oil dispersion, which is applied in body powder, pharmaceutical formulations, cosmetic preparations, etc., to achieve the effect of smooth skin feeling, not easy to gather and precipitate, and firmly lock water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (a) Take the HA ( M w =6,200 Da) micropowder 60.0g;

[0041] (b) Take 56.0g of castor bean oil, fully mix it with HA micropowder, homogenize it at 10000rpm for 3min, and preheat it to 90℃ in a water bath to get a suspension;

[0042] (c) Take 84.0g of hydrogenated castor oil, heat it to 90°C and melt it completely, stir and mix it with the preheated suspension in step (b) while it is still hot, and immediately homogenize at 10000rpm for 3 times, each time for 2min, with an interval of 20s . Finally, it is condensed and granulated to form milky white to light yellow solid particles.

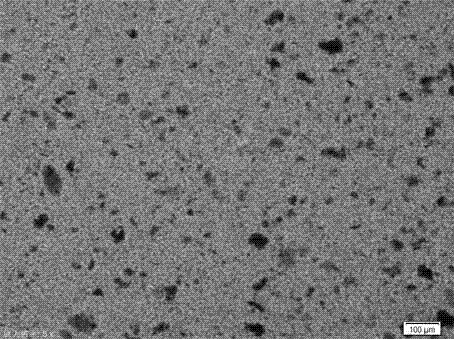

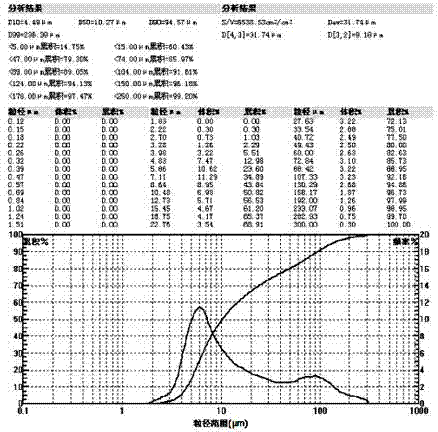

[0043] The HA content determined by the carbazole method was 28.5%. The smear was observed under an electron microscope, and the HA micropowder in the oil phase presented irregular agglomerates, slightly swollen, and uniformly dispersed (see figure 1 ), the particle size analysis report shows that the final average particle size of the HA micropowder in the oil dispersion is 10.27 μm ...

Embodiment 2

[0045] (a) Take the HA ( M w = 3,000,000 Da) Micropowder 2.0g;

[0046] (b) Take 160.0g of castor oil, mix well with HA micropowder, homogenize at 500rpm for 3min, and preheat to 90°C in a water bath to obtain a suspension;

[0047] (c) Take 38.0g of hydrogenated castor oil, heat it to 90°C and melt it completely, stir and mix it with the preheated suspension in step (b) while it is hot, and immediately homogenize at 3000rpm for 3 times, each time for 3min, with an interval of 30s , forming milky white to light yellow ointment after cooling.

[0048] The HA content determined by the carbazole method was 1.0%. The particle size analysis report showed that the final average particle size of the HA micropowder in the oil dispersion was 15.73 μm. Placed at 40°C for 24 hours, the dispersion was stable without precipitation and stratification.

Embodiment 3

[0050] (a) Take 100.0g of HA micropowder through 80-mesh sieve (of which M w = 400 Da for HA and M w = 150,000 Da of HA each 50.0g), mix well;

[0051] (b) Fully mix HA micropowder with 10.0g ethylhexyl palmitate dispersant to fully infiltrate HA, then mix with 40.0g olive oil and 20.0g polydimethylsiloxane (500 mm 2 / s) mix evenly, and homogenize at 8000rpm for 2min to obtain a suspension;

[0052] (c) Add 30.0 g of polydimethylsiloxane cross-linked polymer to the suspension, homogenize at 10,000 rpm for 3 times, each time for 2 minutes, with an interval of 30 seconds, to form a milky white to light yellow viscous liquid, and cool to obtain .

[0053] The HA content determined by the carbazole method was 49.8%. The particle size analysis report showed that the final average particle size of the HA micropowder in the oil dispersion was 17.02 μm. Placed at 40°C for 24 hours, the dispersion was stable without precipitation and stratification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com