Wallpaper with corn particle effect and production process of wallpaper

A technology of corn particles and production process, applied in the direction of specific visual effect coating, etc., can solve problems such as single wallpaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

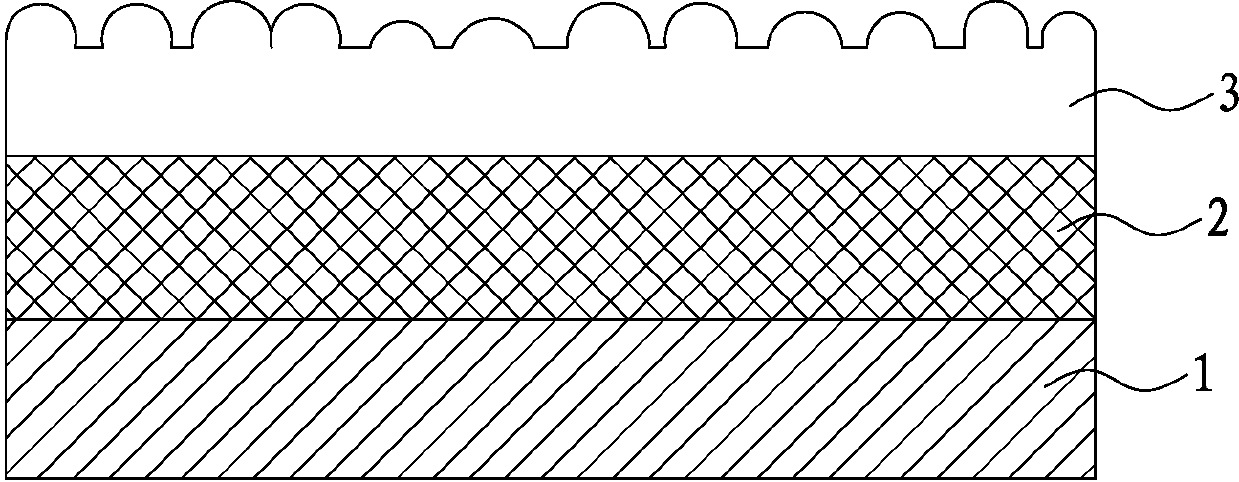

Embodiment 1

[0025] Base paper is used as the base material 1, and a layer of pre-coating liquid slurry is applied on the base material 1 for surface treatment. The pre-coating liquid layer 2 is formed after applying a temperature of 130°C in an oven, and the pre-coating liquid layer 2 is coated with a pattern roller. A layer of slurry, the slurry is composed of the following components by weight percentage: PVC (resin) 50%, DOP19%, TXIB7%, CaCO 3 13%, TiO 2 5%, alkane solvent 2%, chemical foaming agent AC-LC 2 1.5%, ACL-2 1% and stabilizer 1.5%, after the temperature of 155 ℃ is applied in the oven, the temperature of 200 ℃ and 2.5×10 5 After the pressure of Pa, drying, winding, and aging at room temperature, a layer of foaming slurry layer 3 is formed on the precoating liquid layer 2. The foaming slurry layer 3 is concave-convex and has the effect of corn grains.

Embodiment 2

[0027] Use non-woven paper as the base material 1, apply a layer of pre-coating liquid slurry on the base material 1 for surface treatment, wet the surface fibers of the non-woven paper, and form a pre-coating liquid layer 2 after applying a temperature of 120°C in an oven. On the pre-coating liquid layer 2, use a floral roller to coat a layer of slurry, which is composed of the following components by weight percentage: PVC (resin) 45%, DOP22%, TXIB3%, CaCO 3 12%, TiO 2 10%, alkane solvent 4%, chemical foaming agent AC 1%, ACL-2 1.5% and stabilizer 1.5%, after the temperature of 160 ℃ is applied in the oven, the temperature of 200 ℃ and 1.5×10 5 After the pressure of Pa, drying, winding, and aging at room temperature, a layer of foaming slurry layer 3 is formed on the precoating liquid layer 2. The foaming slurry layer 3 is concave-convex and has the effect of corn grains.

Embodiment 3

[0029] Use non-woven paper as the base material 1, apply a layer of pre-coating liquid slurry on the base material 1 for surface treatment, wet the surface fibers of the non-woven paper, and form a pre-coating liquid layer 2 after applying a temperature of 115°C in an oven. On the pre-coating liquid layer 2, use a floral roller to coat a layer of slurry, which is composed of the following components by weight percentage: PVC (resin) 46%, DOP26%, CaCO 3 12%, TiO 2 9%, alkane solvent 2%, chemical foaming agent AC 1.2%, ACL-2 1.8% and stabilizer 2%. 5 After the pressure of Pa, drying, winding, and aging at room temperature, a layer of foaming slurry layer 3 is formed on the precoating liquid layer 2. The foaming slurry layer 3 is concave-convex and has the effect of corn grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com