PA6/PA56 flow liner silver apparent material and preparation method thereof

A surface, flow pattern technology, applied in the field of engineering plastic alloys, can solve problems such as lack of gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

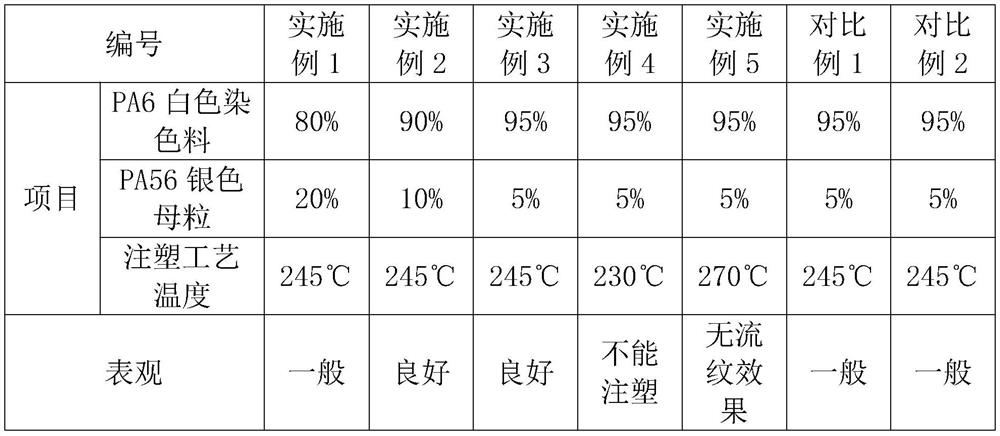

Examples

Embodiment 1

[0043] The preparation method of PA6 / PA56 flow pattern silver appearance material, comprises the following steps:

[0044] (1) Put PA6 Yuehua Chemical YH80095kg, zinc sulfide 0.3kg, zinc sulfide 0.6kg, antioxidant Lianron 10980.2kg, antioxidant Lianron 1680.2kg, lubricant Japan Kao EBFF0.3kg into the twin-screw extruder Perform melt mixing and extrude granulation. The screw length-to-diameter ratio of the twin-screw extruder is 40:1, the screw barrel temperature is 220° C., and the screw speed is 300 rpm to prepare PA6 white dyeing matter.

[0045] (2) Put 5697kg of Cathay biological medium viscose PA5697kg, 0.3kg of silver powder with a particle size of 10μm, 10980.2kg of antioxidant Lianron, 1680.2kg of antioxidant Lianron, and 0.3kg of lubricant Japan Kao EBFF into the twin-screw extruder, The silver powder is side-fed, melt-mixed, and extruded to granulate. The screw length-to-diameter ratio of the twin-screw extruder is 40:1, the screw barrel temperature is 260°C, and the...

Embodiment 2

[0048] The preparation method of PA6 / PA56 flow pattern silver appearance material, comprises the following steps:

[0049] (1) Put PA6 Yuehua Chemical YH80095kg, zinc sulfide 0.3kg, zinc sulfide 0.6kg, antioxidant Lianron 10980.2kg, antioxidant Lianron 1680.2kg, lubricant Japan Kao EBFF0.3kg into the twin-screw extruder Perform melt mixing and extrude granulation. The screw length-to-diameter ratio of the twin-screw extruder is 40:1, the screw barrel temperature is 220° C., and the screw speed is 300 rpm to prepare PA6 white dyeing matter.

[0050](2) Put 5697kg of Cathay biological medium viscose PA5697kg, 0.3kg of silver powder with a particle size of 10μm, 10980.2kg of antioxidant Lianron, 1680.2kg of antioxidant Lianron, and 0.3kg of lubricant Japan Kao EBFF into the twin-screw extruder, The silver powder is side-fed, melt-mixed, and extruded to granulate. The screw length-to-diameter ratio of the twin-screw extruder is 40:1, the screw barrel temperature is 260°C, and the ...

Embodiment 3

[0053] The preparation method of PA6 / PA56 flow pattern silver appearance material, comprises the following steps:

[0054] (1) Put PA6 Yuehua Chemical YH80095kg, zinc sulfide 0.3kg, zinc sulfide 0.6kg, antioxidant Lianron 10980.2kg, antioxidant Lianron 1680.2kg, lubricant Japan Kao EBFF0.3kg into the twin-screw extruder Perform melt mixing and extrude granulation. The screw length-to-diameter ratio of the twin-screw extruder is 40:1, the screw barrel temperature is 220° C., and the screw speed is 300 rpm to prepare PA6 white dyeing matter.

[0055] (2) Put 5697kg of Cathay biological medium viscose PA5697kg, 0.3kg of silver powder with a particle size of 10μm, 10980.2kg of antioxidant Lianron, 1680.2kg of antioxidant Lianron, and 0.3kg of lubricant Japan Kao EBFF into the twin-screw extruder, The silver powder is side-fed, melt-mixed, and extruded to granulate. The screw length-to-diameter ratio of the twin-screw extruder is 40:1, the screw barrel temperature is 260°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com