Dry grain glaze fabric stone imitating brick and preparing method thereof

A dry-grain glaze and cloth technology, which is applied in the direction of manufacturing tools, special patterns, patterns imitating natural patterns, etc., can solve the problems of single decorative effect of tiles and difficulty in imitating natural stone effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

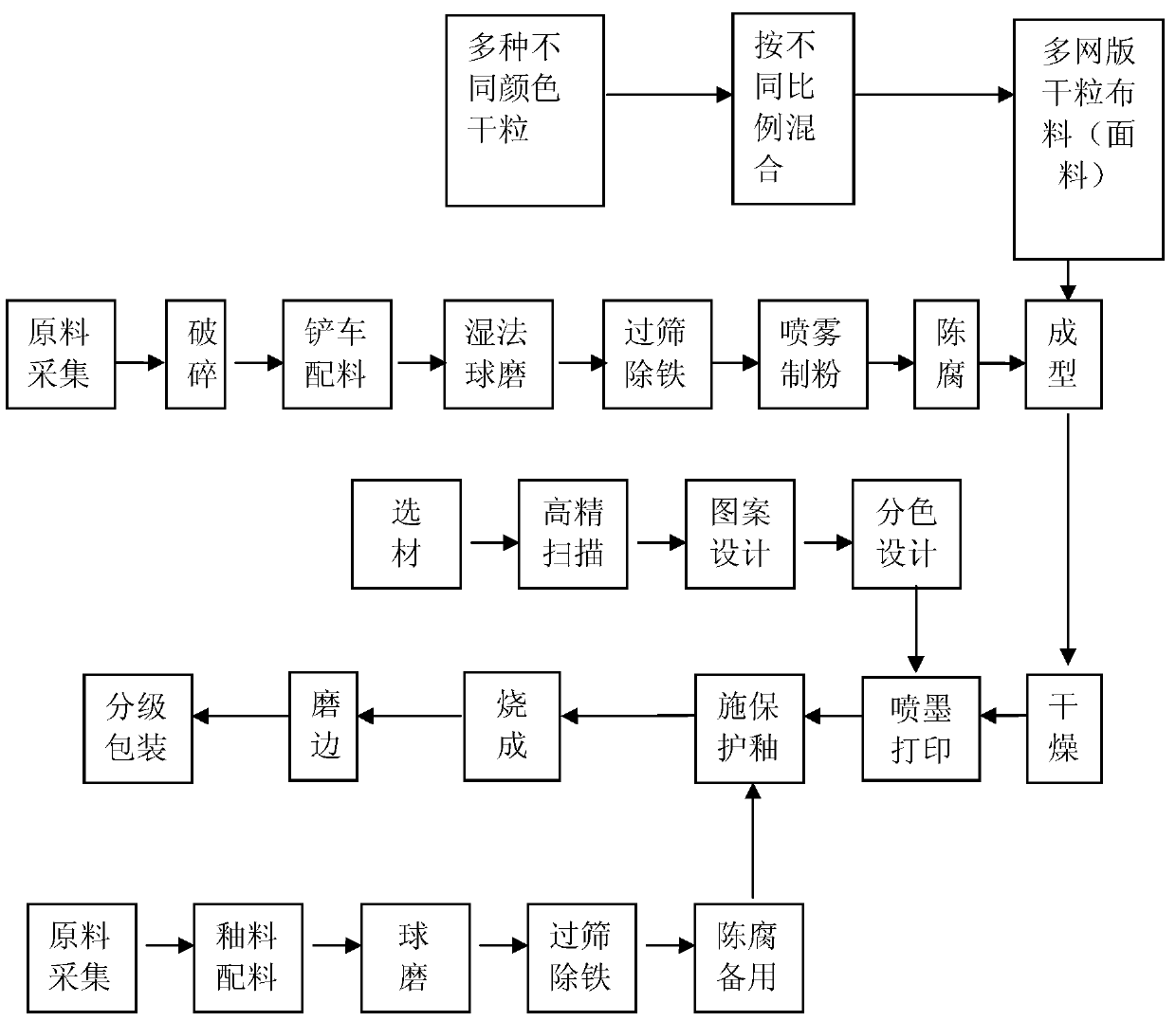

[0063] The preparation method of the billet is not limited, for example, a conventional billet making method can be used. In an example, such as figure 1 As shown, firstly, the raw materials are collected to make the raw materials conform to the formula chemical composition of the billet. Then, the raw materials are crushed, batched by a forklift, wet ball milled, sieved to remove iron, powdered by spraying, and stale to obtain green body powder. Each process parameter in milling can be as follows:

[0064] Mud specific gravity: 1.69~1.71

[0065] Milling fineness: 1~1.2% (250 mesh sieve)

[0066] Particle gradation: 30 mesh above: ≤16%

[0067] 30~60 mesh: ≥70%

[0068] 60~80 mesh: ≤11%

[0069] Under 80 mesh: ≤6%

[0070] Powder moisture: 7.2-7.8%.

[0071] fabric

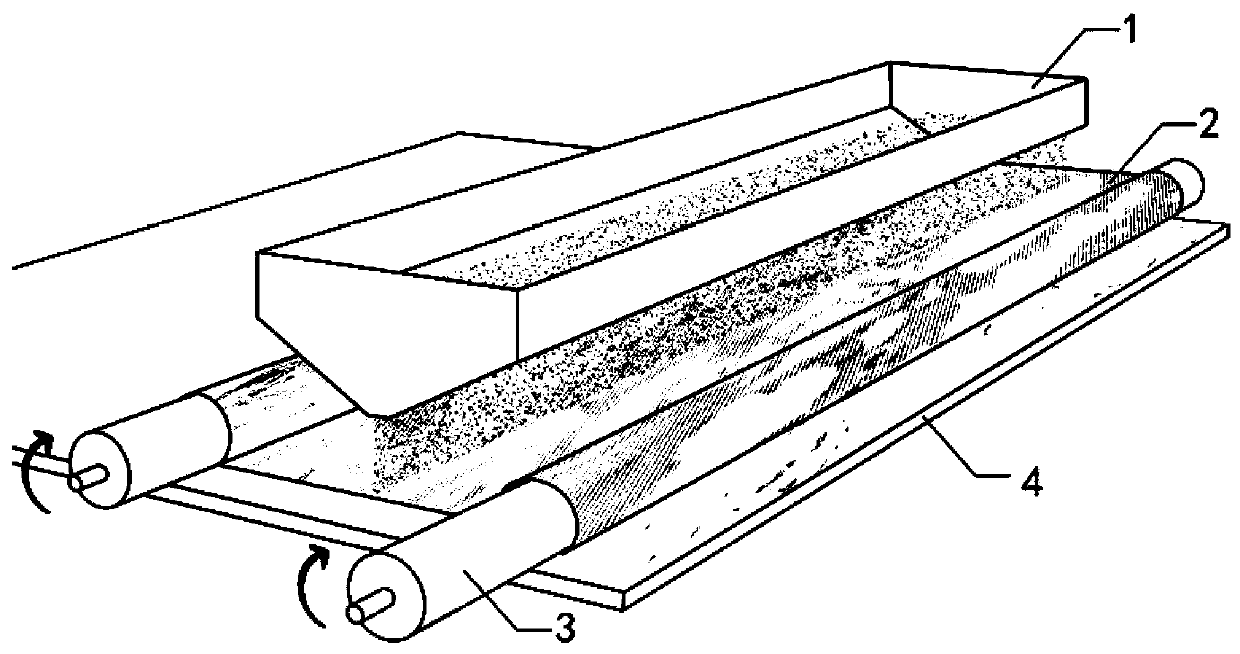

[0072] The blank and the dry granule glaze are distributed, that is, the dry granule is distributed on the blank according to different patterns by using a film. In the present invention, if figure 1 A...

Embodiment 1

[0093] process such as figure 1 shown;

[0094] The process parameters are as follows:

[0095] Billet formula: as shown in the above table 1;

[0096] Dry Grain Glaze Recipe:

[0097]

[0098] Dry glaze: Particle gradation: 30 mesh or more: 0

[0099] 30~60 mesh: 30~37.5%

[0100] 60~80 mesh: 42.5~50%

[0101] 80~100 mesh: 12.5~17.5%

[0102] Under 100 mesh: ≤5%

[0103] The amount of fabric per film (varies according to the pattern):

[0104] Network film: 480~500g

[0105] Pattern film: 100~300g

[0106] Milling process: mud specific gravity: 1.69~1.71

[0107] Milling fineness: 1~1.2% (250 mesh sieve)

[0108] Particle gradation: 30 mesh above: ≤16%

[0109] 30~60 mesh: ≥70%

[0110] 60~80 mesh: ≤11%

[0111] Under 80 mesh: ≤6%

[0112] Powder moisture: 7.2~7.8%

[0113] Molding process: Press machine type: PH3000

[0114] Molding pressure: 360bar

[0115] Press cycle: 3.8 times / min

[0116] Drying process: Drying temperature: 140°C

[0117] Drying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com