Wrapping type dry granular glaze, wrapping type dry granular glaze cloth ashlar brick and preparation method of wrapping type dry granular size

A technology of dry granule glaze and encapsulation, which is applied in the field of ceramic tile production and manufacturing, and can solve the problems of single decorative effect of tiles and difficulty in imitating natural stone effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention. In addition, in the present invention, unless otherwise specified, the content percentages all refer to mass percentages.

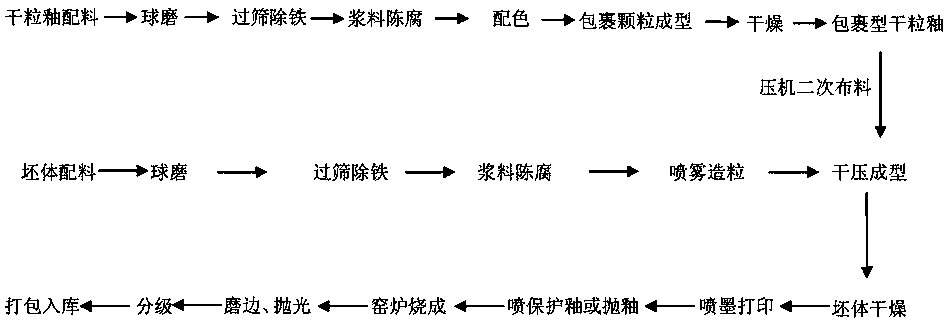

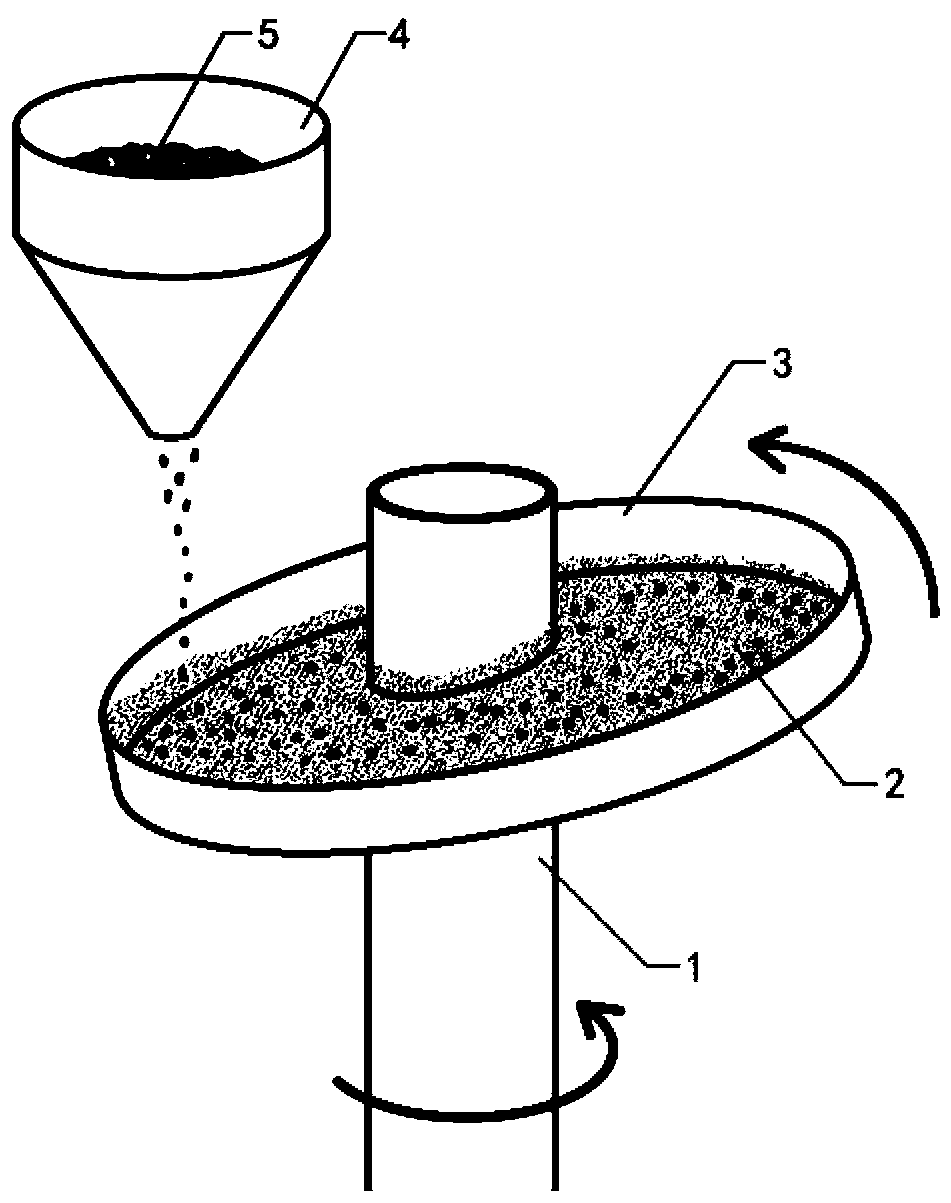

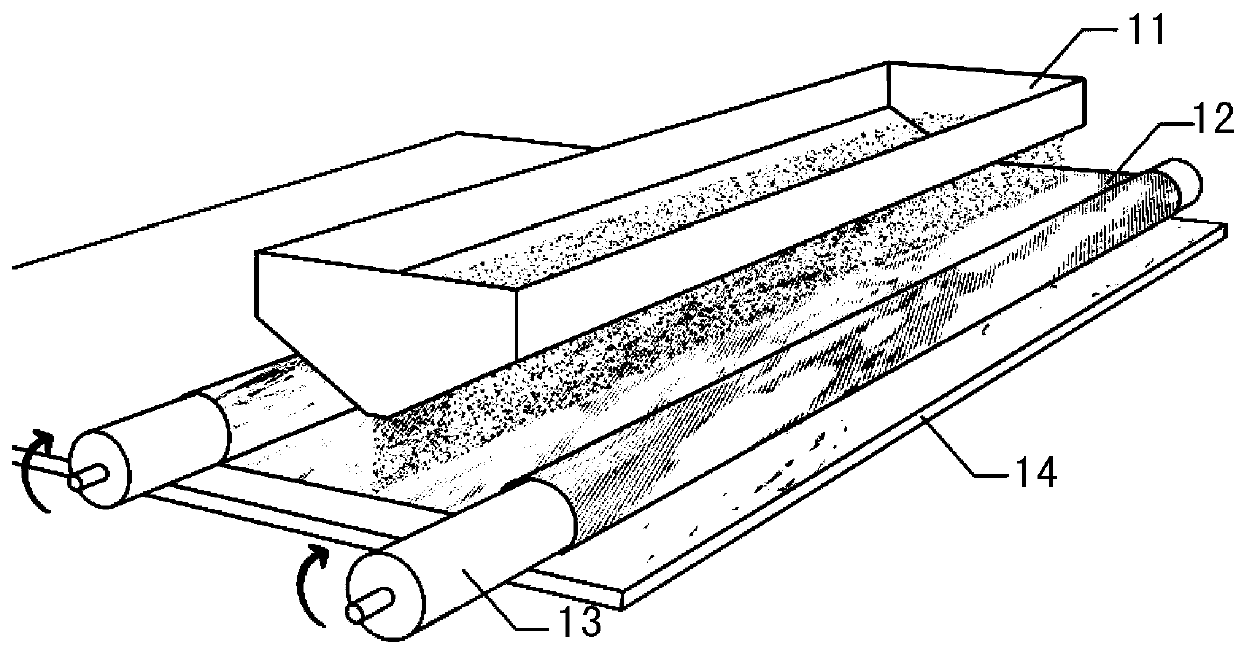

[0045] In one embodiment of the present invention, dry grain cloth and inkjet printing are combined, and on the basis of careful research and analysis of the surface texture of natural stone, through high-precision scanning and aesthetic processing, a variety of unique imitation natural stone textures are designed. Effect fabric film patterns and inkjet patterns. During production, the packaged dry granule glaze is first prepared, and then the packaged dry granule glaze is layered and distributed on the blank according to different patterns. Optionally, the packaged dry gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com