Positive paste containing carbon nanotube and preparation method and application thereof

A positive electrode slurry and carbon nanotube technology, which is applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of active material slurry agglomeration and uneven dispersion, and achieve the effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

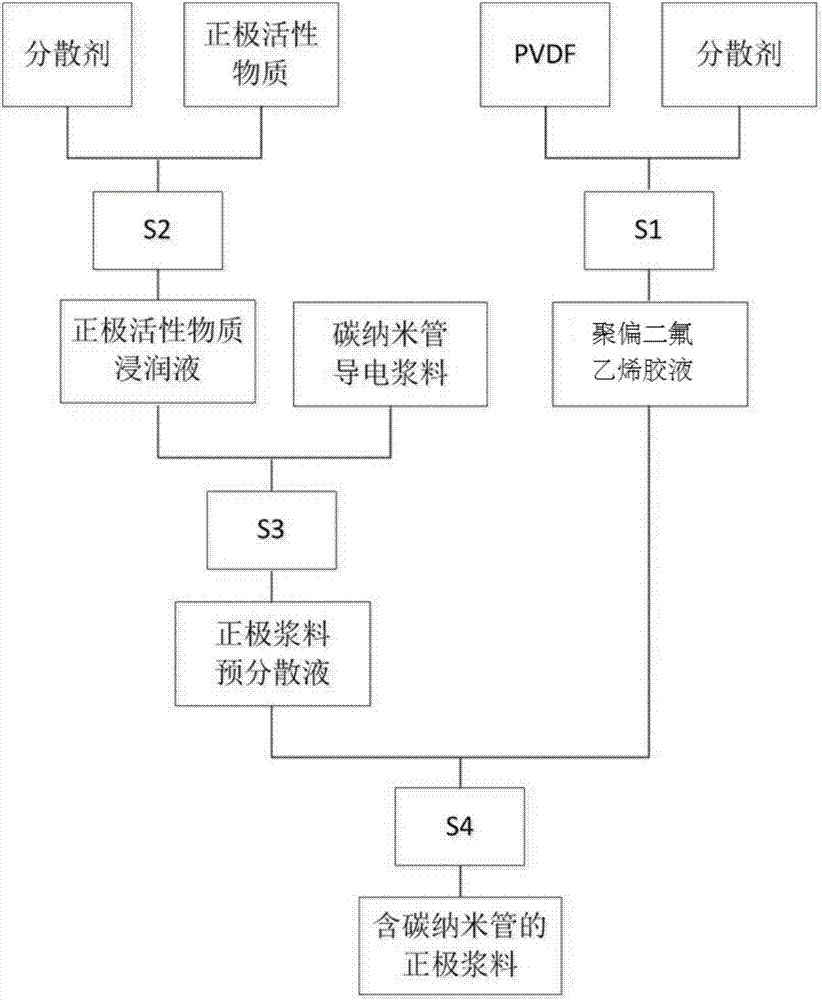

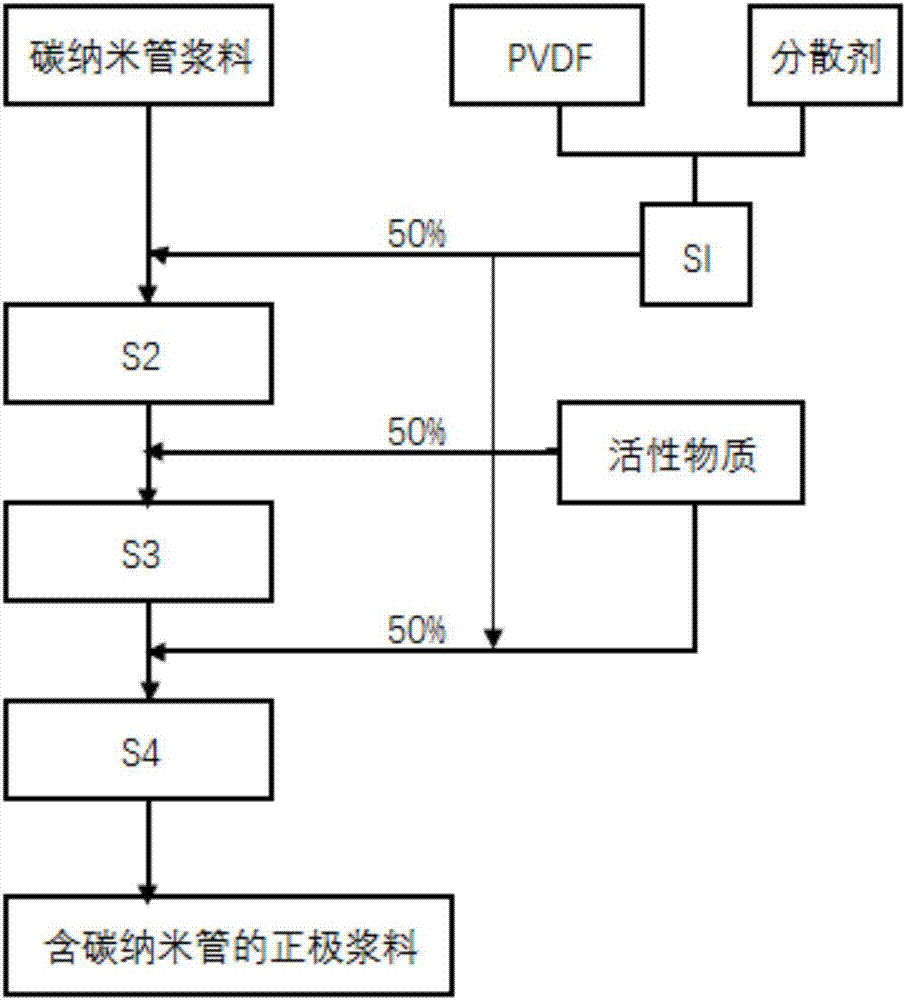

[0057] A method for preparing a uniformly dispersed positive electrode slurry containing carbon nanotubes, comprising the steps of:

[0058] S1. Mix polyvinylidene fluoride resin and N-methylpyrrolidone at a mass ratio of 8:92, stir and disperse to make polyvinylidene fluoride glue; the steps of stirring and dispersing are: first stir at a revolution rate of 10rpm for 3min and then stir for 120min at a rate of 25rpm revolution and 2000rpm dispersion stirring (ie rotation) to achieve the effect of stirring and dispersing.

[0059] S2. According to the mass ratio of the positive active material lithium iron phosphate and N-methylpyrrolidone is 2:1, add the positive active material into N-methylpyrrolidone for infiltration, stir and disperse to obtain the positive active material infiltration solution; stir and disperse The steps are as follows: first stir at a speed of 10 rpm for 3 minutes; then stir for 60 minutes at a speed of 25 rpm and 2000 rpm for dispersion stirring (rotat...

Embodiment 2

[0066] A method for preparing a homogeneously dispersed positive electrode slurry containing carbon nanotubes, comprising the steps of:

[0067] S1. Mix polyvinylidene fluoride resin and N-methylpyrrolidone at a mass ratio of 6:94, stir and disperse to make polyvinylidene fluoride glue; the steps of stirring and dispersing are: first stir at a speed of revolution 15rpm for 5min Then stir for 150min at a rate of 20rpm revolution and 2500rpm dispersion stirring (ie rotation) to achieve the effect of stirring and dispersing.

[0068] S2. According to the mass ratio of the positive active material lithium iron phosphate and N-methylpyrrolidone is 2:1, add the positive active material into N-methylpyrrolidone for infiltration, stir and disperse to obtain the positive active material infiltration solution; stir and disperse The steps are as follows: first stir at a speed of 15 rpm for 5 minutes; then stir for 80 minutes at a speed of 20 rpm and 2500 rpm for dispersion stirring (rota...

Embodiment 3

[0074] A method for preparing a uniformly dispersed positive electrode slurry containing carbon nanotubes, comprising the steps of:

[0075] S1. Mix polyvinylidene fluoride resin and N-methylpyrrolidone at a mass ratio of 10:90, stir and disperse to make polyvinylidene fluoride glue; the steps of stirring and dispersing are: first stir for 4 minutes at a speed of revolution 13rpm and then stir for 130min at a rate of 30rpm revolution and 2300rpm dispersion stirring (ie rotation) to achieve the effect of stirring and dispersing.

[0076] S2. According to the mass ratio of the positive active material lithium iron phosphate and N-methylpyrrolidone is 2:1, add the positive active material into N-methylpyrrolidone for infiltration, stir and disperse to obtain the positive active material infiltration solution; stir and disperse The steps are as follows: first stir at a speed of 13 rpm for 4 minutes; then stir for 70 minutes at a speed of 30 rpm and 2300 rpm for dispersion stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com