Method for making high-definition high-fidelity color picture of TPW 10 mu m on surface of paper

A surface production, high-definition technology, applied in printing, printing devices, etc., can solve the problems of not being able to express the true colors of nature, unclear changes in tone and shade, and insufficiently detailed patterns, etc., to achieve rich layers, uniform tones, and a strong sense of hierarchy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

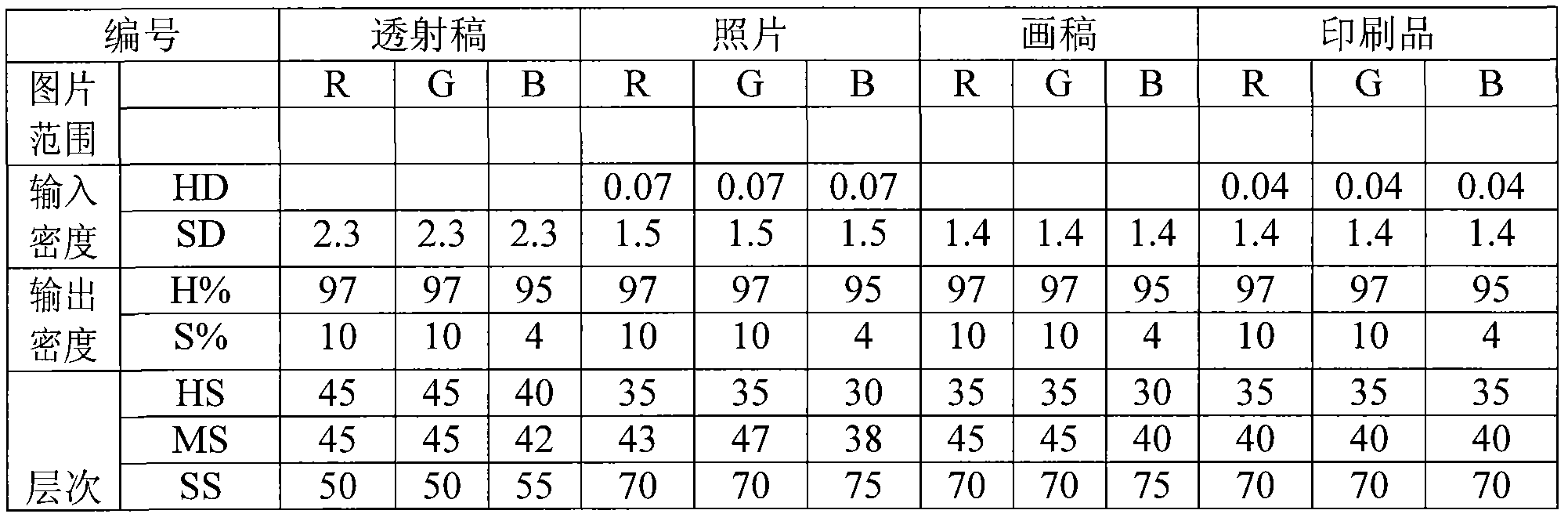

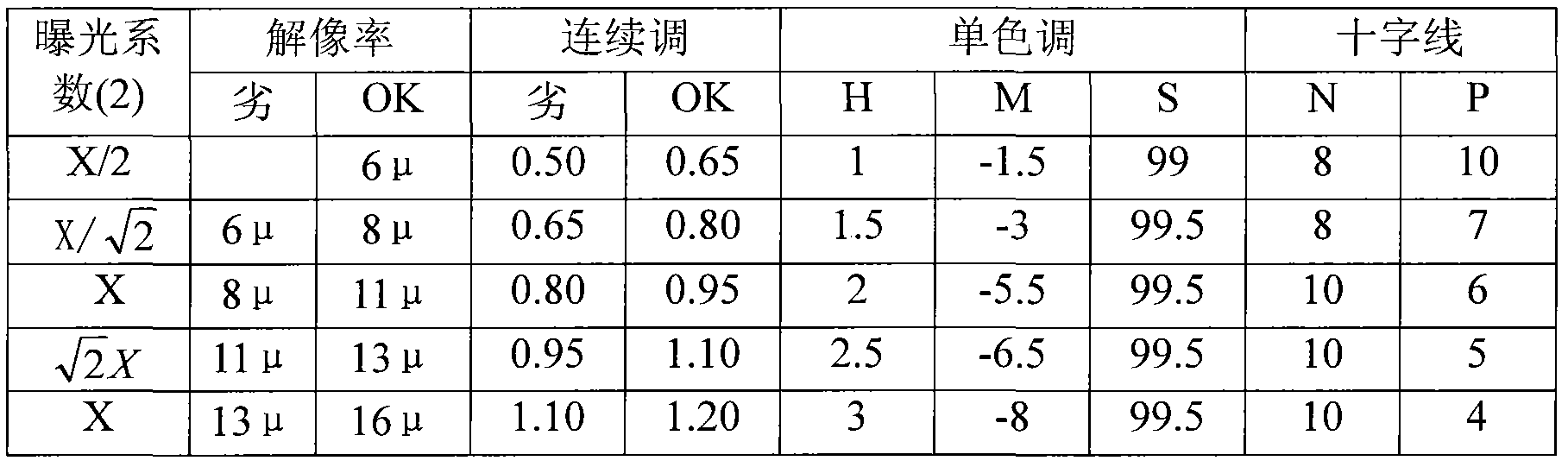

[0016] 1.1 The original color image to be produced is input to the computer through the SG8060 electronic color separation machine, and a 1200dpi TIF electronic file photo is synthesized.

[0017] Input data for transmission drafts, photographs, drawings, and printed matter

[0018]

[0019]

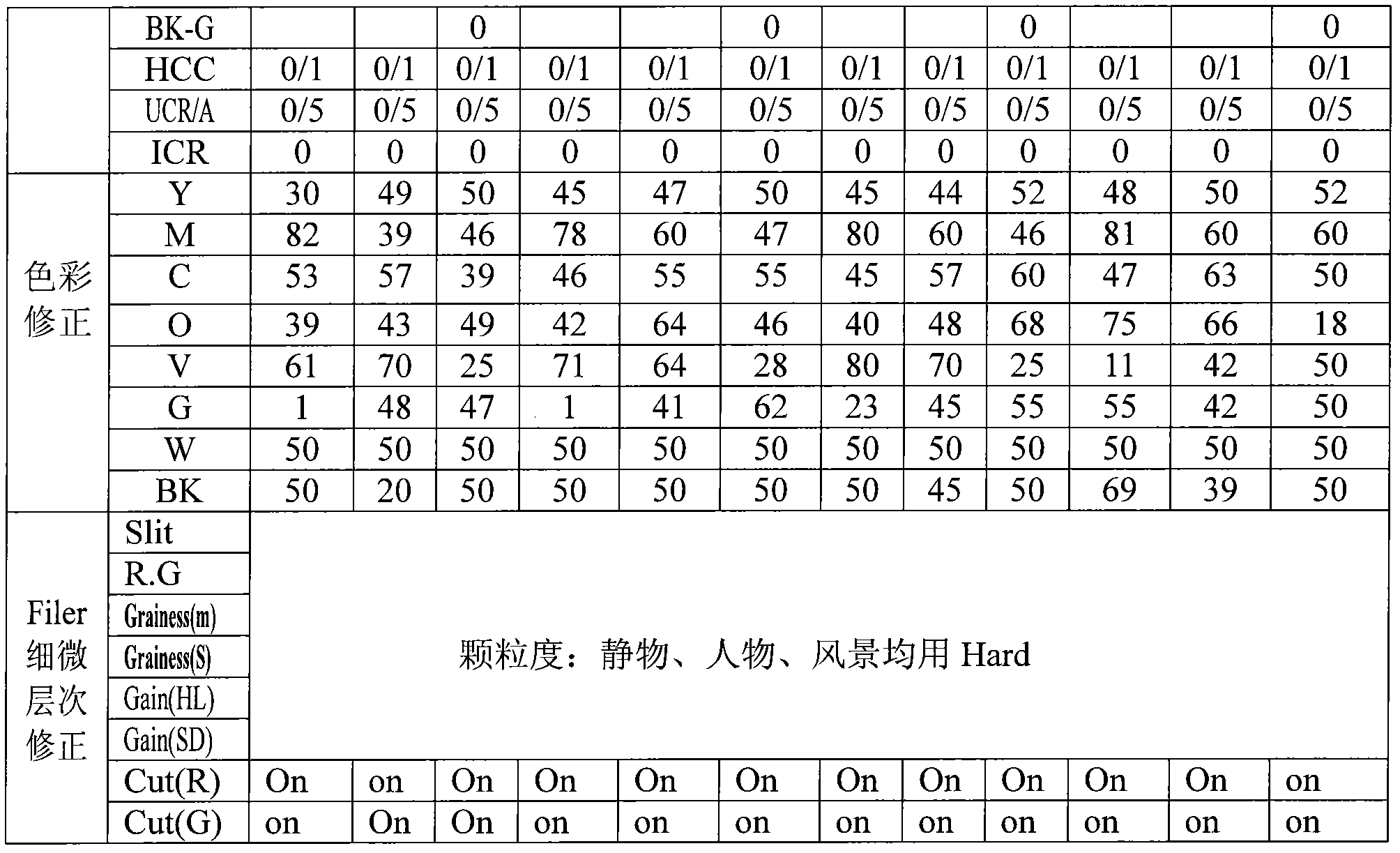

[0020] 2.1 Optimize photos through photoshop color correction technology.

[0021] 1. Layout: Neat: No new dirty spots, white spots, pollution, vignetting (oil bubbles), scratches, creases and other obvious defects.

[0022] 2. Picture:

[0023] Specifications, content, and composition (cutting, direction, front and back) meet the requirements of the layout (printed draft).

[0024] 1) Shade meets the following process requirements:

[0025] target:

[0026] Normal manuscript: coated paper H=Y97% M97% C95% BK125%

[0027] S=Y8% M8% C2% BK15%

[0028] Offset paper H=Y97% M97% C95% BK145%

[0029] S=Y10% M10% C4% BK15%

[0030] Color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com