Patents

Literature

73results about How to "Strong graininess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery cathode material, preparation method and lithium ion battery

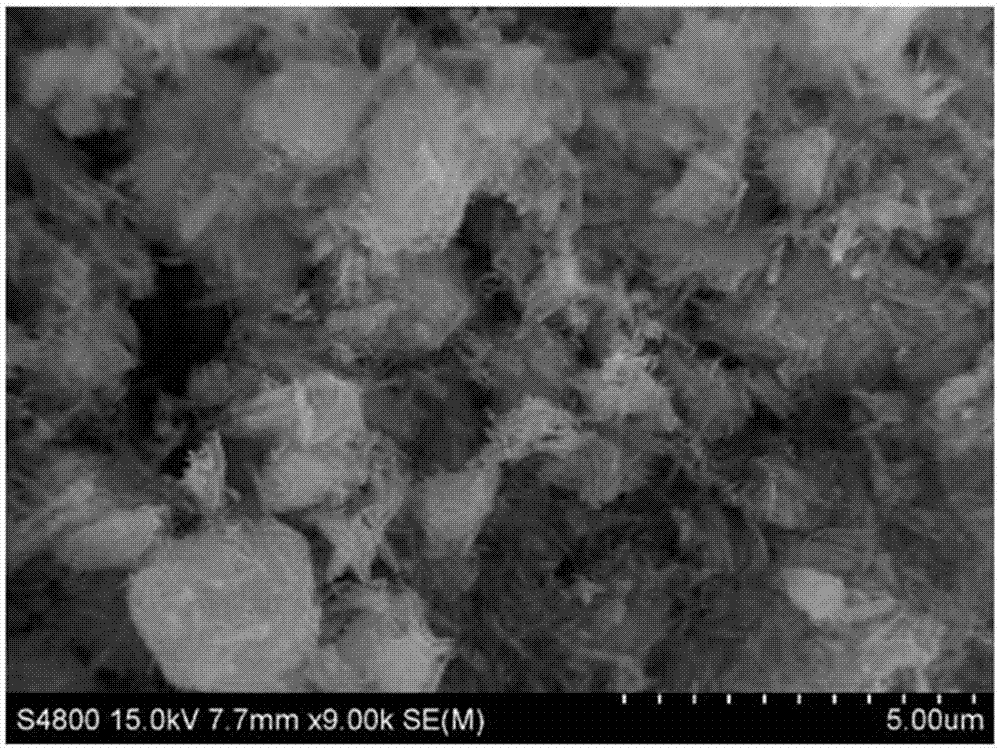

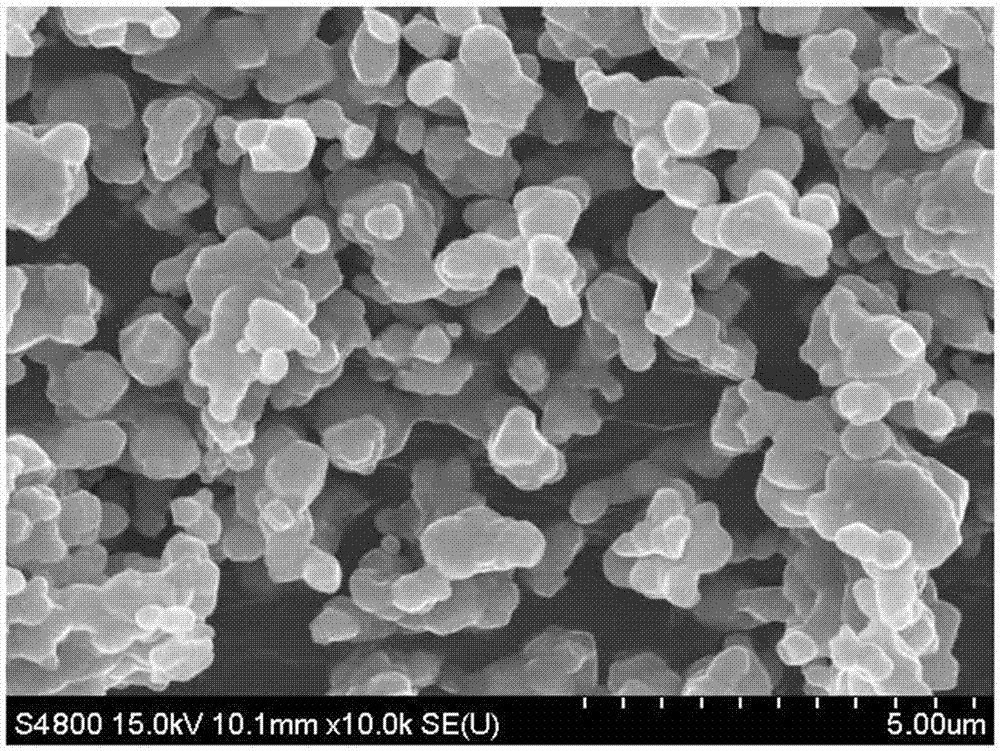

ActiveCN105449169AImprove storage effectEven distribution of elementsCell electrodesSecondary cellsPhysical chemistrySingle crystal

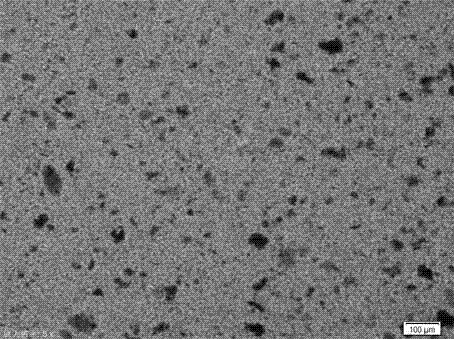

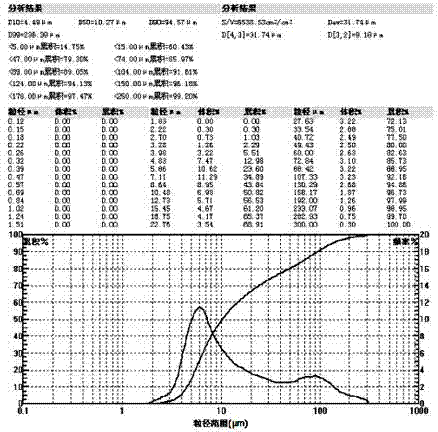

The invention provides a preparation method of a lithium ion battery cathode material. The prepared lithium ion battery cathode material has good pseudo-single crystal form by utilizing pressure-boiling crystal at certain temperature. The preparation method is simple in technology and easy in control. The general formula of the lithium ion battery cathode material prepared by the preparation method is expressed as Li (NixCo1-x-yMny) O2, wherein x is more than or equal to 0.34 and is less than or equal to 0.68, y is more than or equal to 0.15 and is less than or equal to 0.31, x +y is more than 0 and is less than 1. The invention also provides a lithium ion battery containing the lithium ion battery cathode material.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

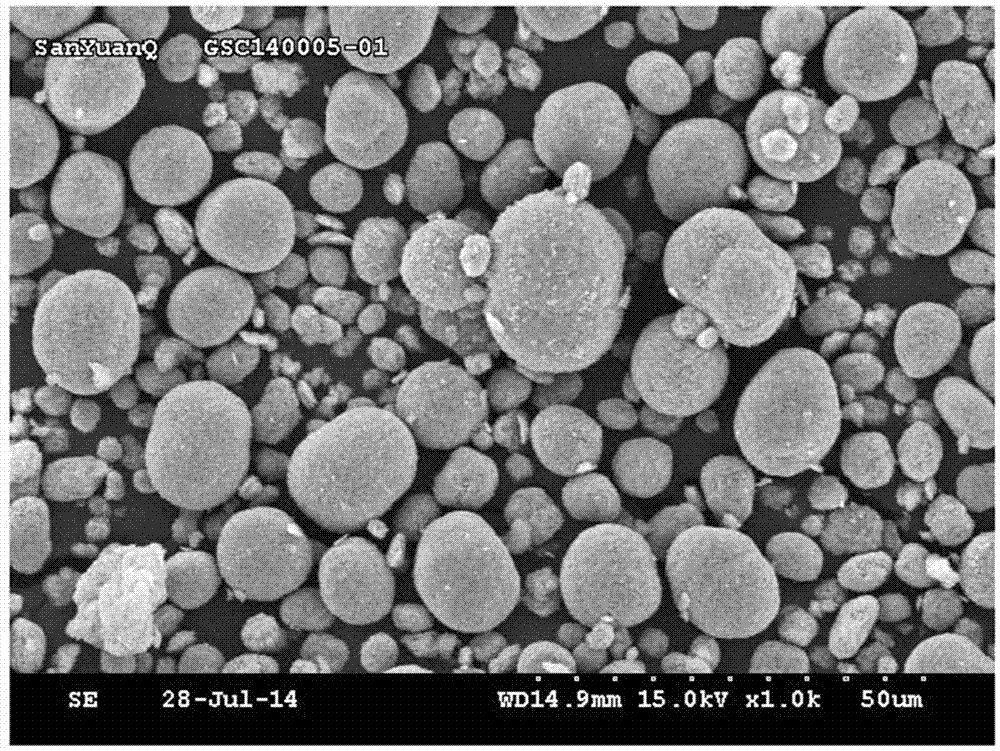

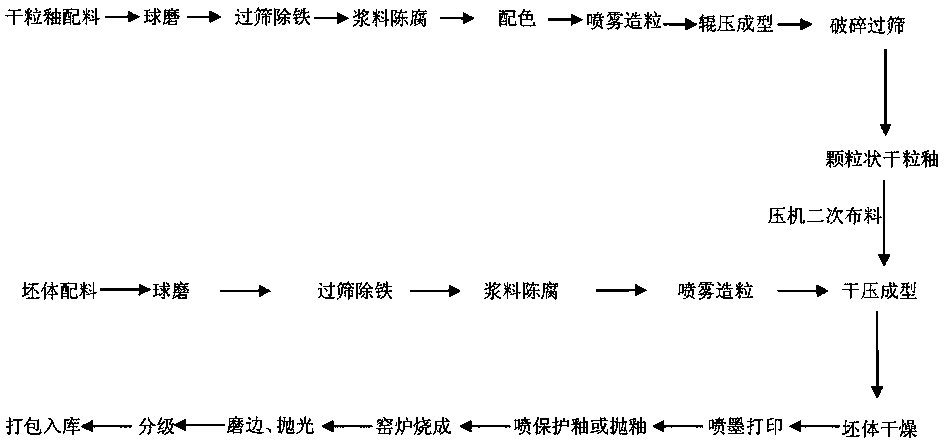

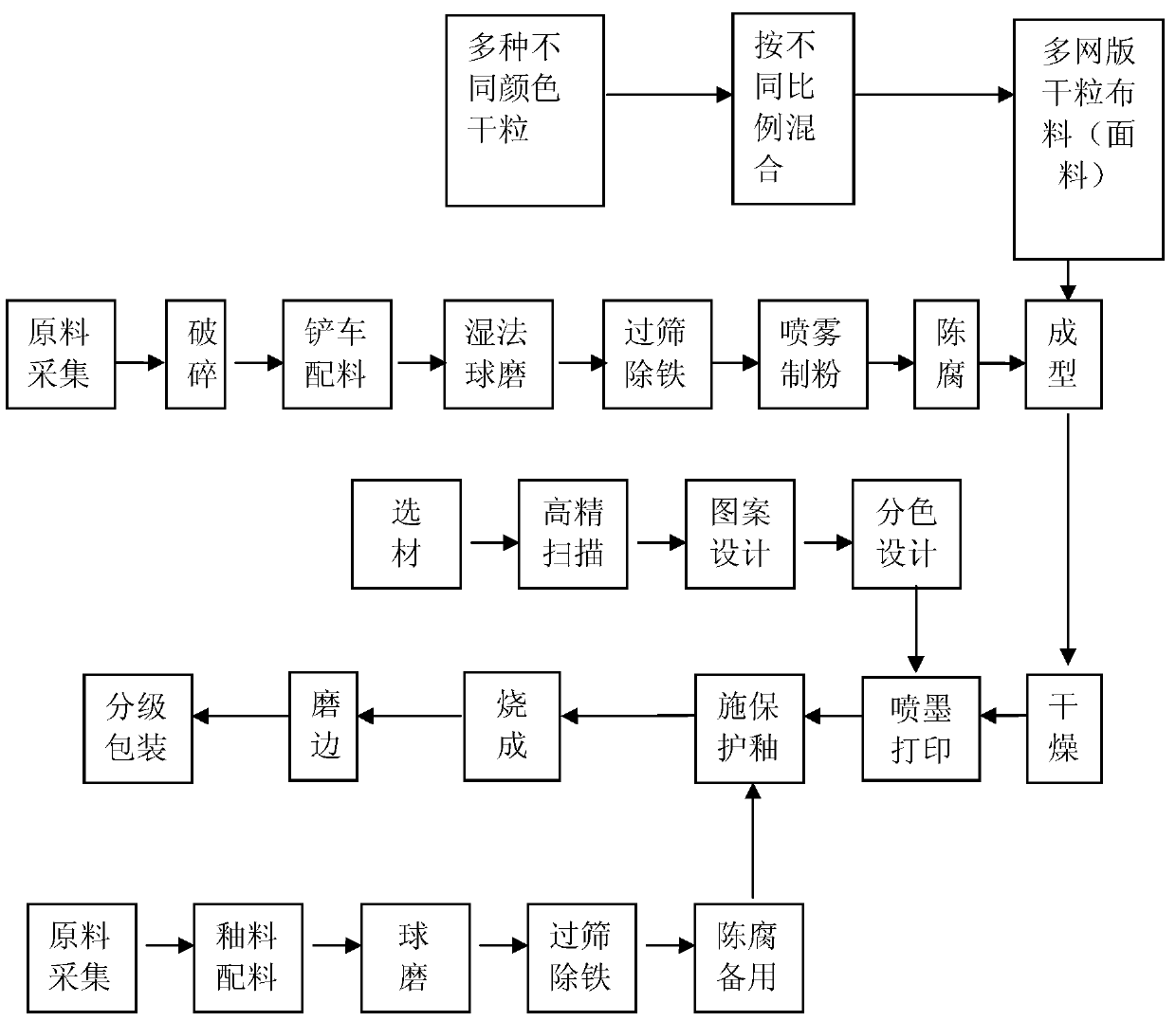

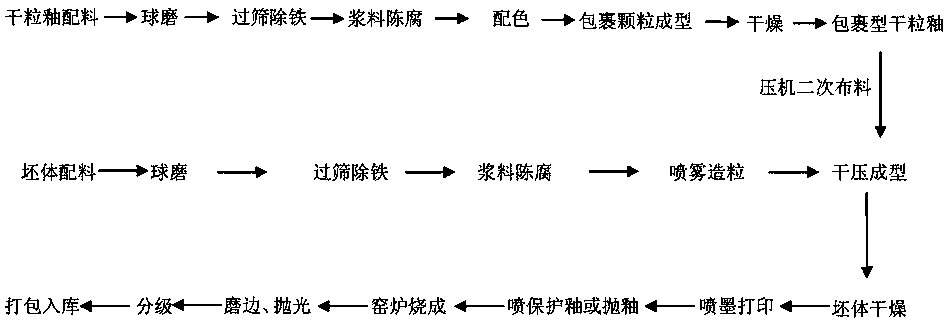

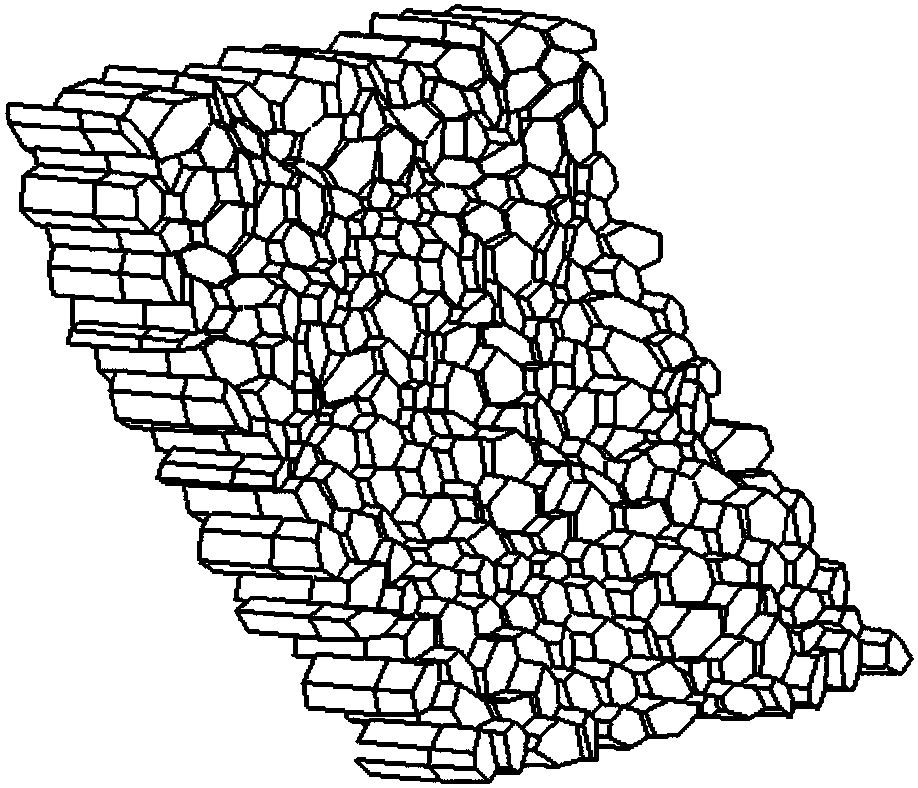

Granular dry grain glaze and granular dry grain glaze cloth imitation stone brick, and production methods thereof

The invention relates to a granular dry grain glaze and a granular dry grain glaze cloth imitation stone brick, and production methods thereof. The production method of the granular dry grain glaze comprises the following steps: squeezing glaze powder out of a blank cake; and breaking the blank cake to obtain the granular dry grain glaze. The granular dry grain glaze can be obtained through the simple method, and the granular dry grain glaze can be used in the production of ceramic bricks to obtain the imitation stone material product having accurate pattern, plentiful layers, natural texture,strong stereo perception and strong granular sensation.

Owner:MONALISA GRP CO LTD

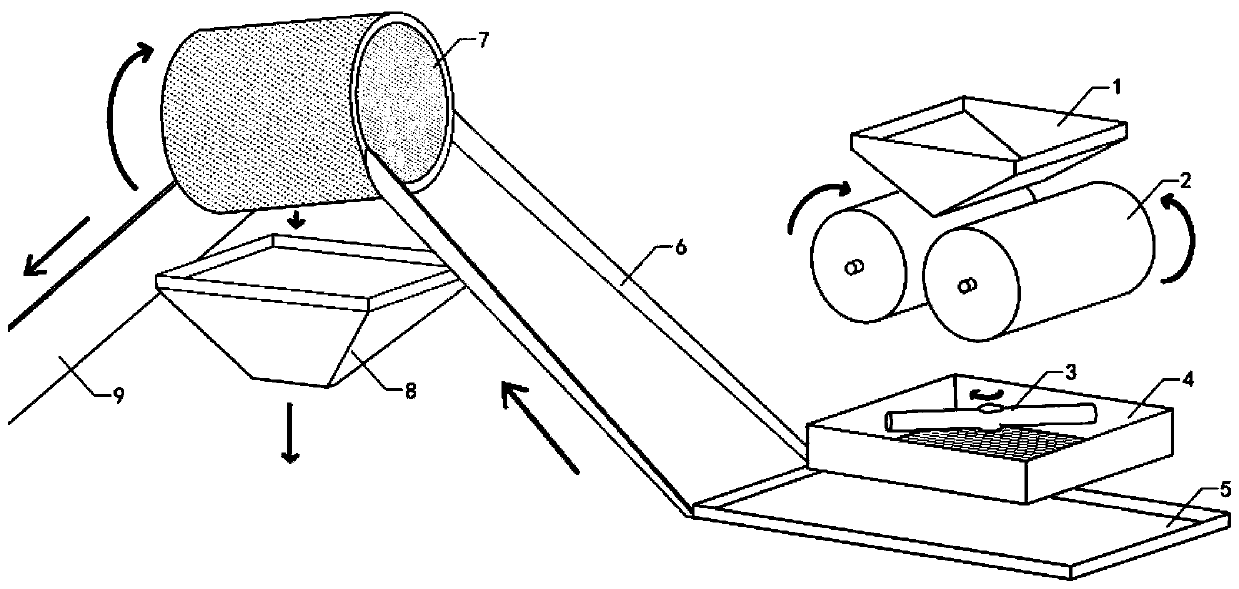

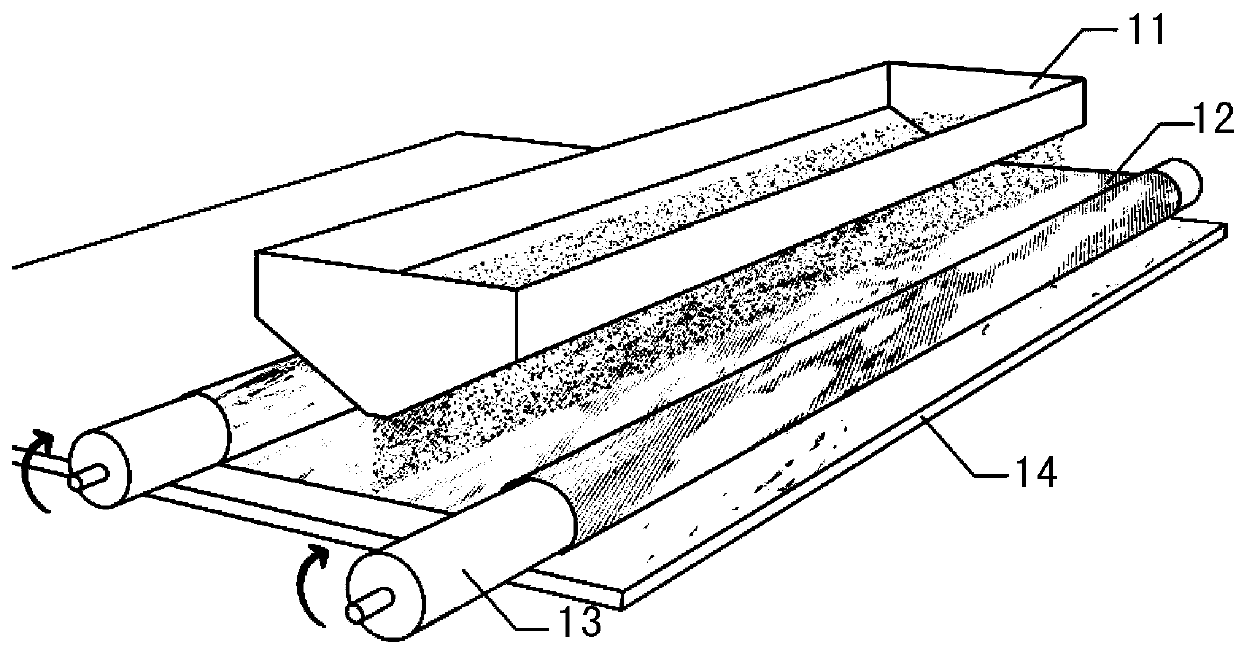

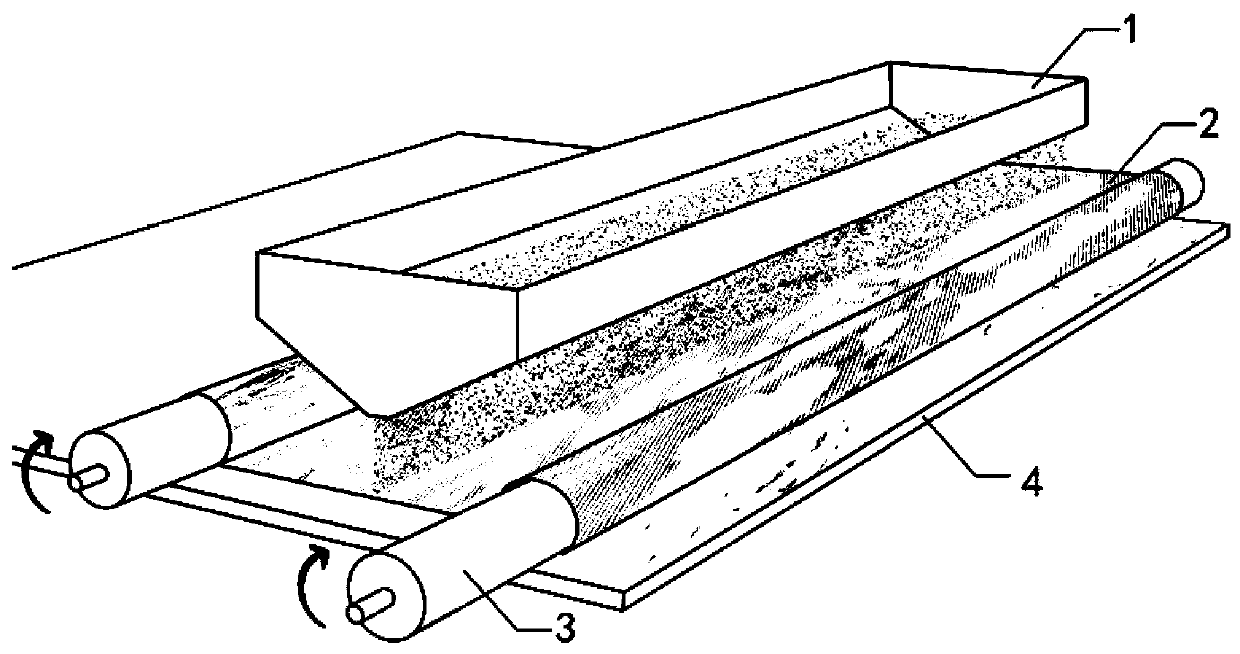

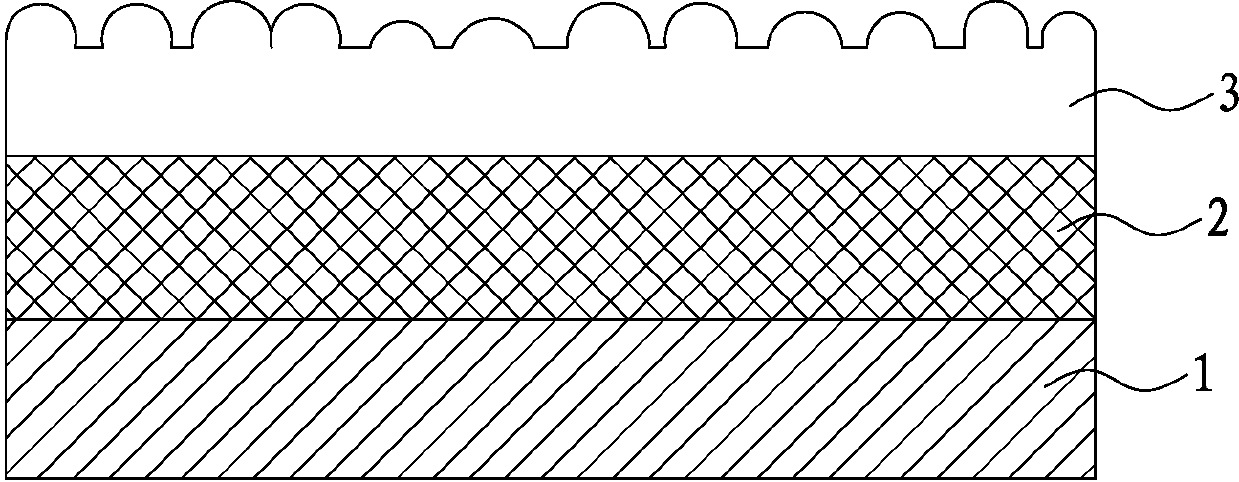

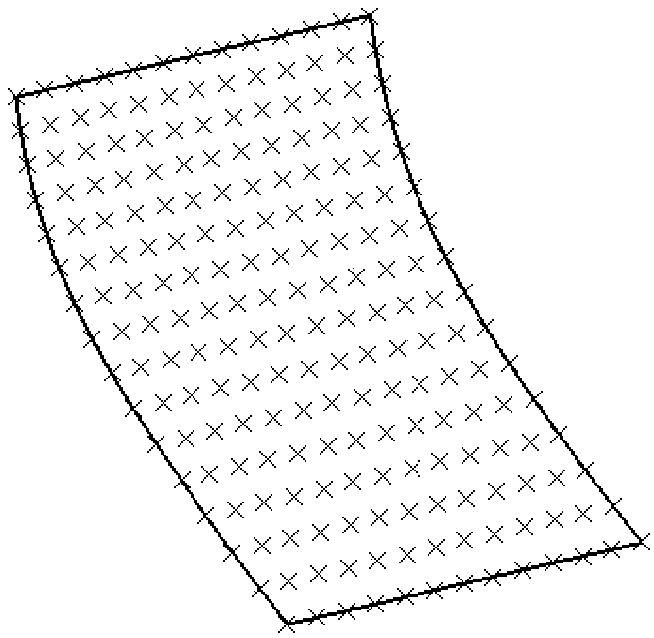

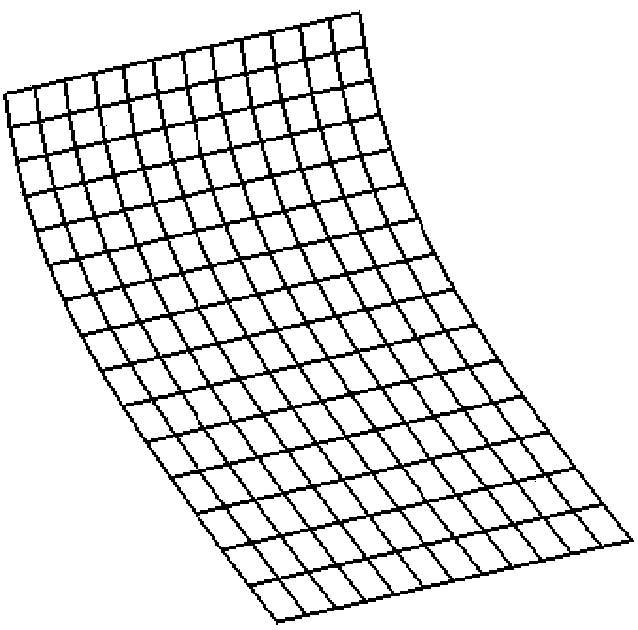

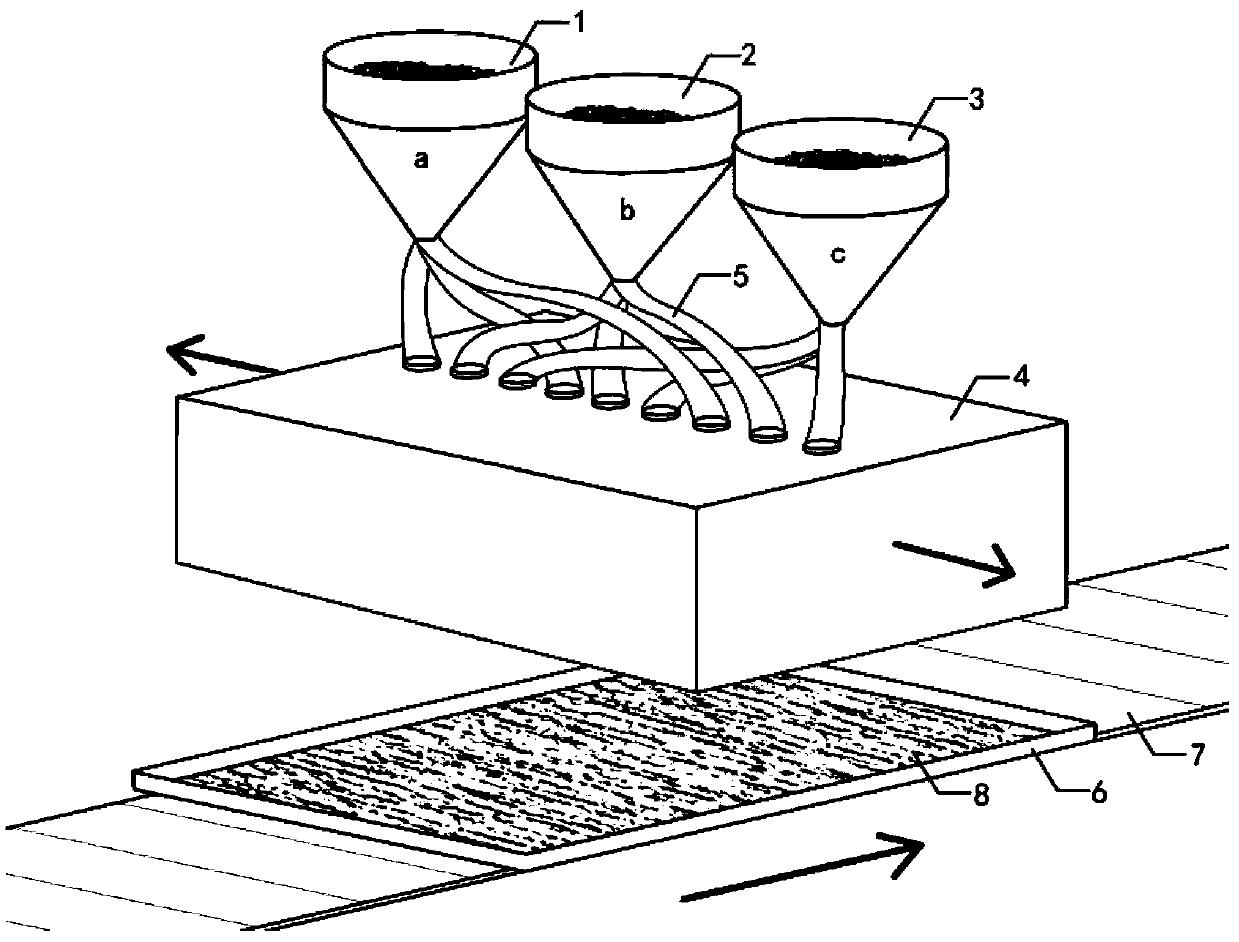

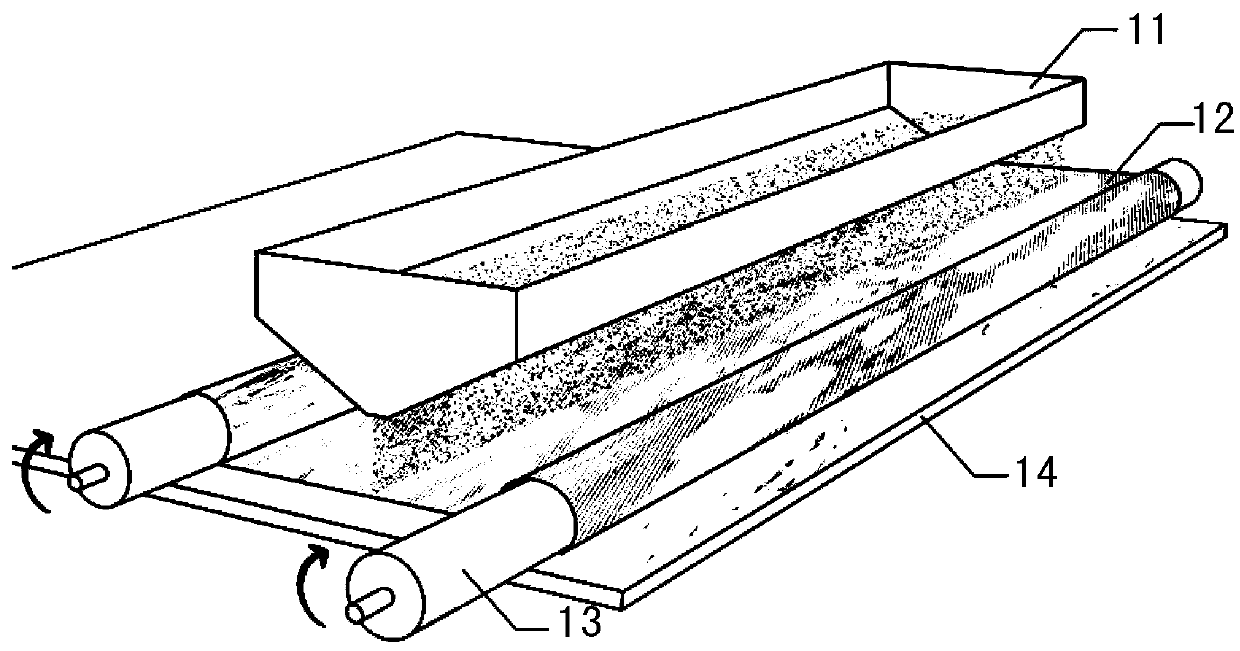

Dry grain glaze fabric stone imitating brick and preparing method thereof

ActiveCN107756608AThree-dimensionalRich layersNatural patternsCeramic shaping apparatusBrickMaterials science

The invention relates to a dry grain glaze fabric stone imitating brick and a preparing method thereof. The preparing method of the dry grain glaze fabric stone imitating brick includes the followingsteps that firstly, colored dry grain glaze is distributed on a blank in a layered manner according to a designed pattern; secondly, after glaze distributing is conducted, a raw brick is pressed; thirdly, after the raw brick is dried, an inkjet machine is used for jet printing of the design pattern; and fourthly, the obtained blank is fired. By means of the dry grain glaze fabric stone imitating brick and the preparing method thereof, a stone imitating effect that the pattern is changed randomly and is vivid and rich in layer, the texture is natural, and the third dimension and granular sensation are high can be achieved.

Owner:MONALISA GRP CO LTD

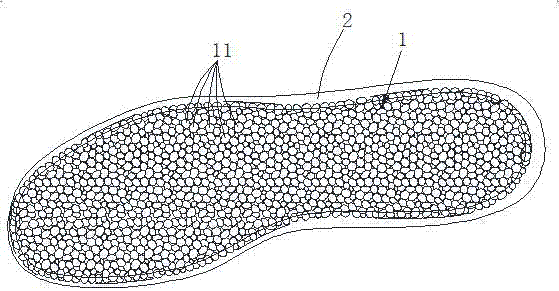

Production process of E-TPU (expanded thermoplastic polyurethane) shoe material

InactiveCN107353428APromote environmental protectionReduce usage requirementsSolesDevices for pressing relfex pointsMaterials preparationThermoplastic polyurethane

The invention relates to a production process of an E-TPU (expanded thermoplastic polyurethane) shoe material. The production process of the E-TPU shoe material comprises the steps implemented in sequence as follows: a, material preparation: 75-92 parts of TPU foamed particles, 5.9-19 parts of glue A, 0.9-4.8 parts of glue B and 0.38-1.5 parts of an accelerator are prepared by weight; b, addition of the glue A: the TPU foamed particles and the glue A are stirred uniformly; c, addition of the glue B: the glue B is added after the materials in the step b are mixed uniformly, and the materials are stirred uniformly; d, addition of the accelerator: the accelerator is added after the materials in the step c are mixed uniformly, the materials are mixed uniformly, and the mixture is injected into a die cavity; e, foaming: the die cavity is moved into an oven, foaming molding is performed at 50-70 DEG C for 2-3 min, and the molded shoe material can be obtained. The TPU particles can account for 90%-92% by weight of the shoe material, the weight reduction limit of the current shoe material is reached, and the E-TPU shoe material has the characteristics of being ultralight, ultrahigh in elasticity, more environment-friendly, low in cost and capable of performing massaging.

Owner:陈茂双

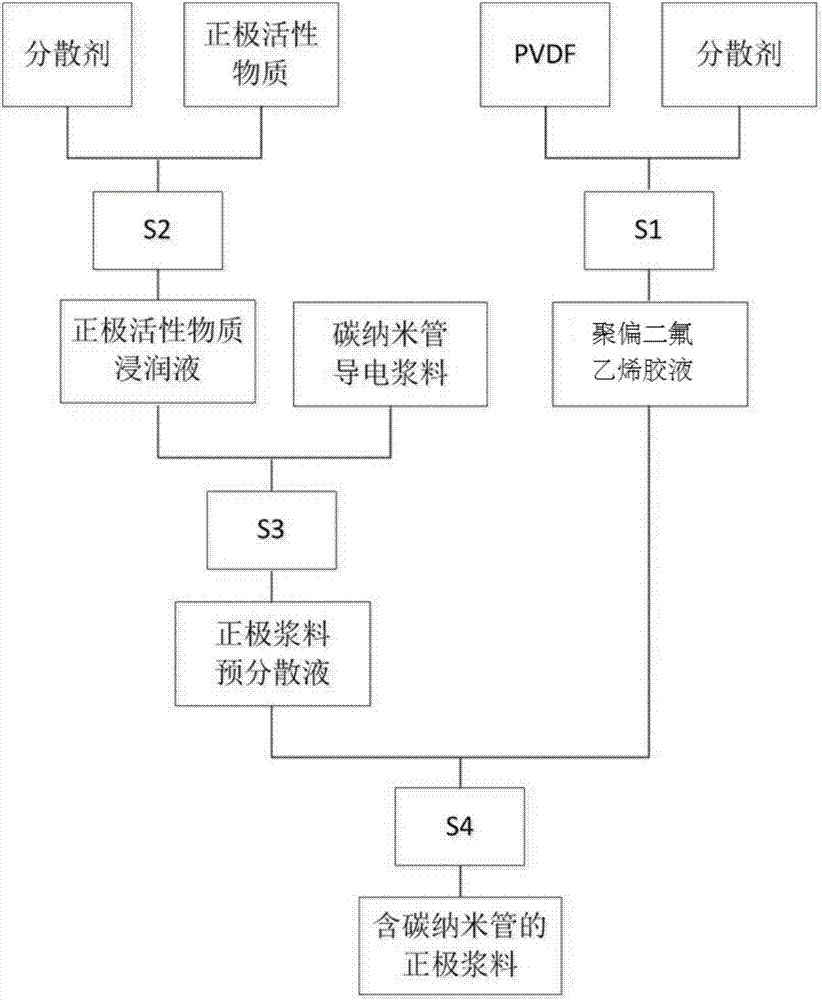

Technology for dispersing carbon nanotubes in lithium ion battery slurry

InactiveCN103606650AImprove electrical conductivityImprove dispersion uniformityCell electrodesPolyvinylidene fluorideElectrically conductive

The invention relates to the technical field of lithium ion batteries and especially relates to a technology for dispersing carbon nanotubes in lithium ion battery slurry. The technology comprises the following steps of 1, carbon nanotube conductive paste preparation, 2, polyvinylidene fluoride glue solution preparation, and 3, lithium ion battery slurry preparation: (1), mixing the polyvinylidene fluoride glue solution and the carbon nanotube conductive paste, (2), adding lithium cobaltate into the mixture for the first time and (3), adding lithium cobaltate and the polyvinylidene fluoride glue solution into the mixture obtained by the step (2) for the second time. The technology improves carbon nanotube dispersion uniformity and solves the problem of too fast agglomeration of the carbon nanotubes and the problem of a too fast rate of lithium ion battery slurry settlement. The carbon nanotubes are uniformly dispersed in the lithium ion battery slurry so that the pole piece of the lithium ion battery is smooth in lithium ion battery slurry coating and thus the pole piece of the lithium ion battery does not have obvious granular feel and has good electroconductivity.

Owner:东莞市金源电池科技有限公司

Stuffing modifier, dumpling and preparation methods thereof

InactiveCN107594323AKeep the clumping performancePreserve tendernessFood coatingGellan gumMonoglyceride

The invention relates to the technical field of food processing and specifically relates to a stuffing modifier, a dumpling and preparation methods thereof. The modifier is prepared from gellan gum, calcium hydrophosphate, xanthan gum, composite phosphate, monoglyceride and corn starch, wherein the gellan gum and the calcium hydrophsphate interact with each other to form gel; thus, under the situation that diced meat is utilized as a stuffing raw material, stuffing huddling performance can be still well kept, and granular sensation of meat stuffing is enhanced; the composite phosphate, the corn starch and the monoglyceride are added to effectively improve water binding capacity; thus, meat tenderness is kept, meat stuffing taste is prevented from being dry and skinny; meanwhile, product texture is improved, granular sensation is obvious when the meat stuffing is eaten, and the meat stuffing has elasticity; the xanthan gum is utilized as a thickener and can absorb moisture precipitatedfrom the meat stuffing, meat stuffing thickness is improved, and production operation is facilitated.

Owner:郑州研霖生物科技有限公司

Jewelry sand blasting technology

ActiveCN106363534AImprove processing efficiencyImprove aestheticsPolishing machinesGrinding machinesGranularitySand blasting

The invention discloses a jewelry sand blasting technology which comprises the steps of forming jewelry, carrying out necessary repairing, shaping and deburring on the outer surface of the embryonic form of the jewelry, polishing the finished product and carrying out sand blasting on the finished product, wherein the sand blasting technology comprises the following steps: (1) drawing on a computer and designating corresponding cutting areas on the drawing; (2) according to the drawing data on the computer, cutting the cutting areas on adhesive sticker; (3) pasting the pattern part of the adhesive sticker to the surface of a to-be-processed product; (4) sand blasting: selecting fine powdery diamond sand with proper granularity as required to carry out sand blasting on the embryonic form of the jewelry; and (5) tearing off the adhesive sticker and washing the jewelry. With adoption of the jewelry sand blasting technology, the adhesive sticker pattern is pasted on the surface of a jewelry to finish pattern processing at one time, so that the pattern lathing technology is eliminated; after sand blasting treatment, polishing treatment on the jewelry is not needed, so that the purpose of simplifying the production technology is realized, manpower and material resources are saved, processing efficiency of the jewelry is effectively improved, and the aesthetic measure of the jewelry is greatly improved.

Owner:LAOFENGXIANG DONGGUAN JEWELRY CO LTD

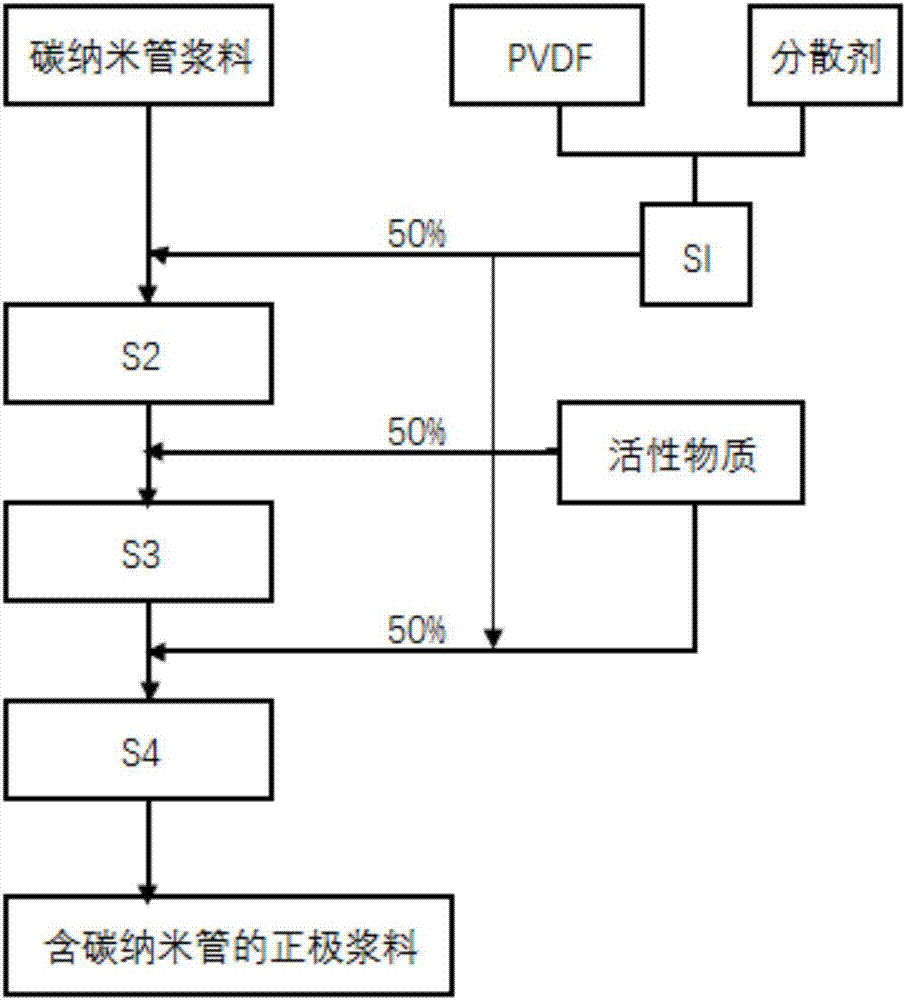

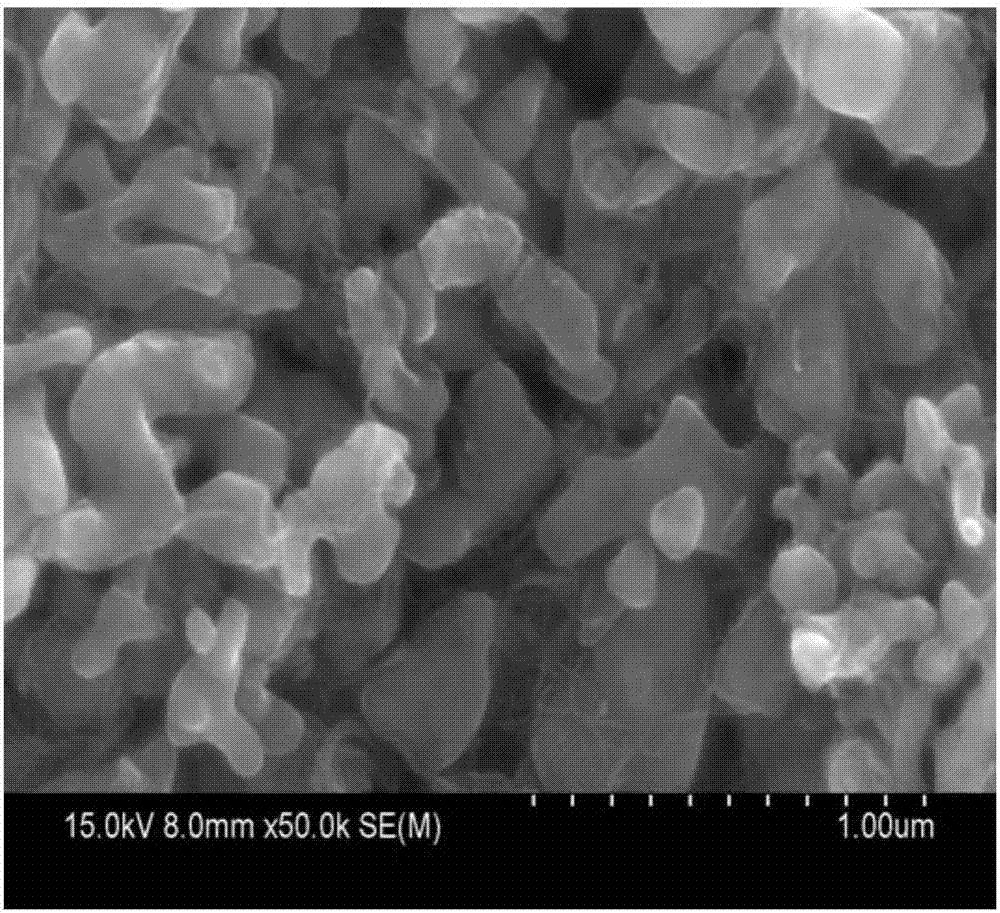

Positive paste containing carbon nanotube and preparation method and application thereof

ActiveCN106876715AGood dispersionFully dispersedCell electrodesSecondary cellsConductive pasteCarbon nanotube

The invention provides uniformly-dispersed positive paste containing a carbon nanotube, a preparation method thereof and application thereof in a lithium ion battery. The method comprises the steps of 1) mixing polyvinylidene fluoride resin and NMP to prepare a polyvinylidene fluoride glue solution; 2) adding a positive active substance into the NMP for immersion to obtain a positive active substance immersion liquid; 3) mixing the positive active substance immersion liquid and the carbon nanotube conductive paste to obtain a pre-diffusion liquid of the positive paste; and 4) mixing the polyvinylidene fluoride glue solution and the pre-diffusion liquid of the positive paste, performing stirring and diffusion, and obtaining the positive paste containing the carbon nanotube after stable stirring under a condition of only starting revolution and not starting rotation. Each constitute in the positive paste is good in dispersion uniformity, the carbon nanotube is high in dispersion uniformity, the problem of excessively fast agglomeration of the carbon nanotube is prevented, the problem of excessively high sedimentation rate of the positive paste of the lithium ion battery is also prevented, and the conductivity of a pole plate prepared from the paste is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Frosted ultraviolet curing coating with high abrasion resistance

InactiveCN106189807AImprove wear resistanceImprove scratch resistancePolyurea/polyurethane coatingsTouch SensesUltraviolet

The invention discloses frosted ultraviolet curing coating with high abrasion resistance. The frosted ultraviolet curing coating comprises, by weight, 20-30 parts of six-functionality urethane acrylate, 20-30 parts of four-functionality urethane acrylate, 8-15 parts of six-function acrylate monomers, 2-4 parts of auxiliaries, 1-5 parts of frosting powder, 20-30 parts of solvents and 2.0-3.0 parts of photoinitiators. The frosted ultraviolet curing coating has the advantages that the scratching resistance of the frosted ultraviolet curing coating can be greatly improved, and sand pattern results are uniformly distributed and are elegant and attractive; the performance of the traditional ultraviolet curing coating can be guaranteed, and the frosted ultraviolet curing coating has touch sense and textures of the sand pattern results.

Owner:SHENZHEN YONGSHENGHUI IND

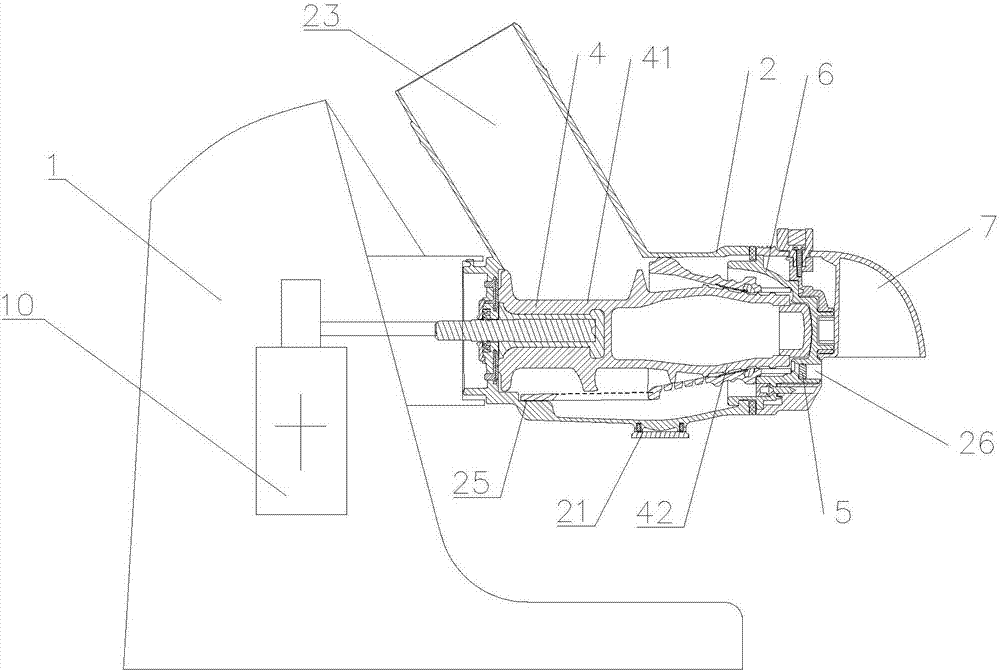

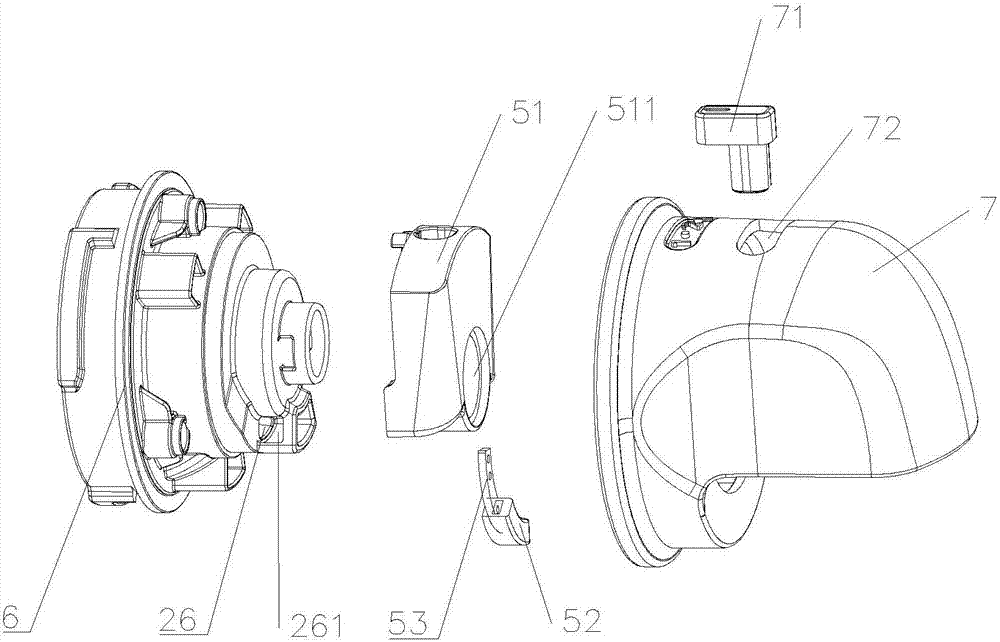

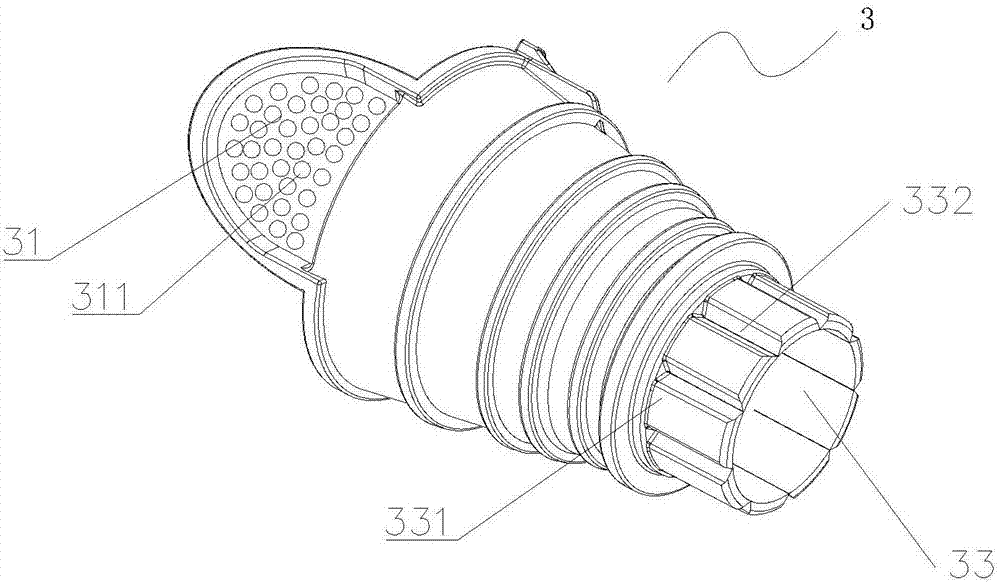

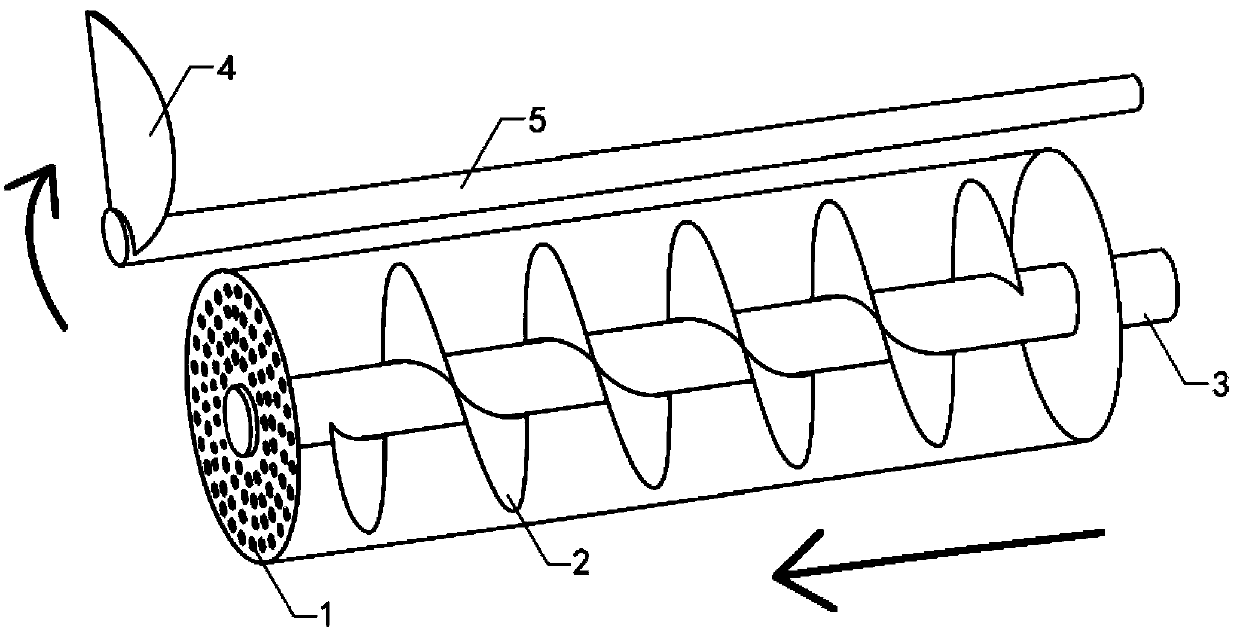

Method for making fruit juice with pulp by using juicer

The invention provides a method for making fruit juice with pulp by using a juicer. The juicer comprises an engine base, a juice collection cavity which is connected with the engine base and a threaded rod and a squeezing container which are horizontally arranged in the juice collection cavity, wherein the threaded rod comprises a material conveying segment and an squeezing grinding segment, the squeezing container is arranged on the outer portion of the squeezing grinding segment of the threaded rod in a sleeving mode, and a juice outlet and a residue outlet are formed in the juice collection cavity; the squeezing container comprises a smashing portion and a filtering portion, a residue discharge adjustment device is arranged in the residue outlet, and the filtering portion comprises a front filtering portion which is arranged at the front end of the squeezing container and a back filtering portion which is arranged at the back end of the squeezing container. According to the method for making the fruit juice with the pulp, through the steps such as regulating steps, squeezing juicing steps and front and back filtering steps, the fruit juice with the content-controllable pulp can be made, so that the fruit juice is rich in nutrition and more diversified in mouthfeel, and the user experiment is improved.

Owner:JOYOUNG CO LTD

Oil-dispersed sodium hyaluronate and preparation method and application of same

The invention discloses an oil-dispersed sodium hyaluronate, a preparation method of the same, and an application of the oil-dispersed sodium hyaluronate to cosmetics. The oil-dispersed sodium hyaluronate comprises, by mass percentage, 1%-50% of sodium hyaluronate, 10-80% of an oil matrix, 0%-30% of a dispersant and 10-50% of a stabilizing agent. The preparation forms include liquid, paste and solid particles. The oil-dispersed sodium hyaluronate related in the invention is prepared by stably and uniformly dispersing water-soluble moisturizing factors, i.e., the sodium hyaluronate, in a micro powder form into the oil matrix, so that the oil-dispersed sodium hyaluronate is convenient for adding into an oil phase or waterless formula of a cosmetic such as a lipstick, a BB cream and a liquid foundation. The oil-dispersed sodium hyaluronate has the efficacy of relieving dry skin due to an oil component, improving makeup-fixing effect and improving stability and lubricity of cosmetics and solves the problem that sodium hyaluronate is difficult to add into cosmetics.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

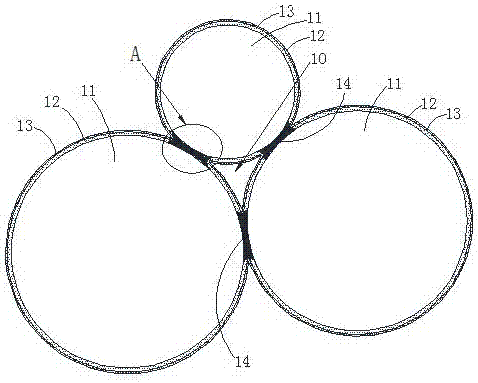

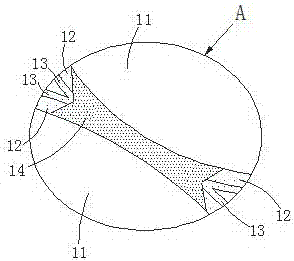

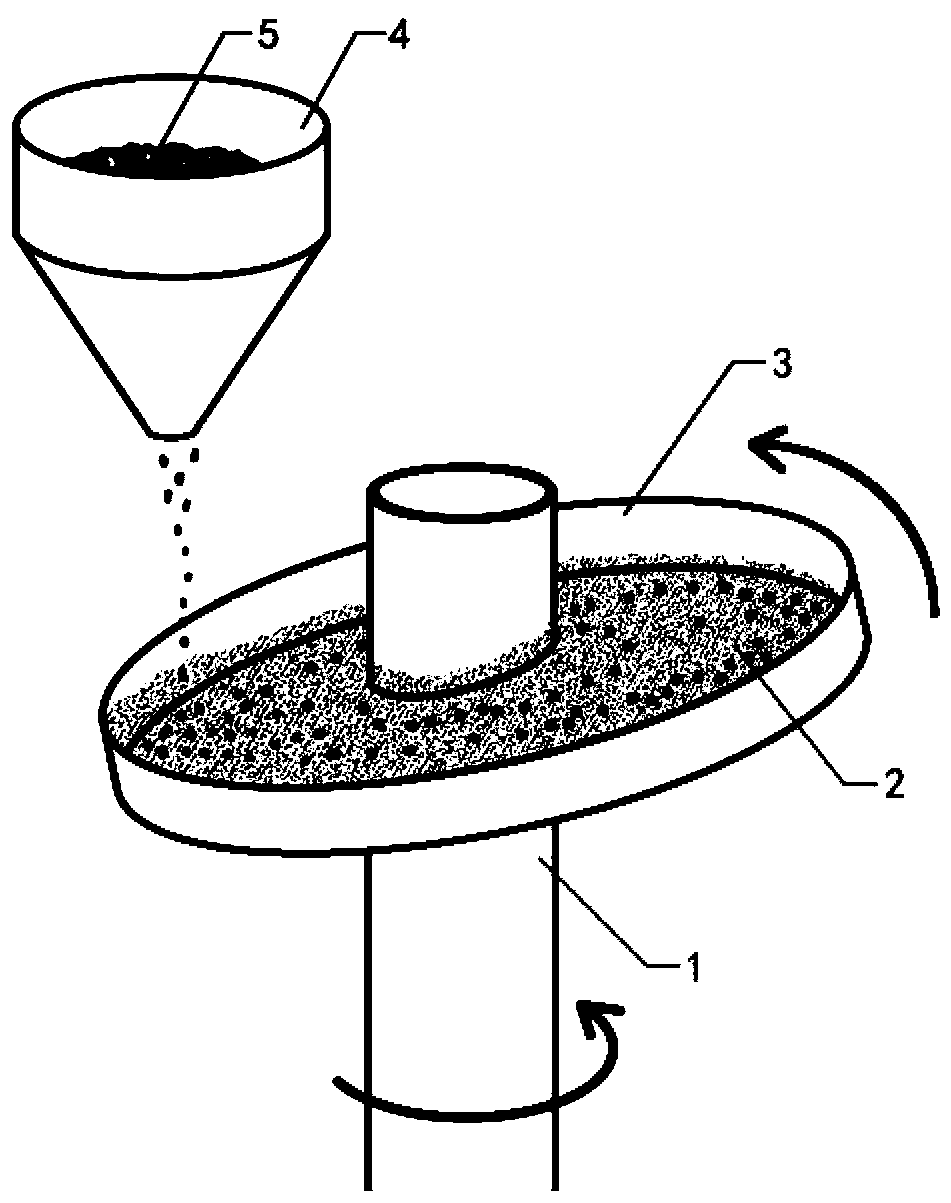

Wrapping type dry granular glaze, wrapping type dry granular glaze cloth ashlar brick and preparation method of wrapping type dry granular size

The invention relates to a wrapping type dry granular glaze, a wrapping type dry granular glaze cloth ashlar brick and a preparation method of the wrapping type dry granular size. The preparation method of the wrapping type dry granular glaze comprises dropwise adding glaze slurry into a rotating disc containing glaze powder so that through the rotating disc, glaze drops can be wrapped with the glaze power to form wrapping type granules, and drying the wrapping type granules to obtain the wrapping type dry granular glaze. The preparation method of the wrapping type dry granular glaze can obtain the wrapping type dry granular glaze through simple processes; the wrapping type dry granular glaze can be applied to preparing ceramic bricks to produce ashlar products vivid in pattern, rich in sense of depth, natural in texture and high in third dimension and granular sensation.

Owner:MONALISA GRP CO LTD

Wallpaper with corn particle effect and production process of wallpaper

InactiveCN103741546AStrong graininessReduce manufacturing costSpecial visual effect coatingsLiquid layerMetallurgy

The invention discloses wallpaper with a corn particle effect. The wallpaper is characterized in that a pre-coating liquid layer is formed on a substrate, and an uneven foaming slurry layer is formed on the pre-coating liquid layer and is obvious in unevenness and strong in granular sensation. Meanwhile, the invention discloses a production process of the wallpaper with the corn particle effect. The production process has the advantages that production materials are easily available, and the production cost is low.

Owner:FUJIAN SUNREAL PRO ENVIRONMENTAL WALLPAPER

Vehicle lamp figure and production method thereof

PendingCN108224355AGuarantee lighting uniformityStrong graininessVehicle headlampsLighting and heating apparatusEngineeringSimple polygon

Owner:HASCO VISION TECHNOLOGY CO LTD

Oxford spinning fabric

The invention discloses an oxford spinning fabric, belongs to the technical field of spinning and particularly relates to a production technology of the oxford spinning fabric. The oxford spinning fabric is of a double-end texture, C50S compact spinning cotton yarn is formed in the warp direction, C8S ring spinning combed cotton yarn is formed in the weft direction, and the texture structure is weft ribs or squares. By adjusting yarn for a conventional oxford spinning fabric, the produced oxford spinning fabric has the advantages of being soft, thick, soft and breathable; due to the special point-shaped texture of a cloth cover, the granular sensation is stronger, third dimension is stronger, the oxford spinning fabric is more glossy, the fabric is better in sewability, and the fabric can be used in a cold area in the north of China. Particularly, 8 thick combed cotton yarn counts are adopted as weft yarn counts, the liquid ammonia finishing procedure is performed after matching, the fabric is softer and more comfortable in touch, split defects of the cloth cover are eliminated, the touch is thick and solid, and the requirement of a consumer for the cold area in the north of China is met.

Owner:JIANGSU JAMES TEXTILE

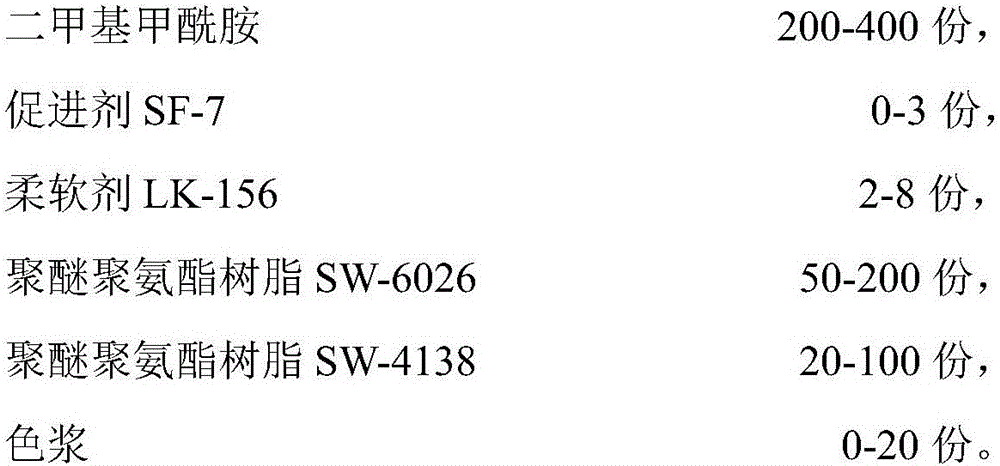

Preparation method of polyurethane synthetic leather for soft-suede high-elasticity leather-imitated sofa furniture

The invention discloses a preparation method of polyurethane synthetic leather for soft-suede high-elasticity leather-imitated sofa furniture. According to the preparation method, a suede elastic fiber synthetic cloth base with good elasticity and toughness is adopted, a plush surface is taken as a front surface during wet process processing, and a knife-scraping and impregnation once forming process is adopted, so that the impregnation volume of slurry of the cloth base can be increased, the combination between polyurethane resin and suede fiber cloth base is relatively tight, and the bonding strength is relatively high; meanwhile, a buffing machine is utilized for carrying out buffing-galling process processing, so that the flatness and the bonding strength are relatively high during dry method veneering; soaking and line-rubbing aftertreatment is carried out. The finished polyurethane synthetic leather for the leather-imitated sofa furniture is not provided with a wet process layer and is more approximate to leather, surface patterns are more plump, the granular sensation on the back is strong, the touch feel is fine, flexible and plump, and the leather sense is strong; meanwhile, the polyurethane synthetic leather has the characteristics that the peel strength is high, the wear resistance is high, the normal-temperature deflection is good, the tear strength is high, the hydrolysis resistance can reach 3 years, and the cost performance is very high.

Owner:ANHUI ANLI MATERIAL TECH

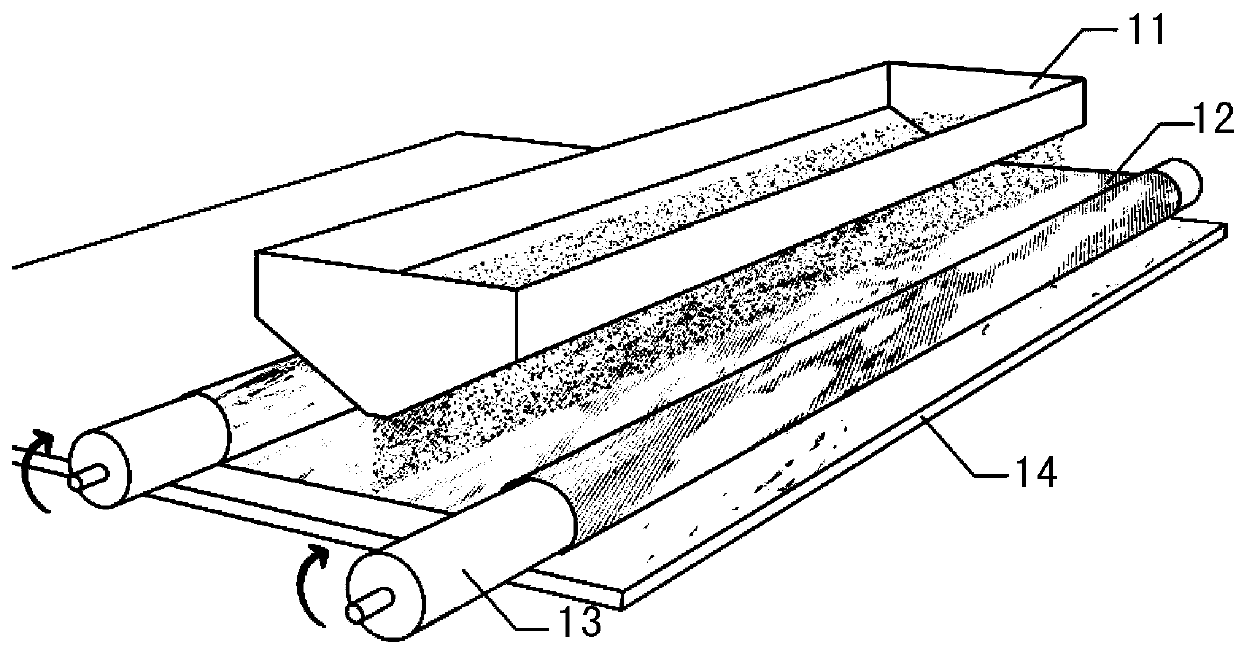

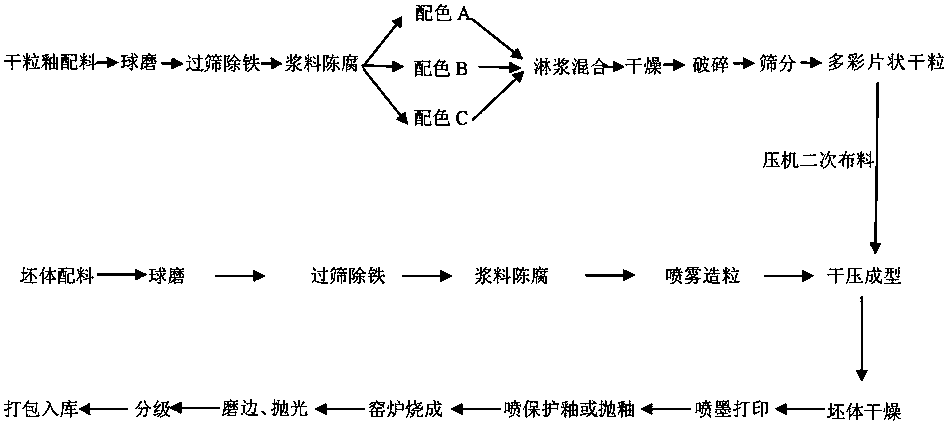

Colorful flake dry grain glaze and flake dry grain glaze cloth imitation stone brick, and production methods thereof

The invention relates to a colorful flake dry grain glaze and a flake dry grain glaze cloth imitation stone brick, and production methods thereof. The production method of the colorful flake dry grainglaze comprises the following steps: mixing glaze slips having different colors to form a colorful glaze slip, spraying the colorful glaze slip in a tray, drying the colorful glaze slip to obtain a colorful slurry layer, and breaking and sieving the colorful slurry layer to obtain the colorful flake dry grain glaze. The colorful flake dry grain glaze can be obtained through the simple method, andthe colorful flake dry grain glaze can be used in the production of ceramic bricks to obtain the imitation stone material product having accurate pattern, plentiful layers, natural texture, strong stereo perception and strong granular sensation.

Owner:MONALISA GRP CO LTD

Preparation method of healthy fat-reduction multi-grain bread with rich dietary fiber

InactiveCN107549253AIncrease in sizeIncrease elasticityDough treatmentPre-baking dough treatmentCooking & bakingSoybean hulls

The invention discloses a preparation method of healthy fat-reduction multi-grain bread with rich dietary fiber. The method comprises the steps that firstly, a mode that enzymolysis and alkaline hydrolysis are combined is used for treating soybean hull powder, soybean hull powder dietary fiber is obtained and smashed in a jet mill with special frequency, soybean hull powder dietary fiber fine powder is obtained, and part of bread powder is replaced by the fine powder to prepare the multi-grain bread. According to the preparation method, through reasonable matching and technological modification, firstly, main raw materials are dry-blended, the weight of the powder is kept even, then a certain amount of water is added into the powder and stirred, stirring is conducted for a period, and thena certain amount of salt and dried yeast are added into the mixture; then paste is subjected to secondary fermentation and then put into an oven, a mode of first fire baking is adopted, the paste ispromoted to be fermented continuously, under the effect of shortening, bubbles can be wrapped in the baking process, air loss is prevented, and the volume and elasticity of the paste are improved; theprepared multi-grain bread is good in taste, even in quality, good in structural state and fine and smooth in taste.

Owner:ANHUI HUAZHIHUI ECOLOGICAL AGRI DEV

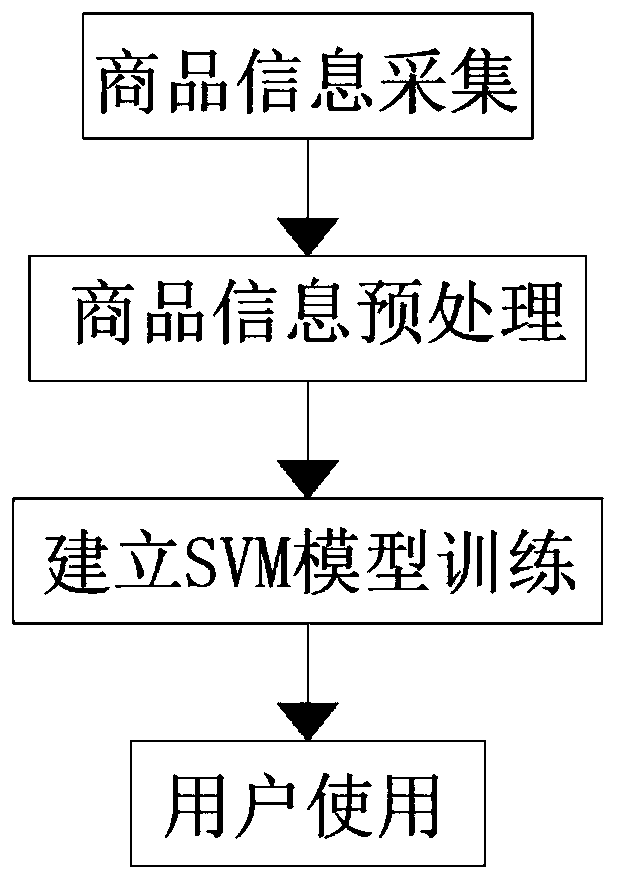

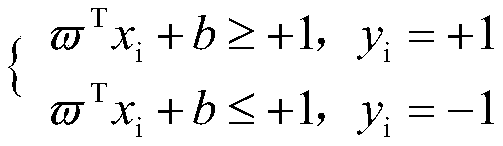

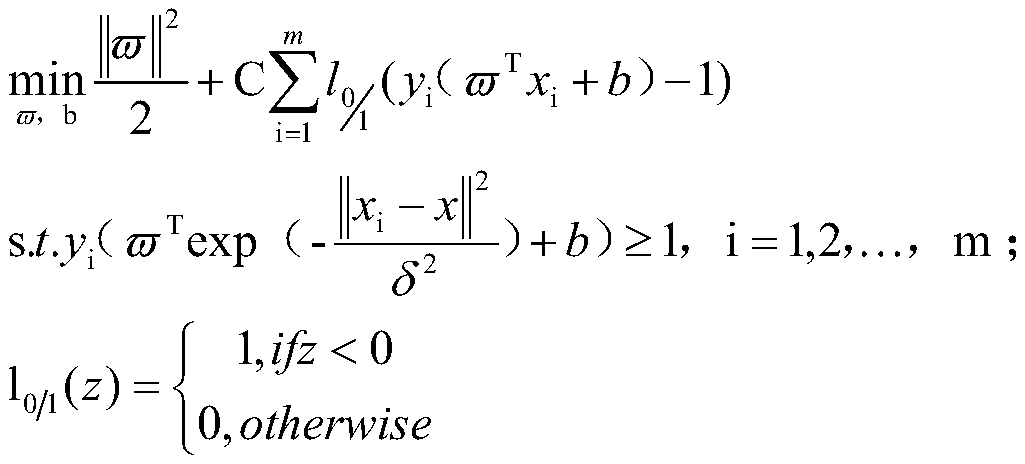

Commodity appearance anti-counterfeiting method based on SVM image or video recognition

InactiveCN110135491AReduce the chance of buying counterfeit goodsAnti-counterfeiting identification technology upgradeCharacter and pattern recognitionCommercePattern recognitionVideo recognition

The invention discloses a commodity appearance anti-counterfeiting method based on SVM image or video recognition, which belongs to the technical field of commodity anti-counterfeiting, and comprisesthe following steps of: acquiring commodity information, carrying out omnibearing video acquisition on a real commodity by a manufacturer, respectively recording a plurality of copies in different environments, marking to be a genuine product, and uploading a video to the system after the acquisition is finished; preprocessing commodity information; establishing an SVM model for training and usingby a user. An anti-counterfeiting identification mode with an identification standard closer to real person identification can be provided. Consumers can identify true and false commodities more quickly and accurately, the condition that the consumers buy the false commodities is greatly reduced, merchants can upgrade the anti-counterfeiting identification technology of own products correspondingly, and the competitiveness of own products is improved while the own genuine products are protected.

Owner:四川中新华搜信息技术有限公司

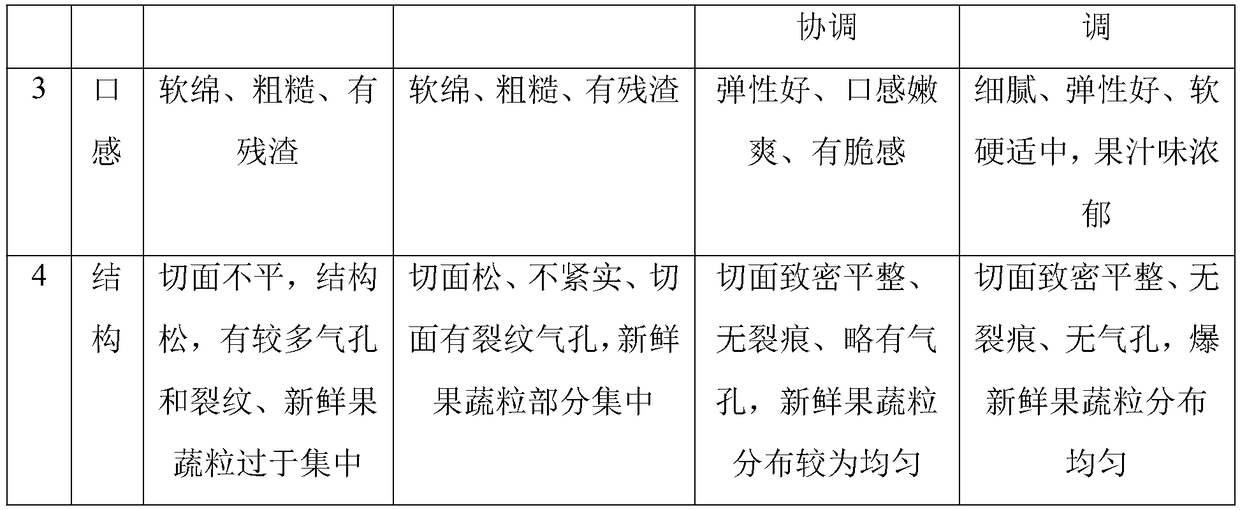

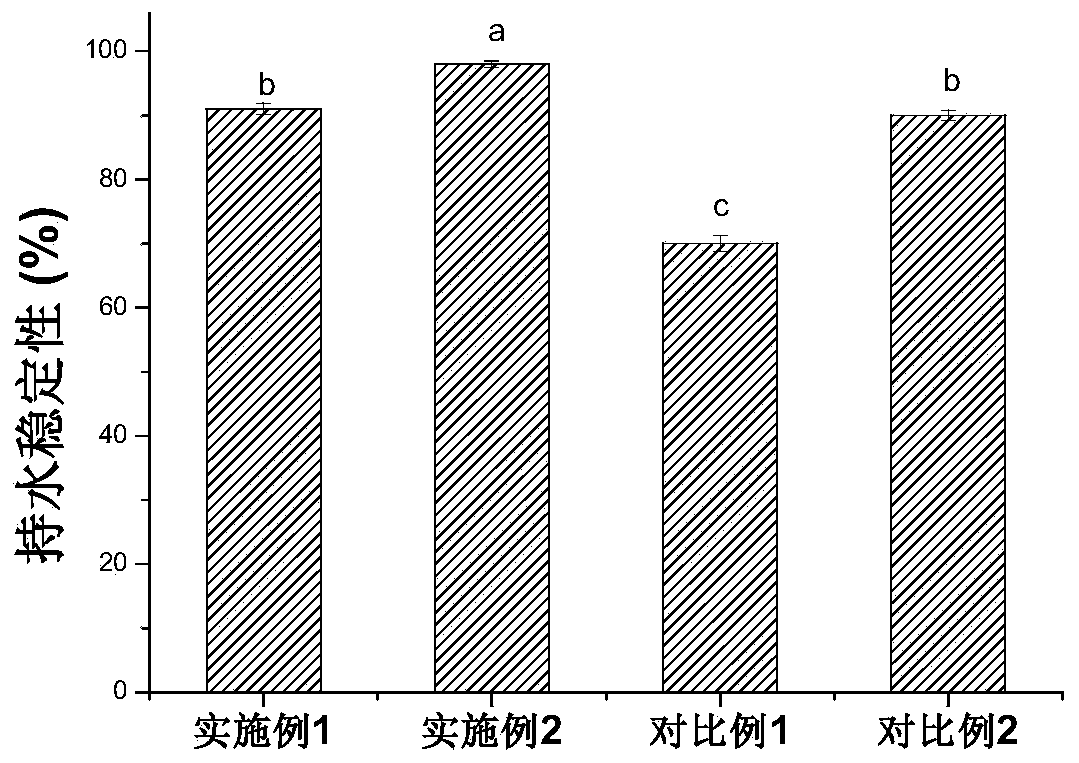

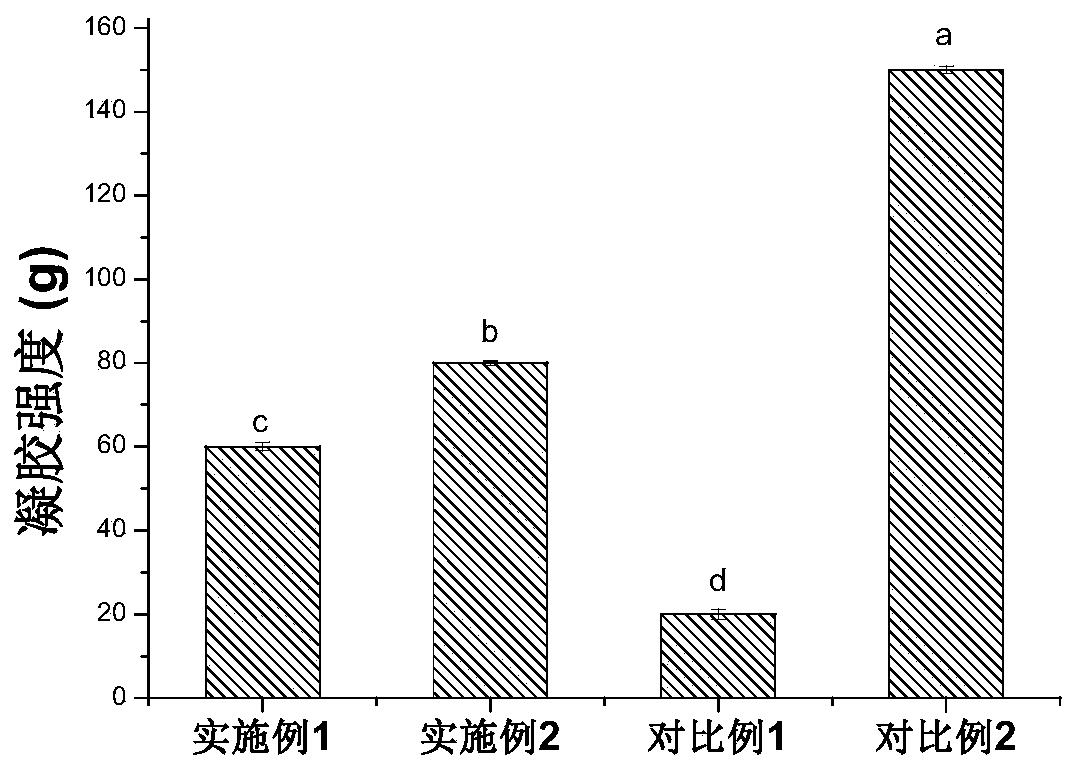

Sausage containing fresh fruit and vegetable grains and preparation method thereof

InactiveCN109452568AReduce nutrient lossBeautiful and fragrantFood ingredient as antioxidantFood coatingEmulsionNutrient content

The present invention relates to the field of meat product food and relates to a sausage containing fresh fruit and vegetable grains and a preparation method thereof. The provided new preparation technology preserves nutrients, crispness and juicy mouthfeel of fruits and vegetables, and the fruit and vegetable grains are added into the sausages to prepare the sausage having meat mouthfeel and alsohaving fruit and vegetable mouthfeel. The prepared fresh fruit and vegetable grains are wrapped once using an emulsion, then the wrapped fruits and vegetables are wrapped by using hot irreversible glue, after the wrapped fruits and vegetables are mixed with meat stuffing, the mixture is subjected to a low-temperature gradient aging and sterilizing technology, and the mouthfeel and nutrients of the fresh fruits and vegetables are completely preserved.

Owner:湖南唐人神肉制品有限公司

Rice processing method

Owner:扬州市金谷农副产品专业合作社

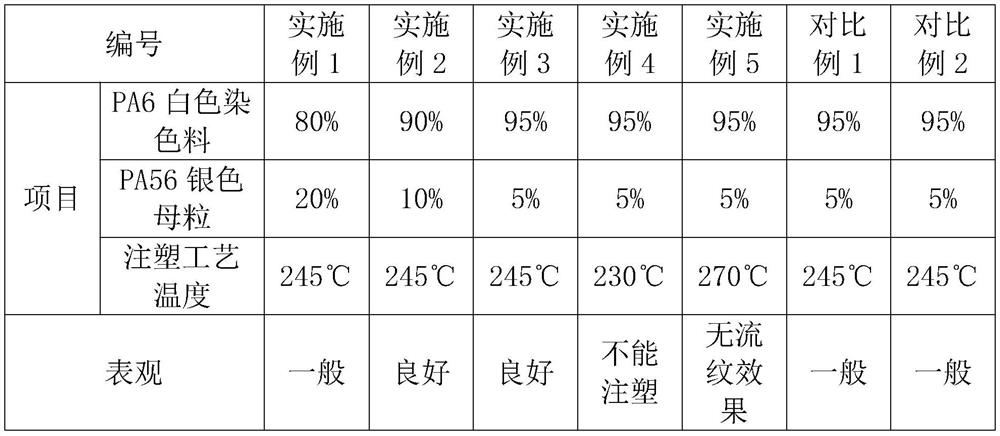

PA6/PA56 flow liner silver apparent material and preparation method thereof

The invention discloses a PA6 / PA56 flow liner silver apparent material which is prepared from the following raw materials in parts by weight: 4-19 parts of a PA6 white dyeing material and 1 part of a PA56 silver master batch. The PA6 resin has high flowability and certain surface gloss due to material characteristics, the high-temperature PA56 is softened and dispersed in the low-temperature PA6 by manufacturing two dyeing materials with different colors and utilizing different melting points of the two materials PA6 and PA56, the high-temperature PA56 is oriented in the ejection direction and is in a flow liner shape, the material cost is low, and the material can be applied to elevator decorative plates, storage boxes and the like to replace traditional plastic paint spraying parts.

Owner:上海聚威新材料股份有限公司

Production method of diet food with fishes as raw material

PendingCN111109551AIncrease profitDifficult to processFood freezingFood ingredient as gelling agentBiotechnologyAnimal science

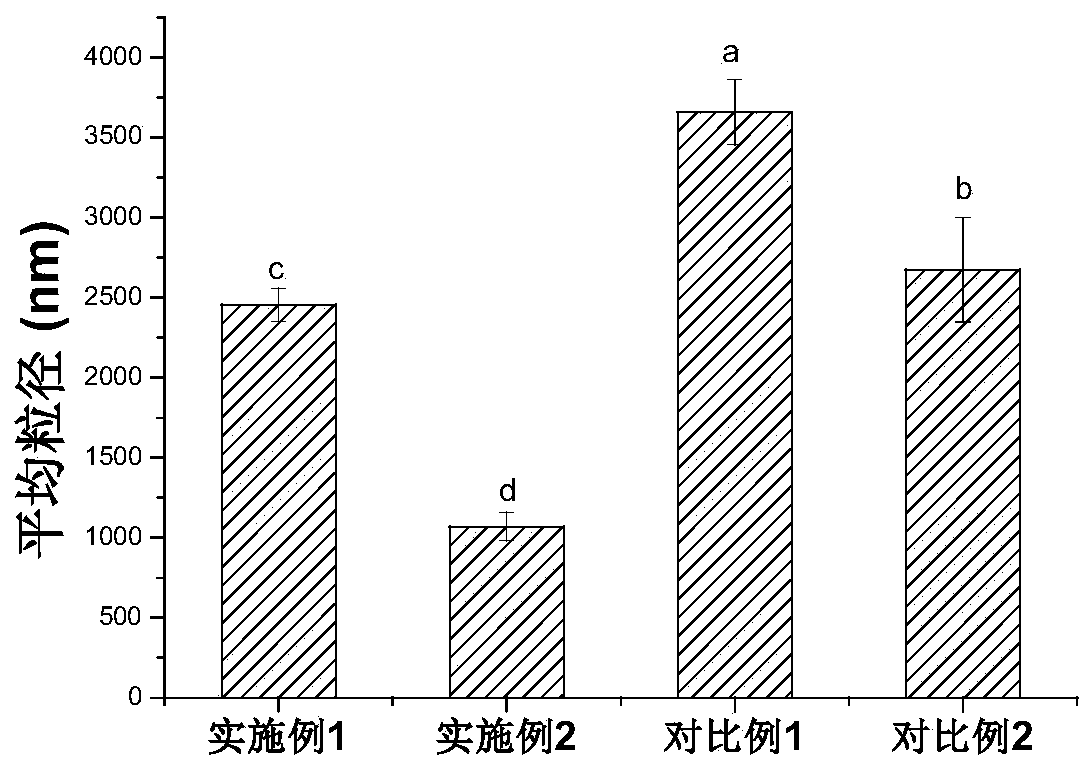

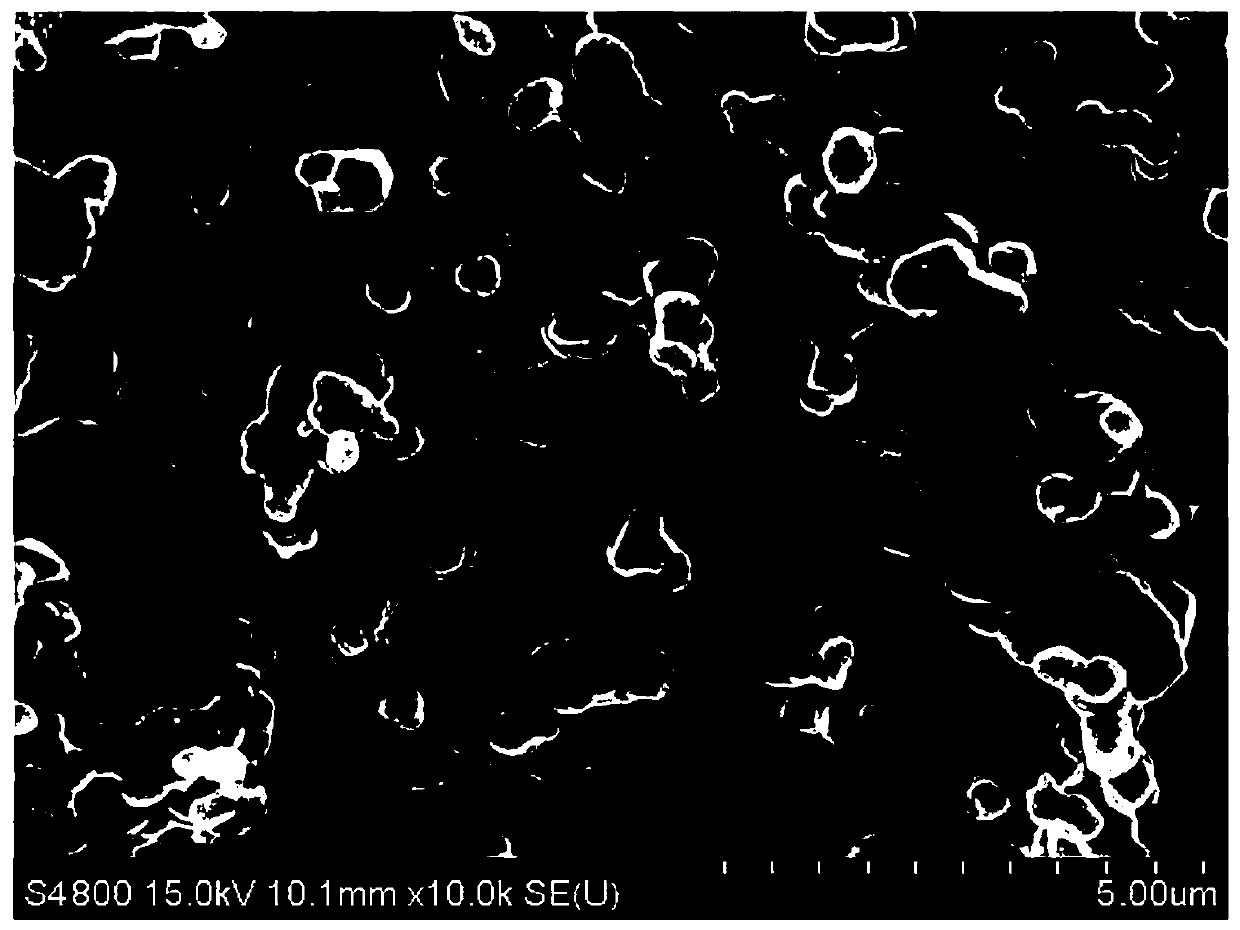

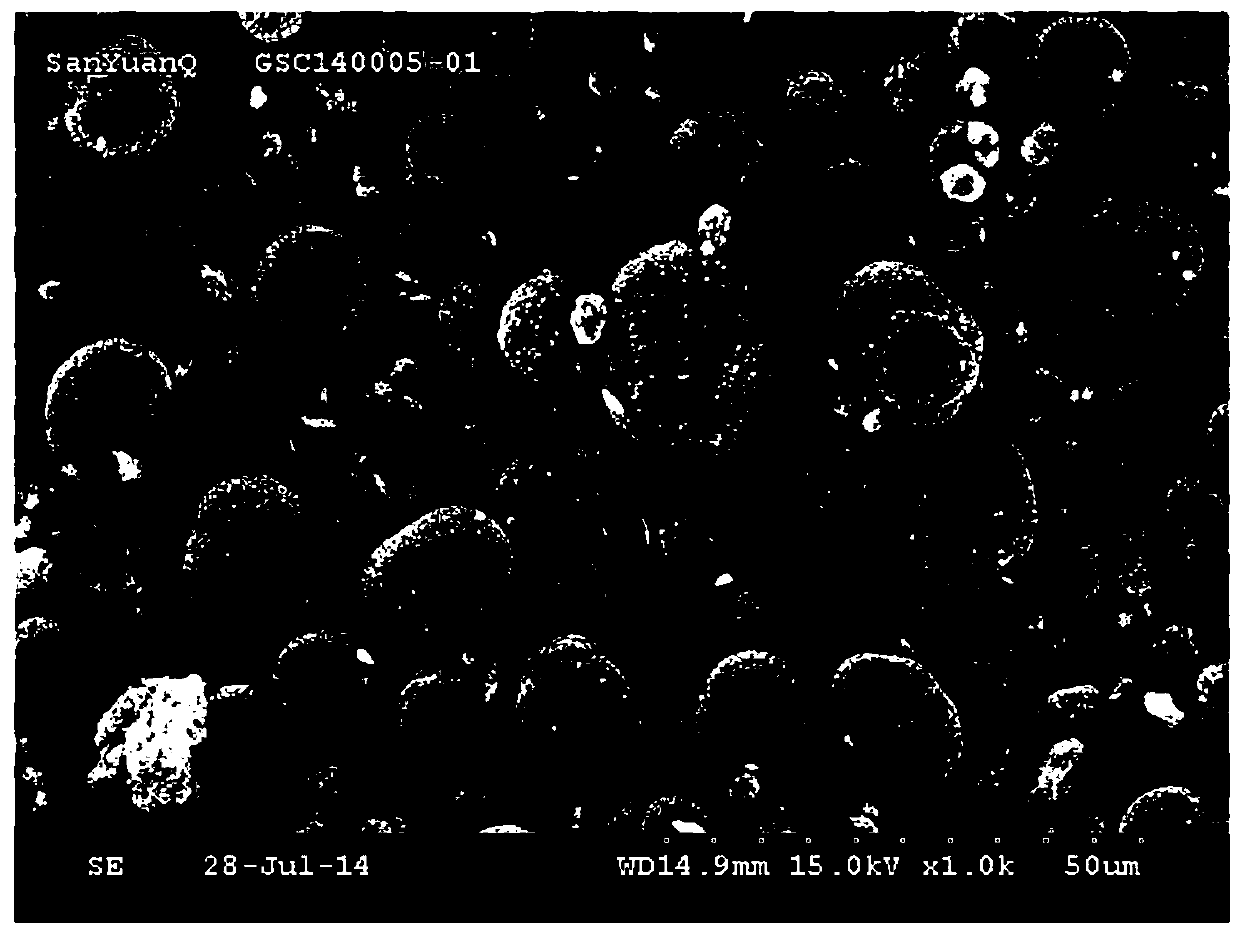

The invention discloses a production method of diet food with fishes as a raw material. The production method of the diet food with the fishes as the raw material comprises the following steps: addingwater into cooked fish, and crushing an obtained mixture by means of a colloid mill with processing granularity of 1-9 [mu]m into a paste; adding a pre-processed gelatin solution into the paste to obtain pulp, so as to make the content of hydroxyproline in the pulp equal to 200-500 [mu]g / g and to make the total content of gelatin in the pulp account for 2%-5% of the weight of the pulp; homogenizing the pulp to obtain cream, so as to make the particle size of the cream equal to 100-5000 nm and to make the average particle size equal to 100-3000 nm; and conducting filling and sterilizing on thecream to obtain the diet food. By means of the production method of the diet food with the fishes as the raw material, the fish with a rough taste is refined into micron-sized or even nano-sized particles, and a product with layered solid and liquid is processed to achieve an even stale state; and texture properties of a solid meat product are changed so that people with poor swallowing functionscan fully take in food, and accordingly the risk of malnutrition caused by choking is avoided.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Lithium ion battery cathode material, preparation method and lithium ion battery

ActiveCN105449169BImprove storage effectEven distribution of elementsCell electrodesSecondary cellsElectrical batteryPhysical chemistry

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

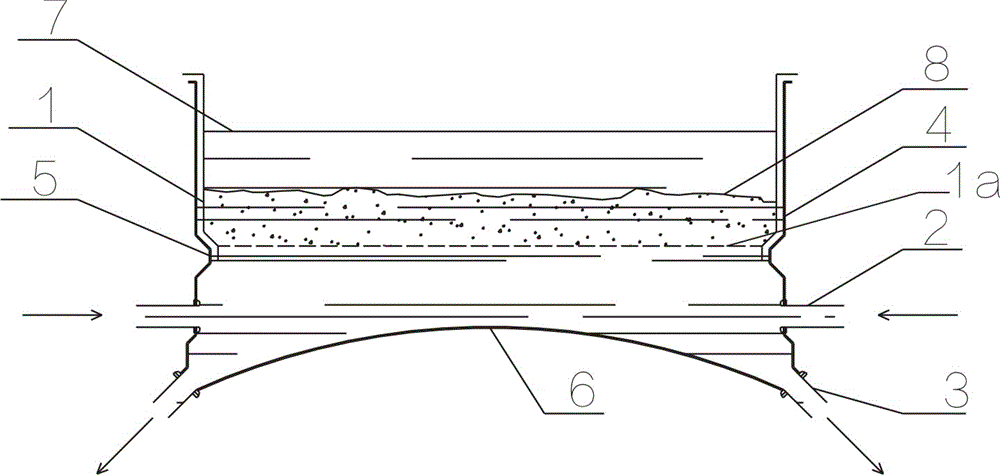

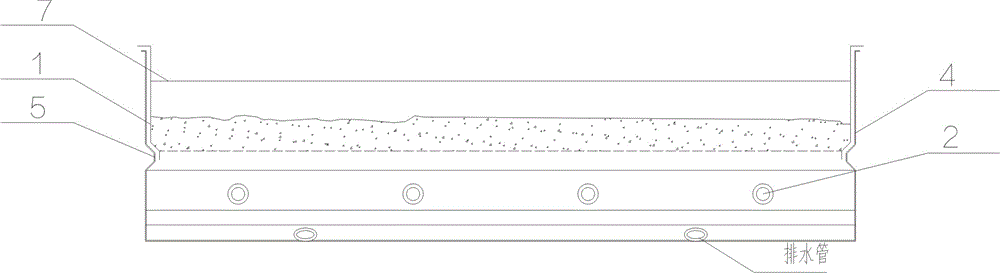

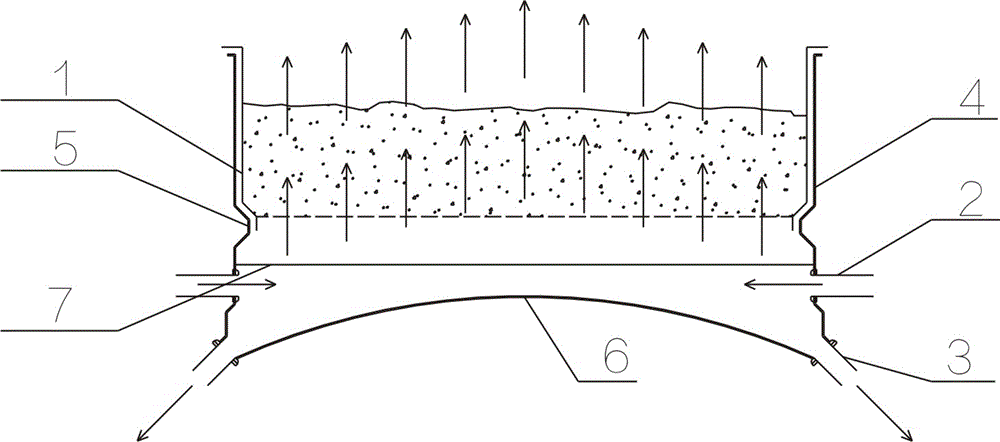

Rice making process and rice steaming equipment

InactiveCN105558758AReduce graininessStrong graininessCooking vesselsFood scienceRice dishesOperation mode

The invention discloses a rice making process and rice steaming equipment. The rice making process comprises the following steps of 1, rice boiling: putting rice grains into a rice container; adding a corresponding amount of water; boiling the rice grains to the cooked degree required by later-stage steaming; 2, water discharging: after the boiling is completed, discharging rice boiling water inside the rice steaming equipment; 3, rice steaming: A: after the discharging of the rice boiling water is completed, adding a proper amount of water, then, performing heating for forming steam, and steaming the rice grains boiled in the rice container; B, directly adding steam into rice steaming equipment through a water inlet and air inlet pipe for steaming, and completing the process of making uncooked rice into cooked rice. Compared with the prior art, the rice making process has the advantages that the operation mode of firstly boiling and then steaming is used; the rice made by the method absorbs less water than that in the prior art since the boiled water is separated in the rice cooking process and the steam is used for cooking in a later period, so that the rice made by the rice making process has higher rice grain feeling, and the mouthfeel is also effectively improved.

Owner:段迅 +1

Colorful antiskid floor paint as well as preparation method and construction method thereof

PendingCN111234656ASolve the technical problem of small friction and non-slipIncrease coefficient of frictionEpoxy resin coatingsFlooringFirming agentResin coating

The invention provides a colorful antiskid floor paint which is composed of a component A and a component B. The component A is prepared from the following raw materials in parts by weight: 30-50 parts of epoxy resin, 30-40 parts of quartz, 5-15 parts of an active diluent, 2-6 parts of a functional aid, 5-20 parts of color paste and 5-10 parts of wear-resistant powder. And the component B is prepared from 15-25 parts of an epoxy curing agent. The surface area of the epoxy resin coating is increased; improving roughness thereof, the friction coefficient of the material surface is increased; theinvention innovatively provides an epoxy floor coating mode, the epoxy floor coating mode has the effects of rich colors and various colors, the decorative property and the practicability are extremely high, the aesthetic feeling of floor coating is greatly improved, and by adopting a granular spraying construction mode, the colorful anti-skid floor paint can achieve the technical effects of uniform distribution and various colors. The preparation method of the colorful antiskid floor paint is simple and suitable for large-scale production and application.

Owner:DACHANG BBMG COATING CO LTD

Tomato, corn and beef dumpling and making method of tomato, corn and beef dumpling

The invention belongs to the technical field of foods, and particularly discloses a tomato, corn and beef dumpling and a making method of the tomato, corn and beef dumpling. Dumpling stuffing comprises, by weight, 10% to 25% of cooked beef granules, 10% to 30% of pork lean meat, 10% to 25% of pork fat, 3% to 15% of tomatoes, 5% to 15% of onions, 5% to 15% of scrambled eggs, 10% to 25% of quick-frozen corn granules, 5% to 10% of tomato paste and 1% to 6% of tomato sauce. According to the tomato, corn and beef dumpling, the tomato paste, the tomato sauce and the like serve as special seasoning, the cooked beef granules serve as main materials, the pork meat is used as auxiliary materials, the raw materials including the onions, the eggs, the corn granules and the like are used in cooperation, the fragrant and sweet tomatoes and fragrant and sweet corns are mixed, and the delicious taste is further upgraded; in addition, a beefsteak cooking mode is adopted for beef, the granule feeling of the beef in the dumpling is high, the chewy feeling is sufficient, and a consumer can practically feel the texture of the beef. The tomato, corn and beef dumpling is abundant in nutrition, reasonable in matching and suitable for various persons, and is particularly enjoyed by ladies and children greatly.

Owner:ZHENGZHOU SYNEAR FOOD

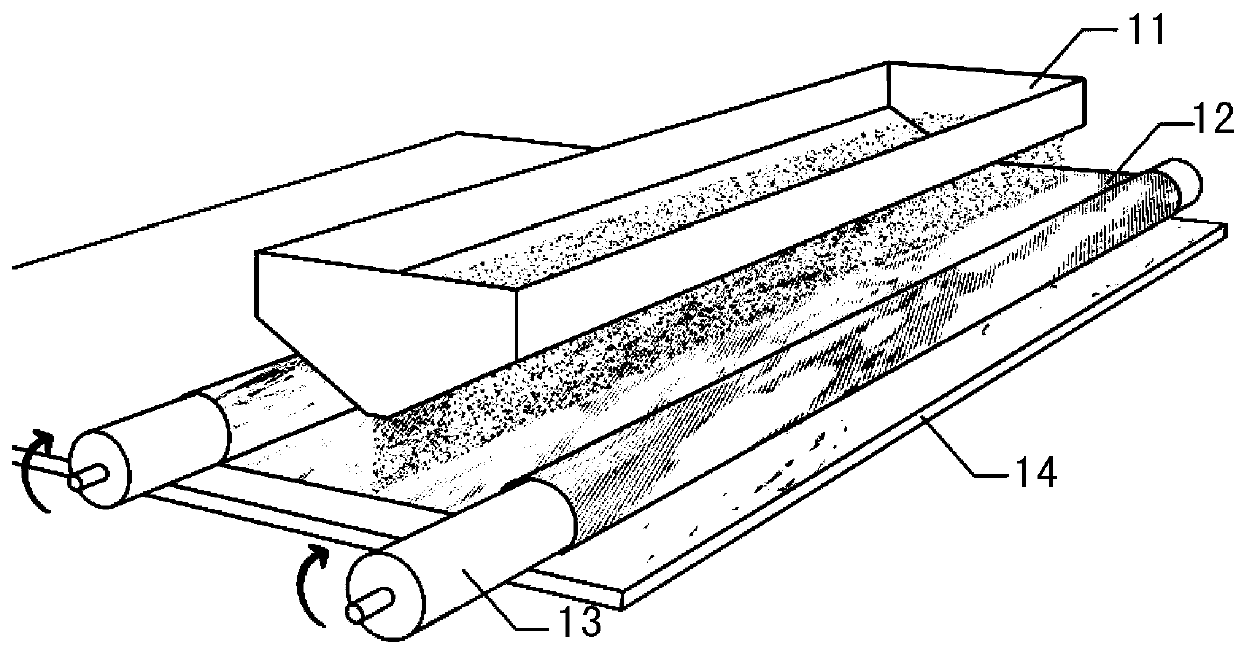

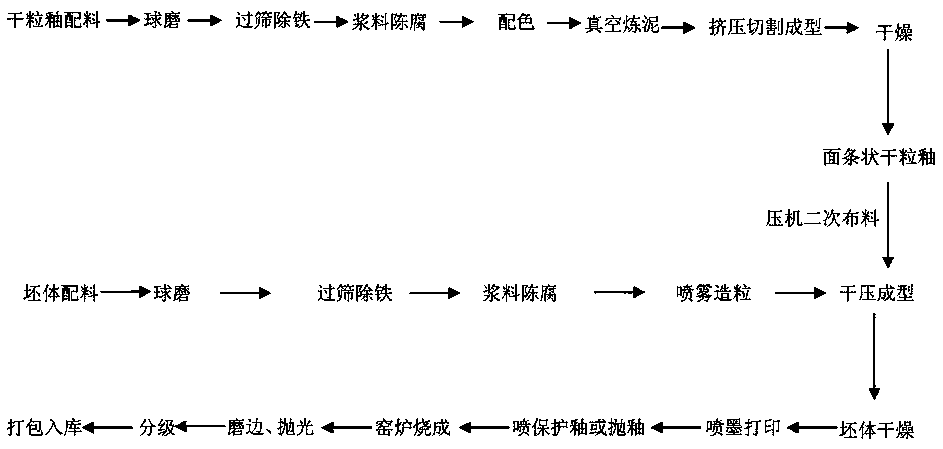

Noodle-shaped dry granular glaze, noodle-shaped dry granular glaze cloth ashlar brick and preparation method thereof

InactiveCN107932686ARich layersNatural textureNatural patternsCeramic shaping apparatusCeramic glazeCeramic tiles

The invention relates a noodle-shaped dry granular glaze, a noodle-shaped dry granular glaze cloth ashlar brick and a preparation method thereof. The preparation method of the noodle-shaped dry granular glaze comprises the steps that glaze slip with color is produced into a mud cake; and a noodle-shaped glaze mud is extruded out of the mud cake, and the noodle-shaped dry granular glaze is obtainedafter drying. The noodle-shaped dry granular glaze can be obtained by simple process, and can be used in the preparation of ceramic tile, and imitation stone production with realistic pattern, rich layers, natural texture, third dimension and strong granular sensation can be obtained.

Owner:MONALISA GRP CO LTD

Sintered quartz sand wall-like coating

InactiveCN106978081AGood weather resistanceImprove waterproof performanceCement coatingsNonwoven fabricWater spray

The invention provides a sintered quartz sand wall-like coating. The sintered quartz sand wall-like coating comprises an aqueous primer, a cohesive nonwoven fabric, a sintered quartz sand medial coating and an aqueous top coating from the inside to the outside. The sintered quartz sand wall-like coating is beautiful and elegant, has soft color and uniform particles, and is suitable for villas and high-grade civil buildings. A composite coating layer formed by the sintered quartz sand wall-like coating has excellent corrosion resistance, can resist weather for 20 years, and has a strong self-cleaning function and a clear beautifying and decorating function; a unique scraping construction technology is carried out after adopting the cohesive nonwoven fabric, so the adhesion of the coating and a substrate is improved, the use amount of the coating is reduced, and the construction cost of the coating is reduced; and the nonwoven fabric and a building glue layer have an excellent waterproofing effect, and reduce exterior wall water spraying leaking points.

Owner:HUBEI WUDA LUOJIA INSPECTION & CONSULTATION OF ENG STRUCTURE

Sirloin beef dumpling and production method thereof

The invention belongs to the technical field of food technologies, and particularly discloses a sirloin beef dumpling and a production method of the sirloin beef dumpling. Stuffing of the sirloin beef dumpling comprises, by weight, 10-25% of cooked-beef granules, 10-30% of pig lean meat, 5-10% of pig fat, 5-15% of onions, 10-30% of asparagus lettuce, 5-15% of water chestnuts, 0.2-1% of black pepper, 0.5-3% of white sesame seed powder, 2-8% of XO sauce, and 1-5% of barbeque sauce. The sirloin beef dumpling has a special flavor formed by combining tradition and innovation, the flavor is novel and unique, the nutrition arrangement is reasonable, the taste is delicious, the seafood taste is rich, the granular sensation of sirloin beef is strong, the cooked-beef granules are chewy, and the sirloin beef dumpling brings different enjoyment of food to consumers and is suitable for all kinds of people to eat.

Owner:ZHENGZHOU SYNEAR FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com