Patents

Literature

38 results about "Aesthetic measure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aesthetic Measure. An attempt to bring the basic formal side of art within the purview of simple mathematical formula defining aesthetic measure. Contents: the basic formula; polygonal forms; ornaments and tilings; vases; diatonic chords; diatonic harmony; melody; musical quality in poetry; earlier aesthetic theories; art and aesthetics.

Method for automatic storytelling for photo albums using social network context

InactiveUS20120014560A1Increase weightReduce weightCharacter and pattern recognitionThree levelComputer graphics (images)

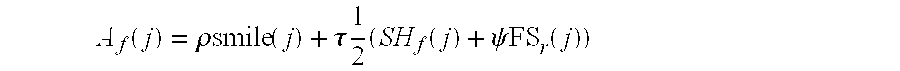

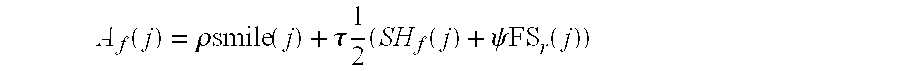

A method for automatically selecting and organizing a subset of photos from a set of photos provided by a user, who has an account on at least one social network providing some context, for creating a summarized photo album with a storytelling structure. The method comprises: arranging the set of photos into a three level hierarchy, acts, scenes and shots; checking whether photos are photos with people or not; obtaining an aesthetic measure of the photos; creating and ranking face clusters; selecting the most aesthetic photo of each face cluster; selecting photos with people until complete a predefined number of photos of the summarized album picking the ones which optimize the function:Of(C,C*,S,CSN)=αfAf(S)−γfd(HCharacter(S)HCharacter(C∪CSN)−δfd(HAct(S), HAct(C*));and then selecting non-people photos which minimize the following function Oa:Oa(C*,S)=d(HAct,(S),HAct(C*));ordering all the selected photos in chronological order; and finally discarding all the photos which have not been selected.

Owner:TELEFONICA SA

Method for automatic storytelling for photo albums using social network context

A method for automatically selecting and organizing a subset of photos from a set of photos provided by a user, who has an account on at least one social network providing some context, for creating a summarized photo album with a storytelling structure. The method comprises: arranging the set of photos into a three level hierarchy, acts, scenes and shots; checking whether photos are photos with people or not; obtaining an aesthetic measure of the photos; creating and ranking face clusters; selecting the most aesthetic photo of each face cluster; selecting photos with people until complete a predefined number of photos of the summarized album picking the ones which optimize the function:Of(C,C*,S,CSN)=αfAf(S)−γfd(HCharacter(S)HCharacter(C∪CSN)−δfd(HAct(S),HAct(C*));and then selecting non-people photos which minimize the following function Oa:Oa(C*,S)=d(HAct,(S),HAct(C*));ordering all the selected photos in chronological order; and finally discarding all the photos which have not been selected.

Owner:TELEFONICA SA

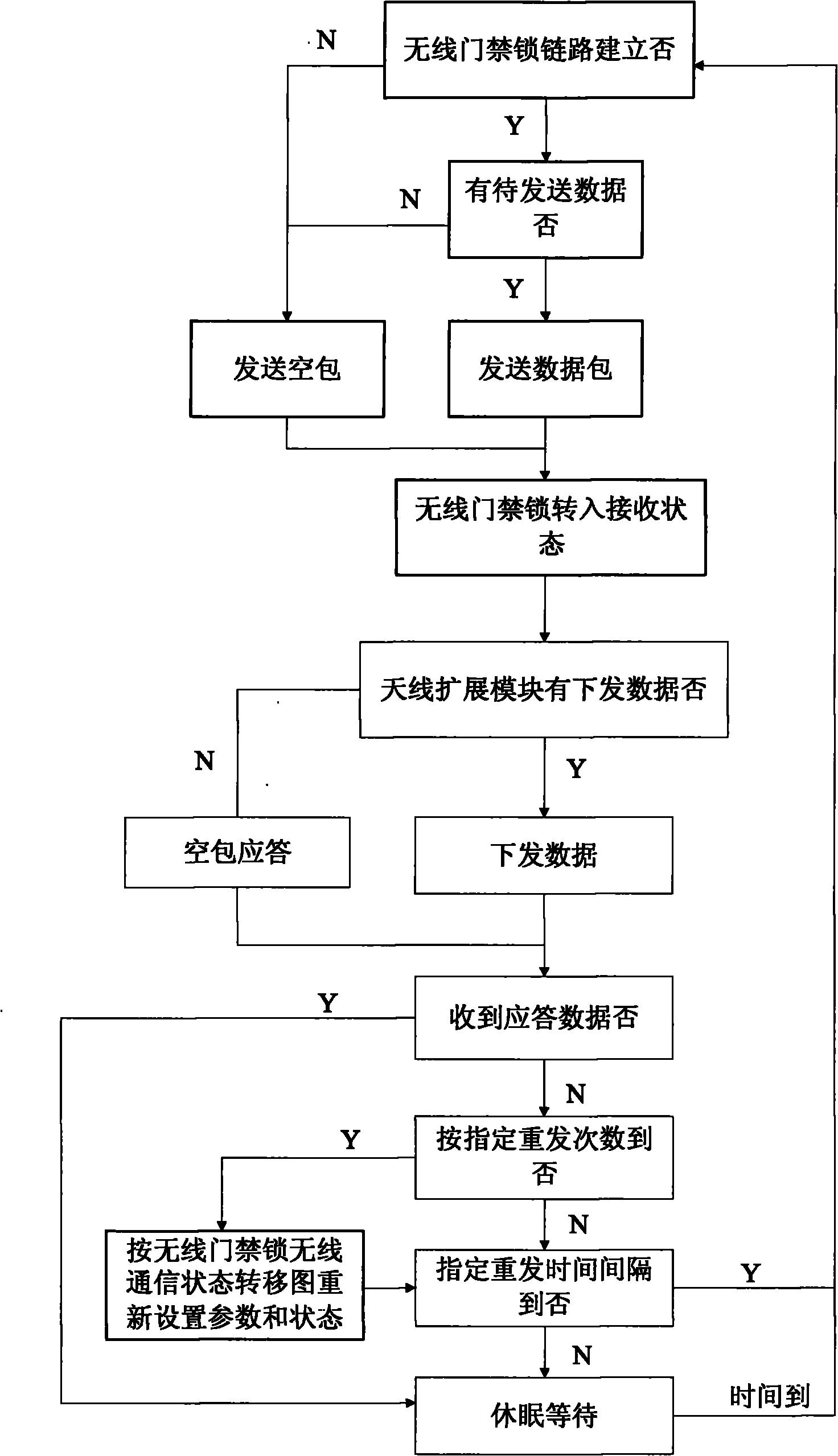

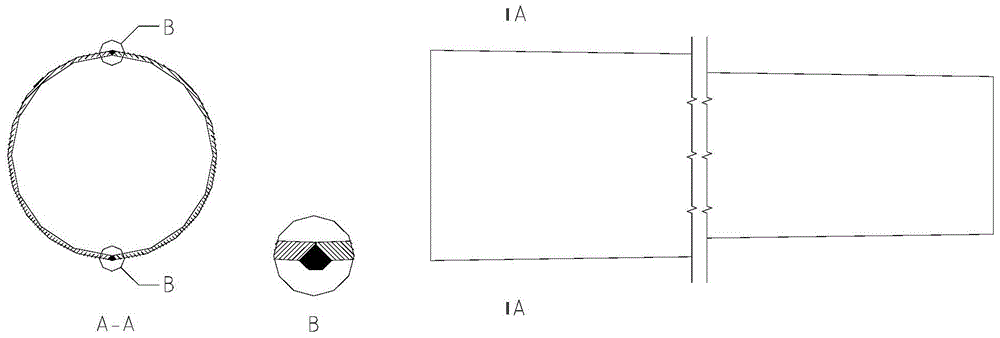

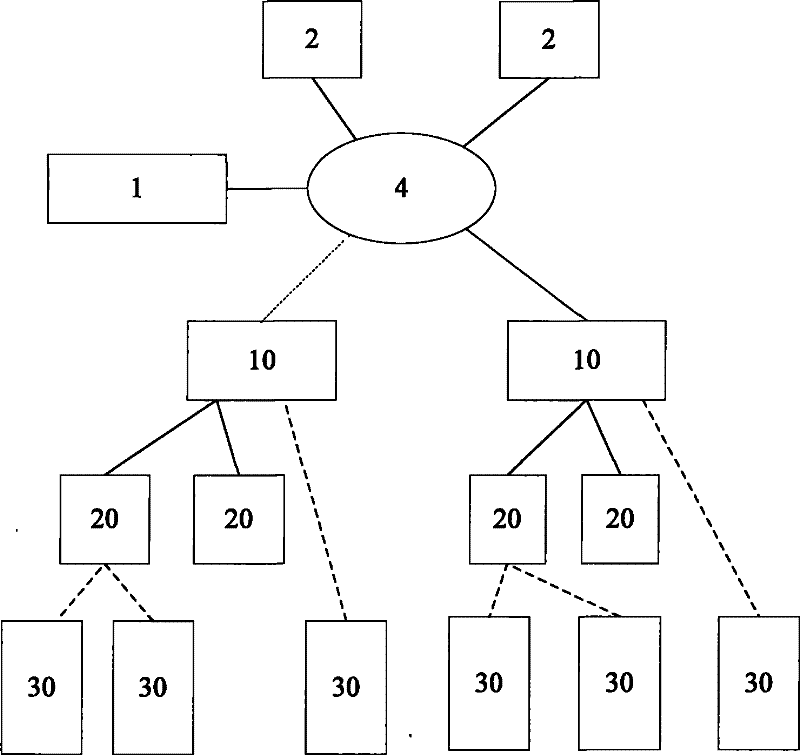

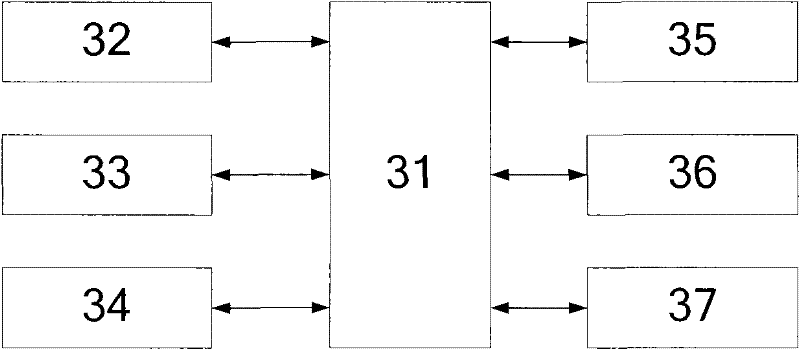

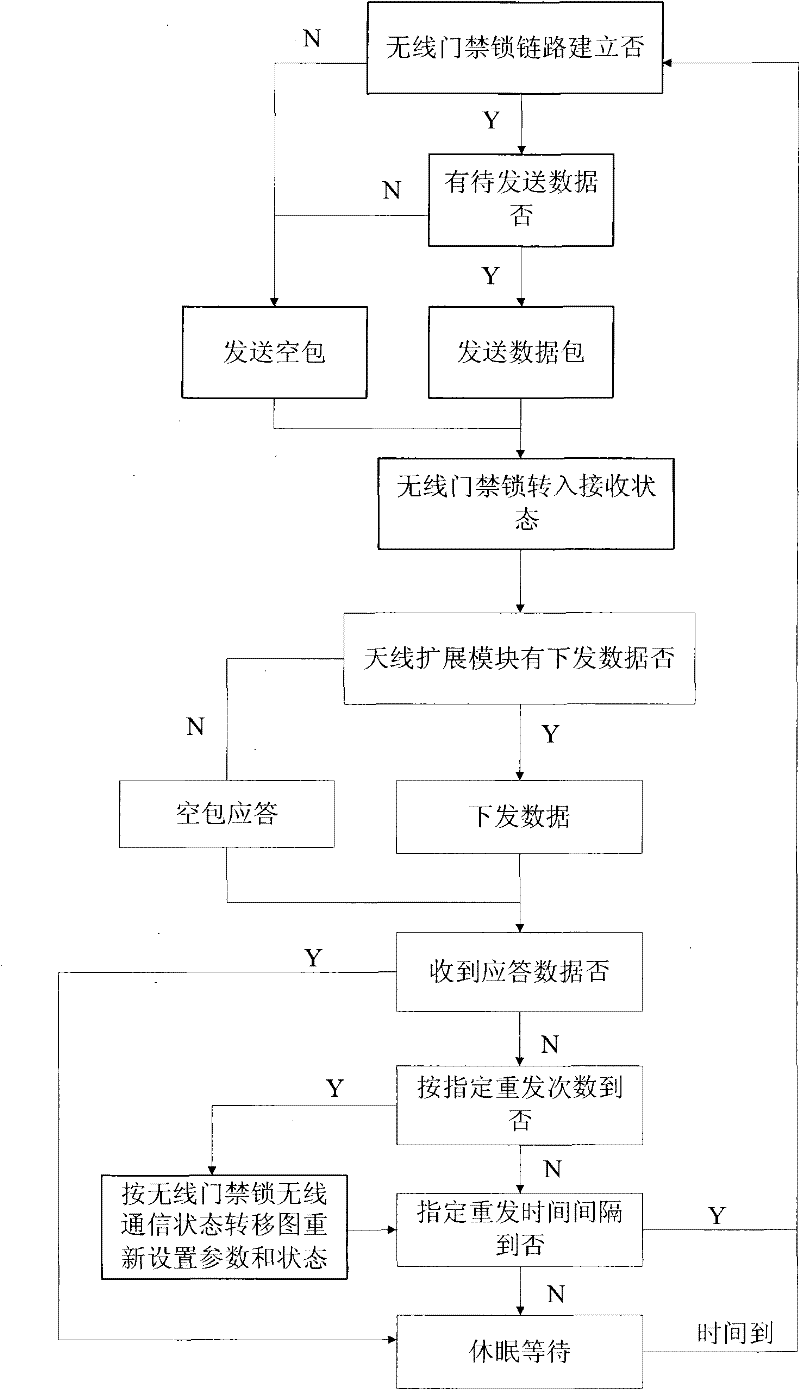

Large real-time wireless networking door control system powered by dry battery

ActiveCN101833802AImprove aestheticsGet rid of the defect of low service lifeData switching by path configurationIndividual entry/exit registersControl systemComputer module

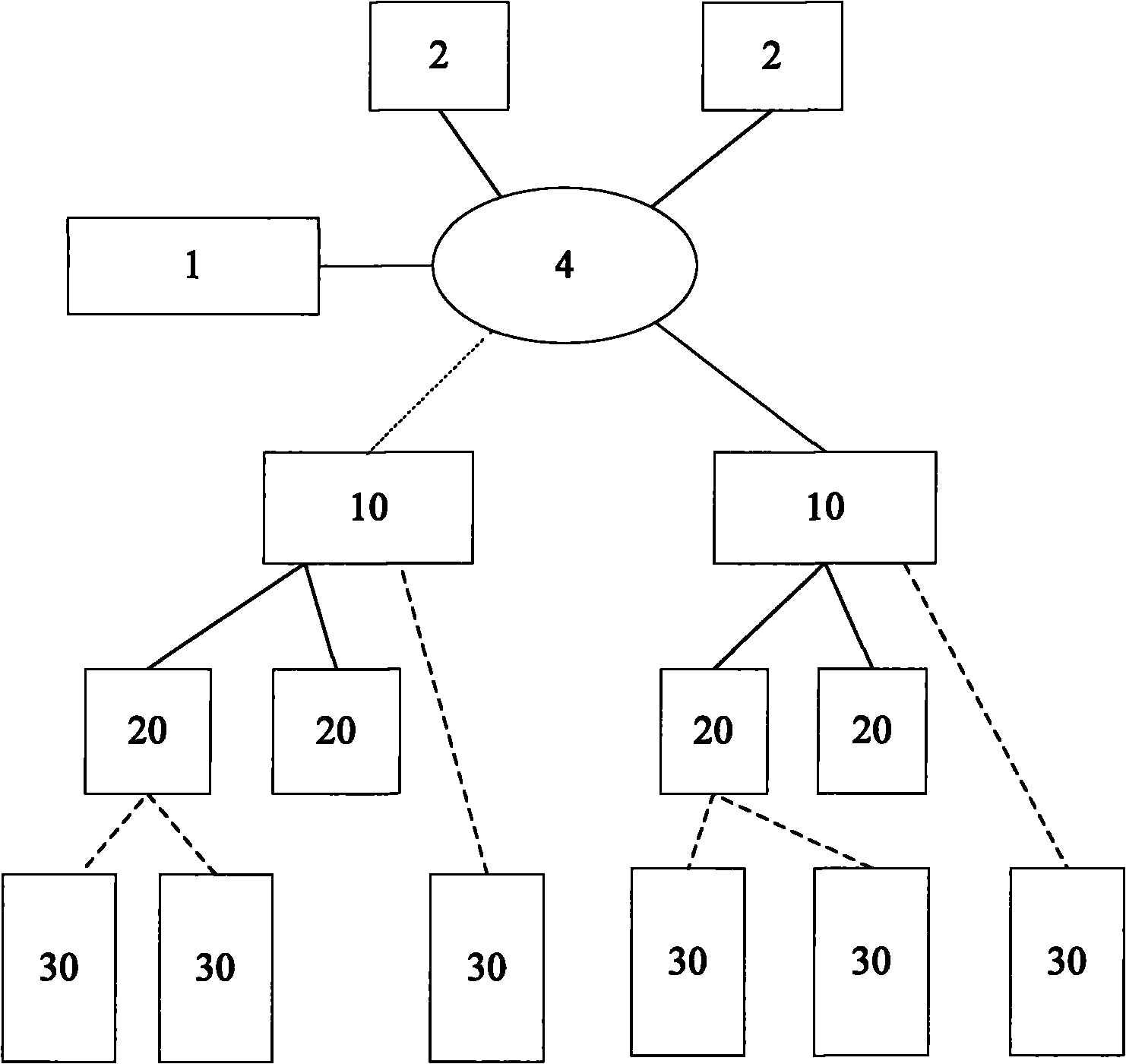

The invention relates to a large real-time wireless networking door control system powered by a dry battery. The present door control system has complicated wiring and large power consumption. The large real-time wireless networking door control system powered by a dry battery comprises a door control management server, a PC client, an LAN (Local Area Network), a master controller, a wireless expansion module and a wireless door control lock, wherein the door control management server, the PC client and the master controller are in signal connection with the LAN, the master controller is in signal connection with the wireless expansion module, and the wireless expansion module is in signal connection with the wireless door control lock. The master controller and the wireless expansion module adopt RS485 communication connection and the wireless expansion module and the wireless door control lock which are in signal connection adopt a control protocol for communication connection. The wireless door control system is driven by the dry battery and no wiring is needed during the installation of the wireless door control management, thereby getting rid of defects that a wired power supply on the door lock reduces the aesthetic measure of the door and the service life is lowered for frequent bending of a power line in the prior art.

Owner:杭州英杰电子有限公司

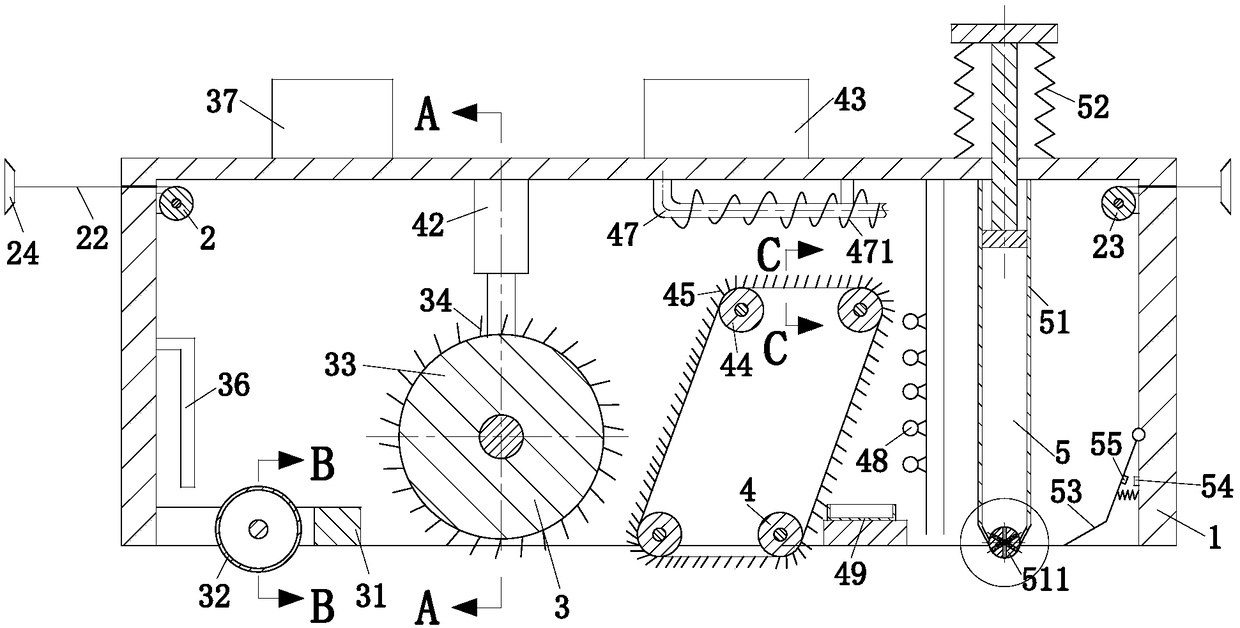

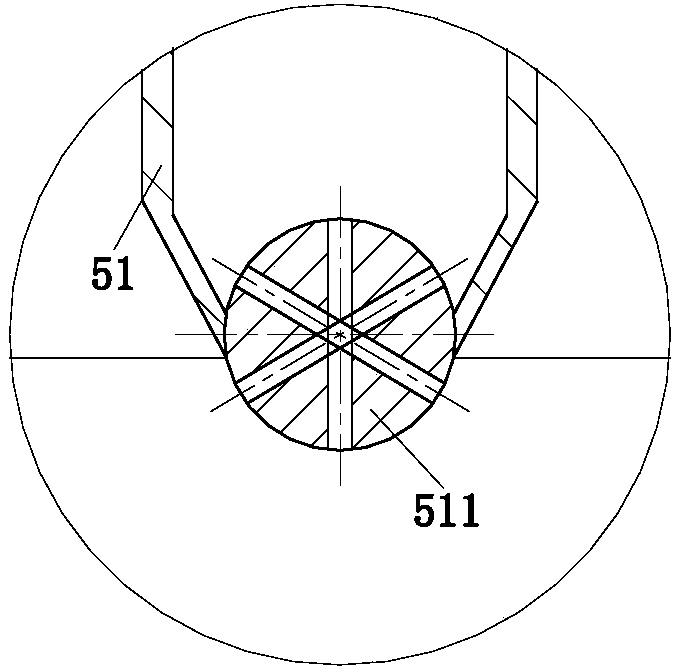

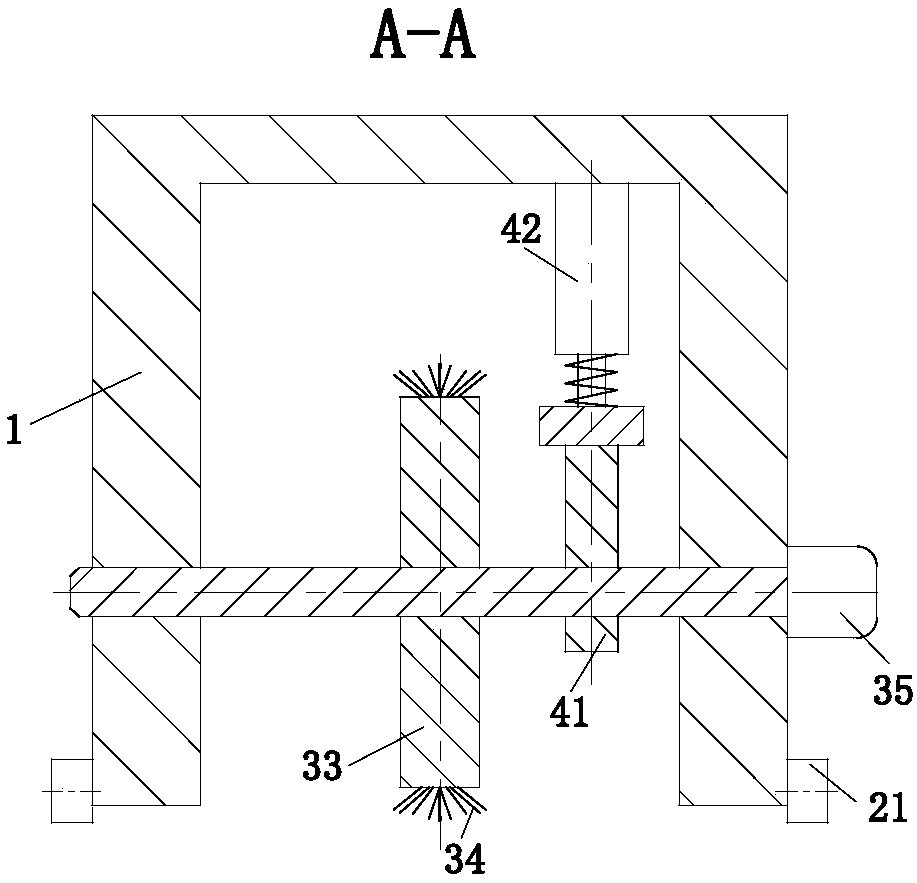

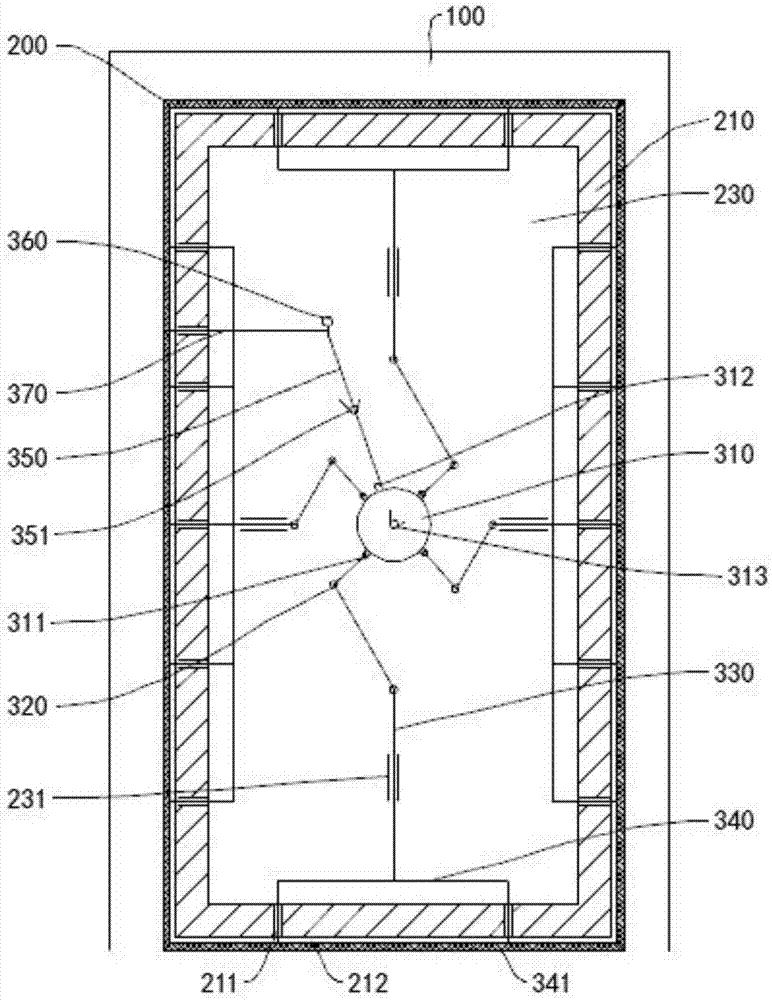

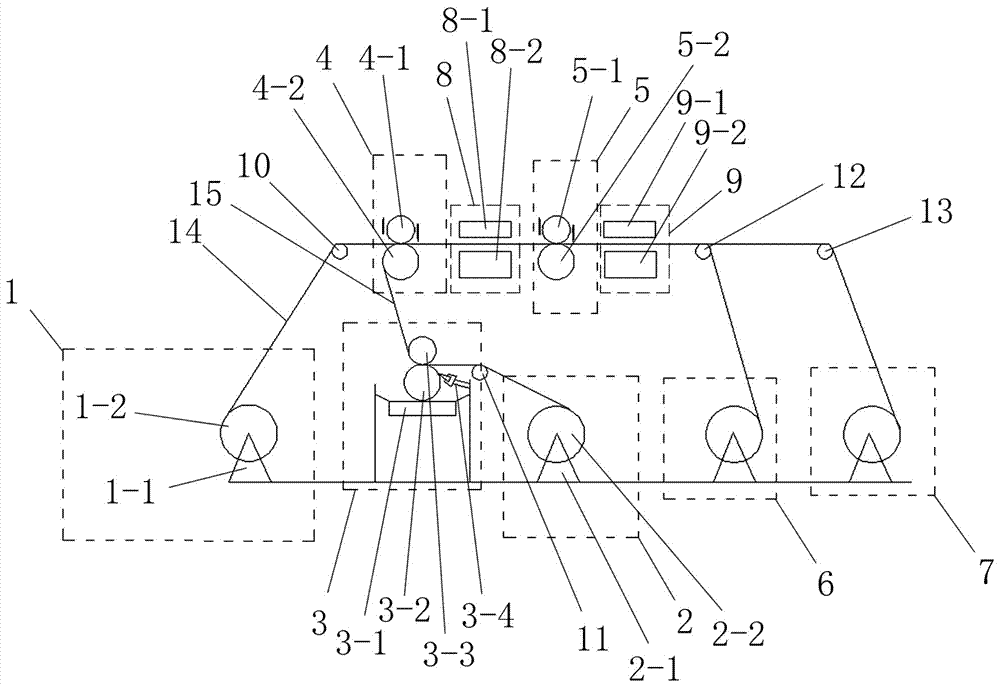

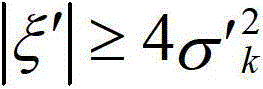

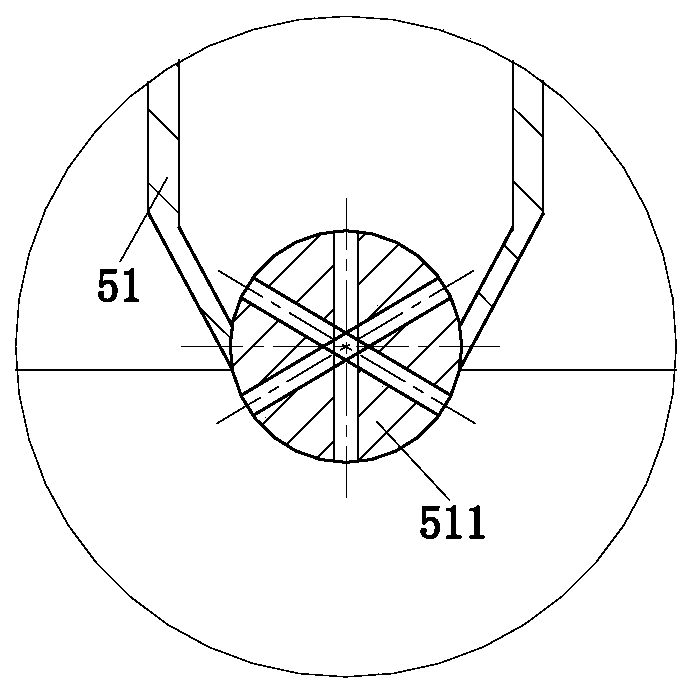

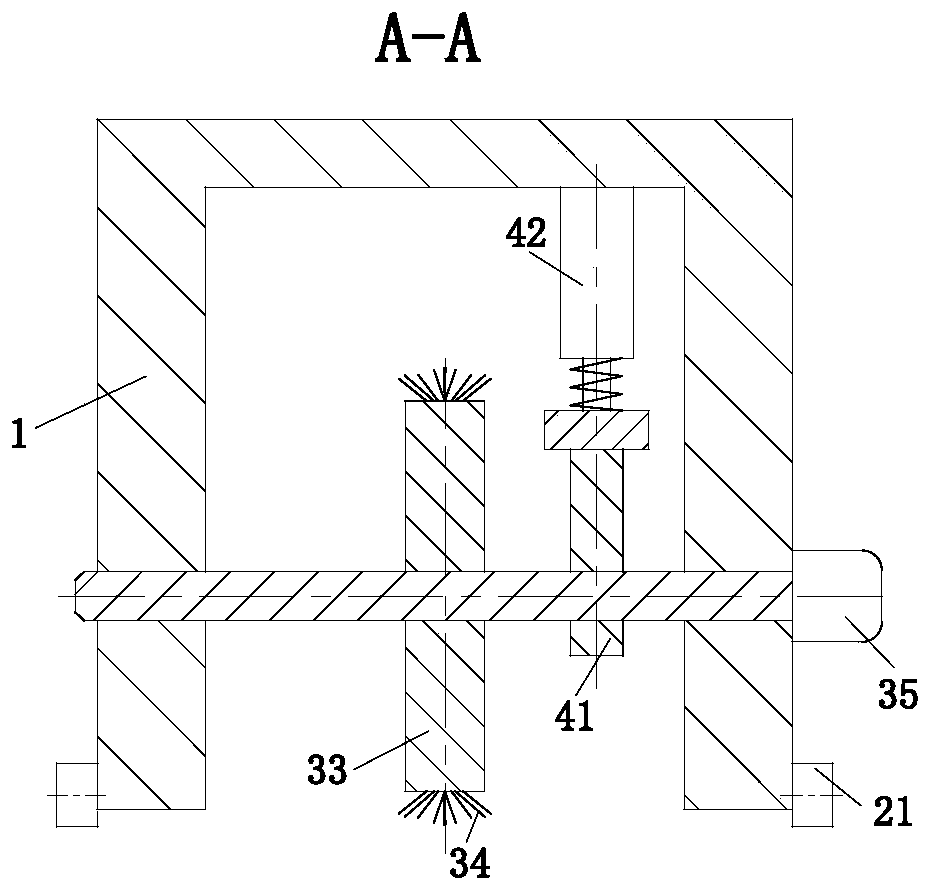

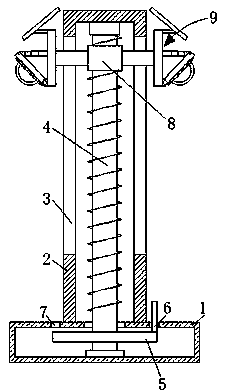

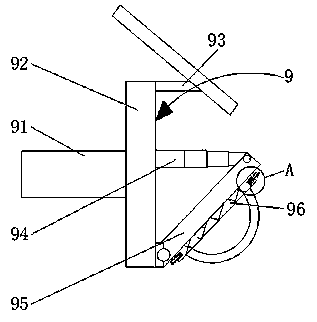

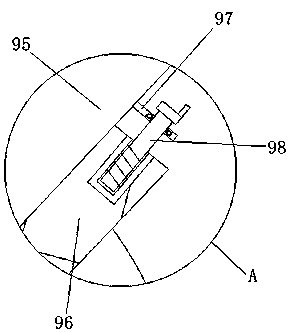

Floor tile joint filling device with automatic gap cleaning function

The invention belongs to the technical field of interior decoration, and particularly discloses a floor tile joint filling device with an automatic gap cleaning function. The floor tile joint fillingdevice comprises a box body, a walking module, a scrubbing module, a wipe-drying module and a joint filling module, and the walking module is used for driving horizontal movement of the box body; thescrubbing module is located inside the box body, and the scrubbing module is used for cleaning stains in gaps of floor tiles and uniformizing the gap width, thereby improving effect and aesthetic measure of joint filling; the wipe-drying module is located at the right side of the scrubbing module, and the wipe-drying module is used for cleaning the stains around the gaps of the floor tiles treatedby the scrubbing module, ensuring a dry environment of the gaps and preparing for the joint filling; and the joint filling module is located at the right side of the wipe-drying module, and the jointfilling module is used for filling a joint filling agent to the gaps cleaned and dried by the wipe-drying module to complete the joint filling work. According to the floor tile joint filling device with the automatic gap cleaning function, the effective cleaning and drying of the gaps of the floor tiles can be realized firstly, and then the treated gaps are subjected to the joint filling work, sothat the work efficiency is high, and the gaps are attractive.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

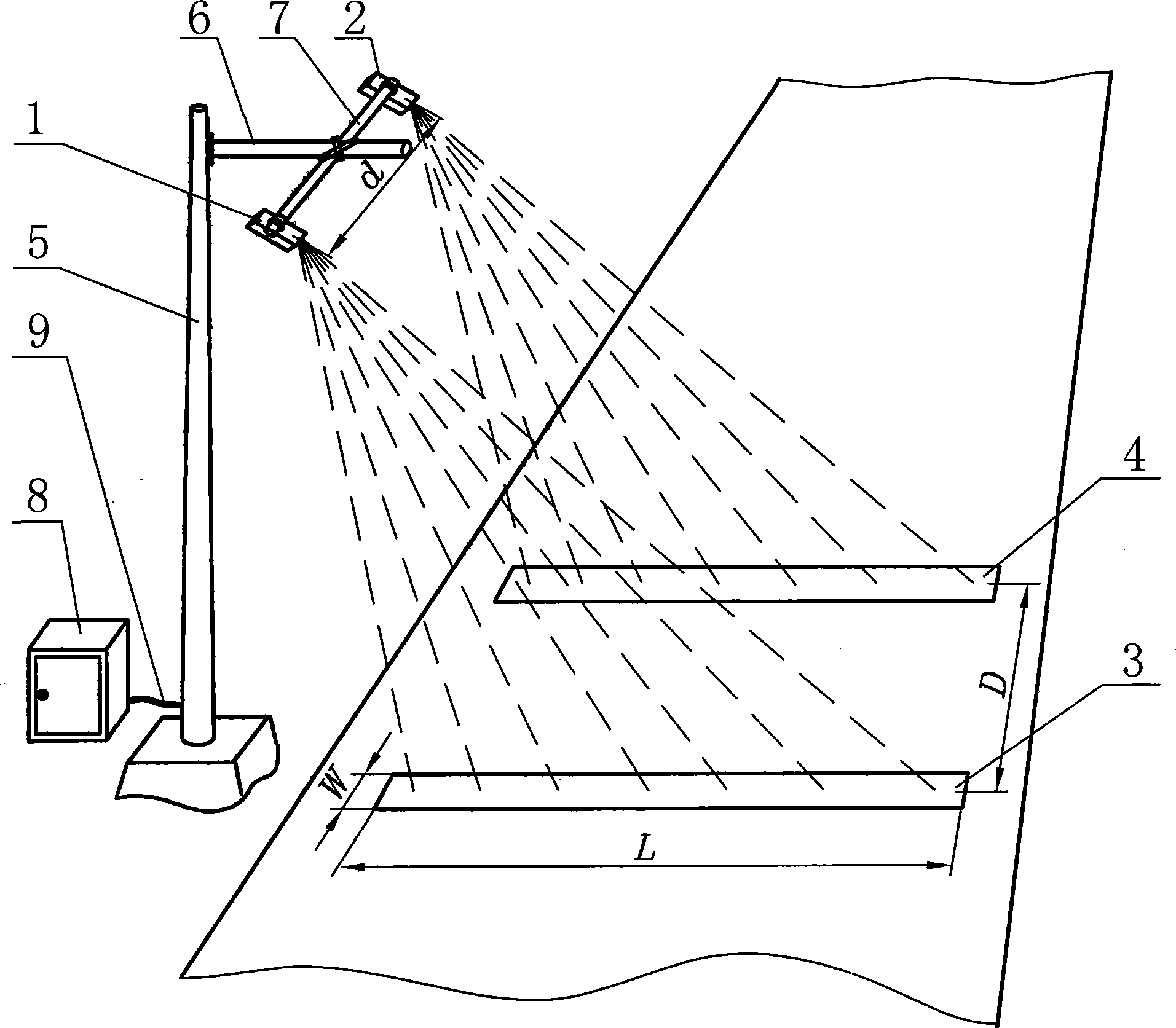

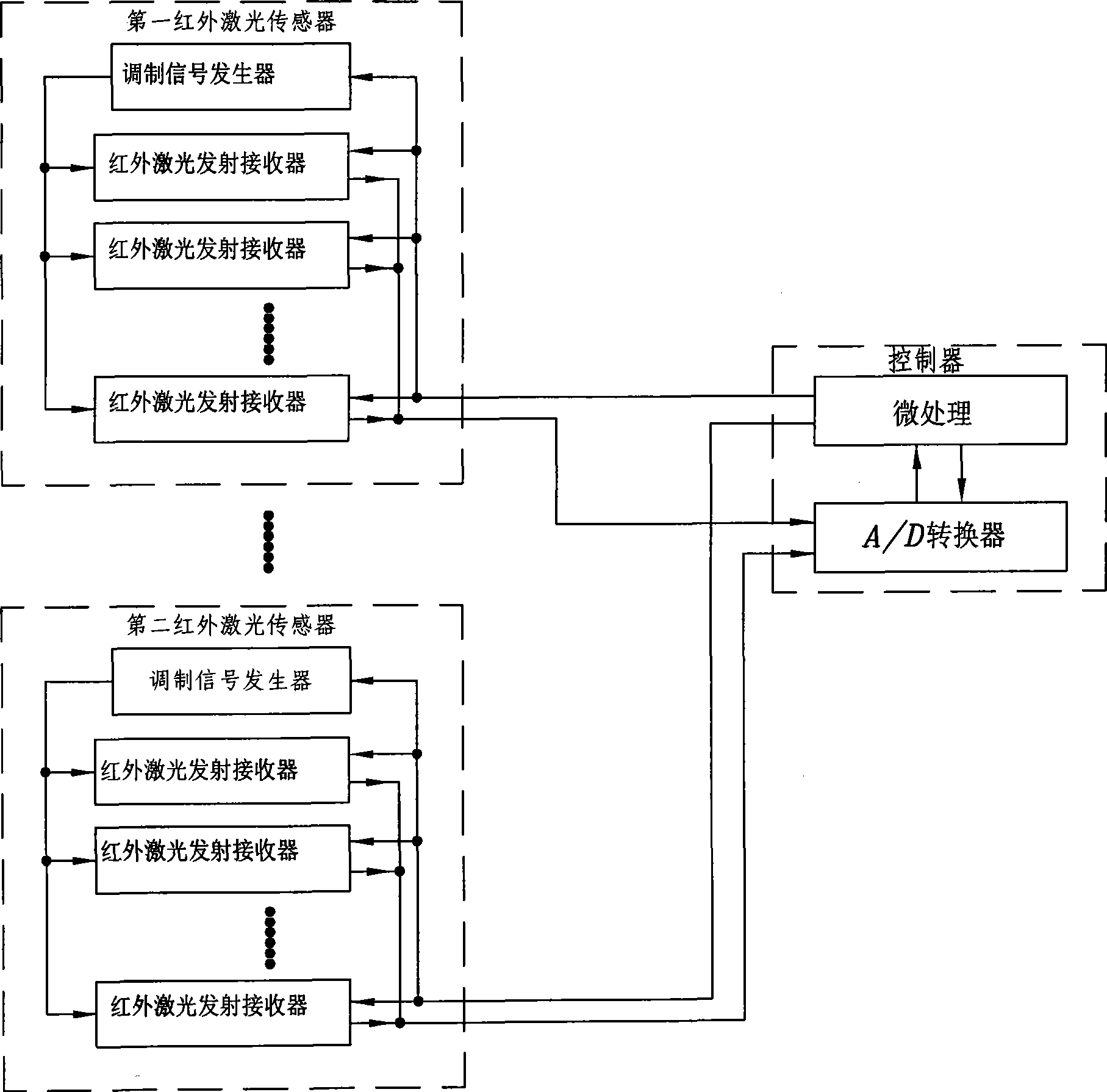

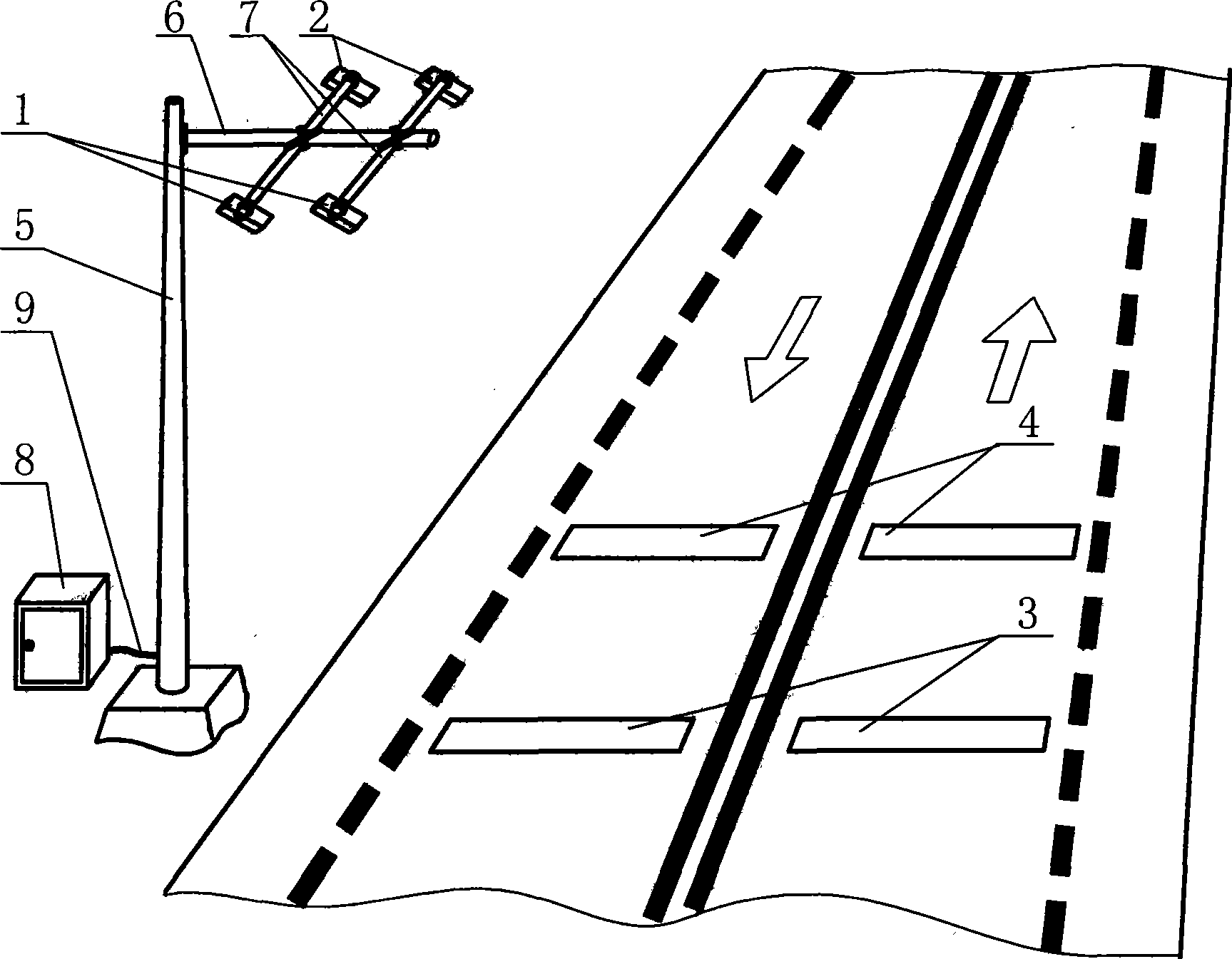

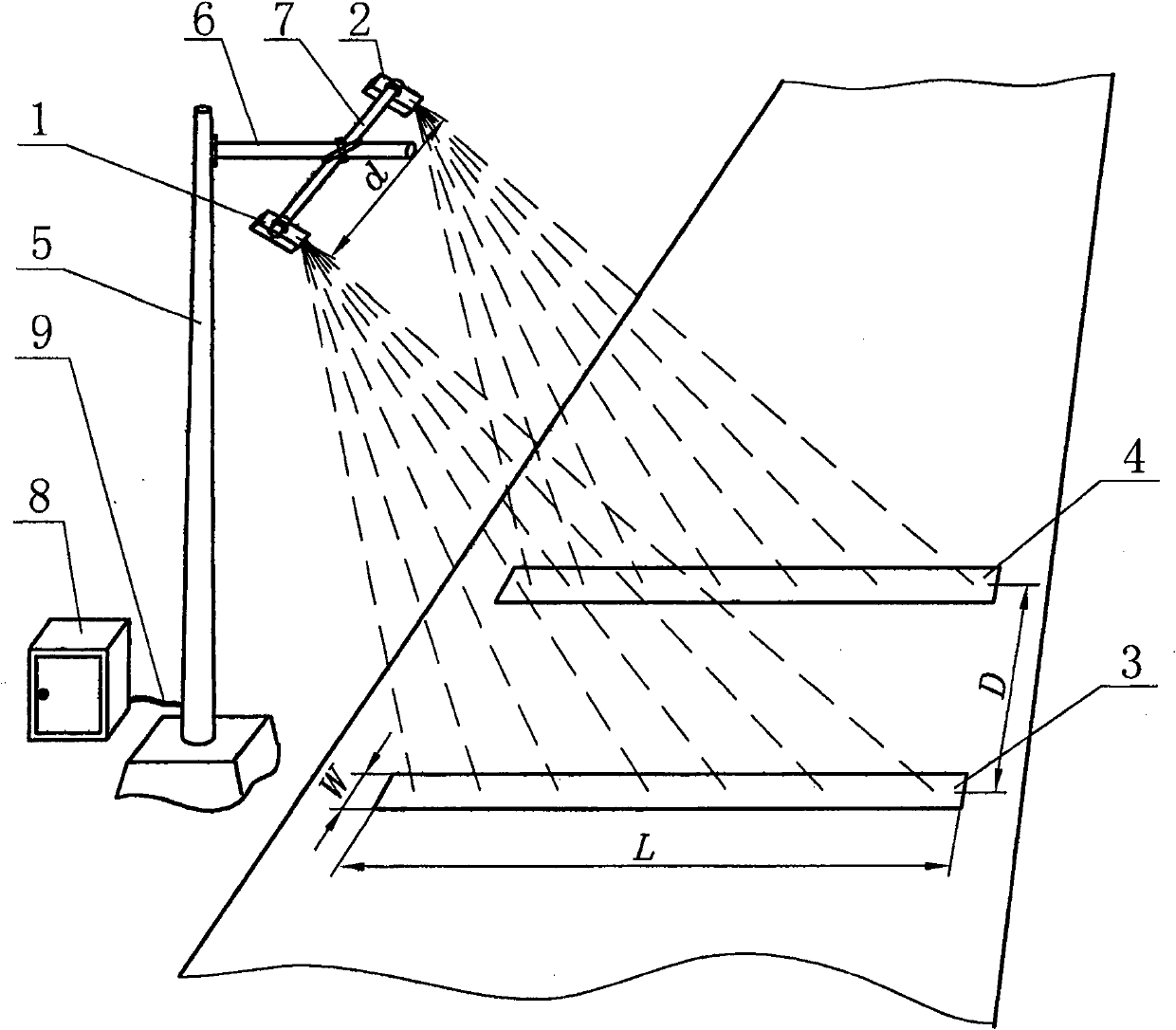

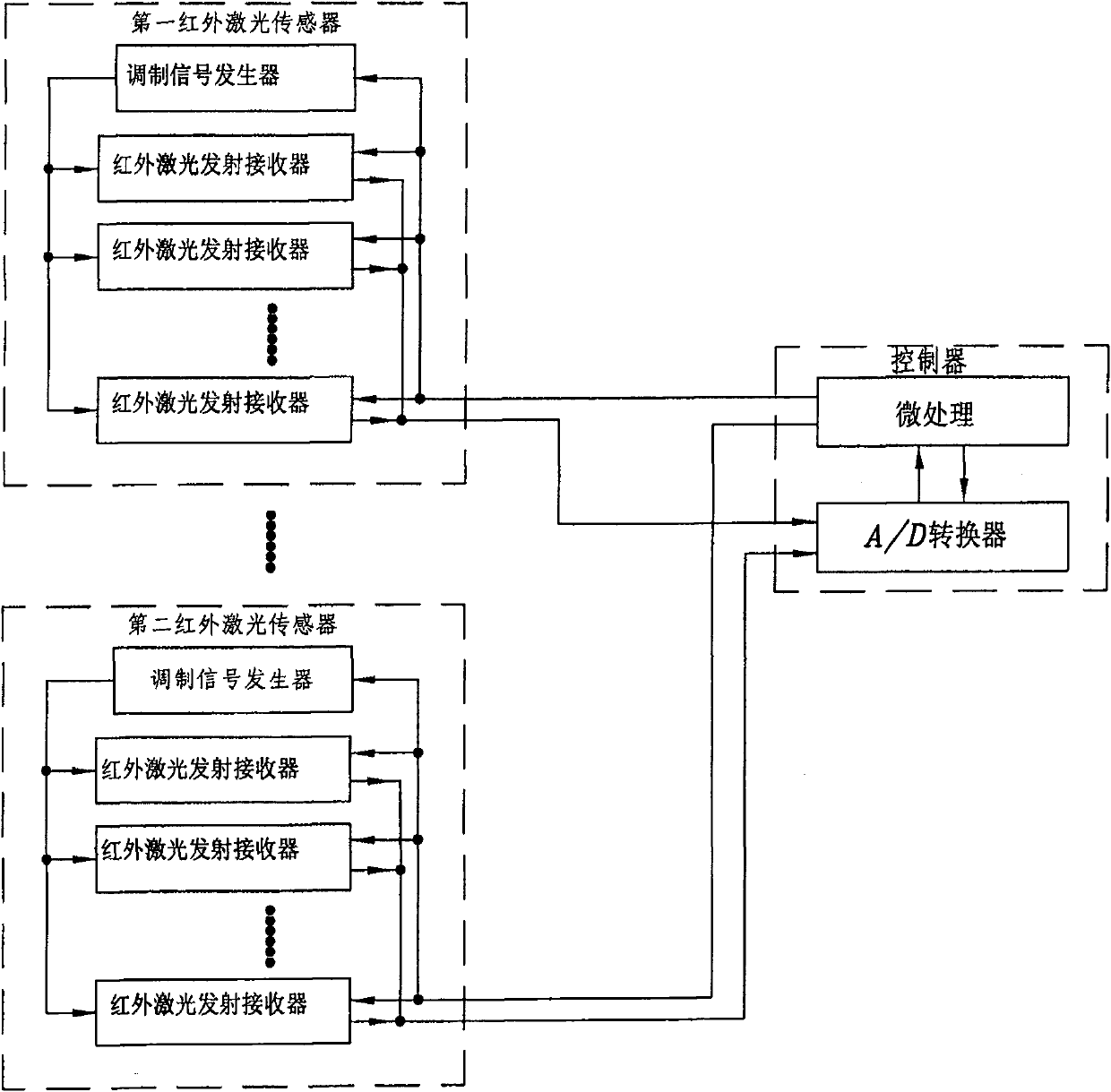

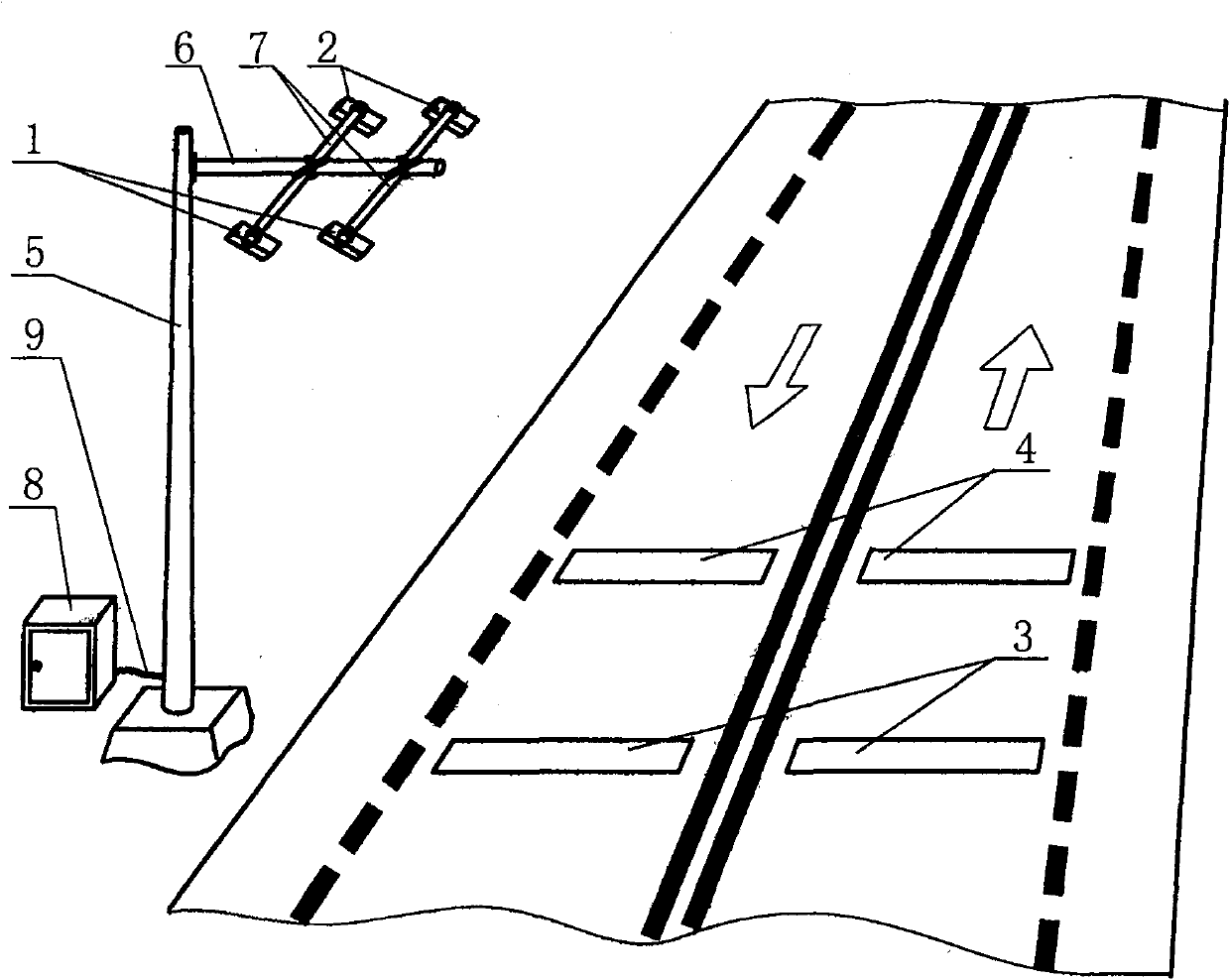

Infrared laser traffic information collecting instrument

InactiveCN101393687ALess aesthetically pleasingWill not missDetection of traffic movementHigh densityLight beam

The invention relates to an infrared laser traffic information collector which comprises a support positioned beside a road, a first infrared laser sensor, a second infrared laser sensor, a controller, a first reflective tape and a second reflective tape; wherein the first infrared laser sensor and the second infrared laser sensor are fixed on a cross bar positioned on the support, and are connected with the controller through cables; The infrared laser traffic information collector has the advantages that the installation is simple, and no portal frame is required to be arranged on the road; the overall cost is low; the influence on the aesthetic measure of the environment is greatly reduced; the collector can be suitable for being distributed in a high density detection station; and the scanning is performed through the light beam of the infrared laser sensors along the width of the traffic lane, so that miss of vehicle detection can not happen.

Owner:ZHONGJIAO YUANZHOU TRAFFIC TECH GROUP +1

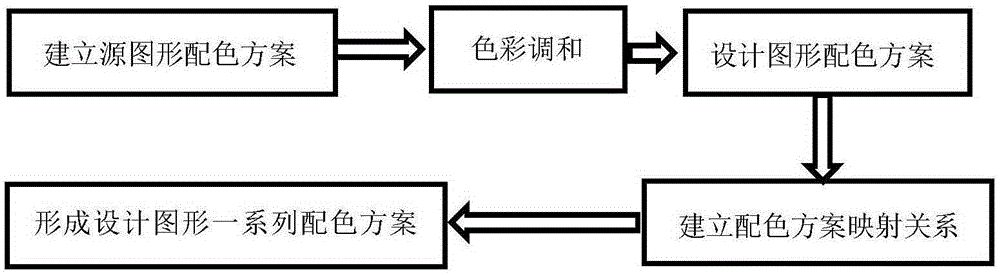

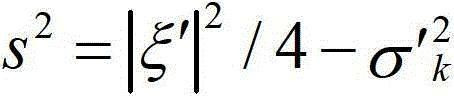

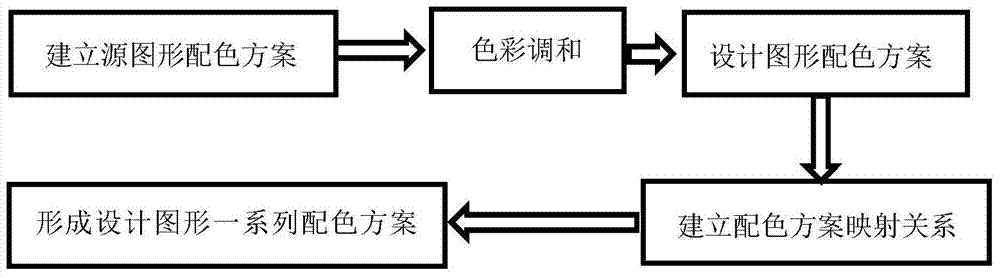

Automated and intelligent figure color-matching method

ActiveCN105303587AReduce labor intensityAvoid Color Extraction BiasImage analysisGraphicsPattern recognition

The invention discloses an automated and intelligent figure color matching method and belongs to the figure design technical field. The method includes the following steps that: representative colors are extracted from a known source figure, color harmonization is performed on the color matching scheme of the source figure, so that the color matching scheme of a designed figure requiring color matching is obtained; and the mapping relationship between the color matching scheme of the source figure and the color matching scheme of the designed figure is established, and representative colors of the designed figure are selected, so that a series of color matching scheme mappings of the designed figure can be formed. With the automated figure intelligent color matching method of the invention adopted, the labor intensity of designers can be reduced, and color matching efficiency can be improved. According to the automated figure intelligent color matching method, aesthetic measures are adopted to measure the quality of the color matching schemes, and therefore, the automated and intelligent figure color matching method is intelligent.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Jewelry sand blasting technology

ActiveCN106363534AImprove processing efficiencyImprove aestheticsPolishing machinesGrinding machinesGranularitySand blasting

The invention discloses a jewelry sand blasting technology which comprises the steps of forming jewelry, carrying out necessary repairing, shaping and deburring on the outer surface of the embryonic form of the jewelry, polishing the finished product and carrying out sand blasting on the finished product, wherein the sand blasting technology comprises the following steps: (1) drawing on a computer and designating corresponding cutting areas on the drawing; (2) according to the drawing data on the computer, cutting the cutting areas on adhesive sticker; (3) pasting the pattern part of the adhesive sticker to the surface of a to-be-processed product; (4) sand blasting: selecting fine powdery diamond sand with proper granularity as required to carry out sand blasting on the embryonic form of the jewelry; and (5) tearing off the adhesive sticker and washing the jewelry. With adoption of the jewelry sand blasting technology, the adhesive sticker pattern is pasted on the surface of a jewelry to finish pattern processing at one time, so that the pattern lathing technology is eliminated; after sand blasting treatment, polishing treatment on the jewelry is not needed, so that the purpose of simplifying the production technology is realized, manpower and material resources are saved, processing efficiency of the jewelry is effectively improved, and the aesthetic measure of the jewelry is greatly improved.

Owner:LAOFENGXIANG DONGGUAN JEWELRY CO LTD

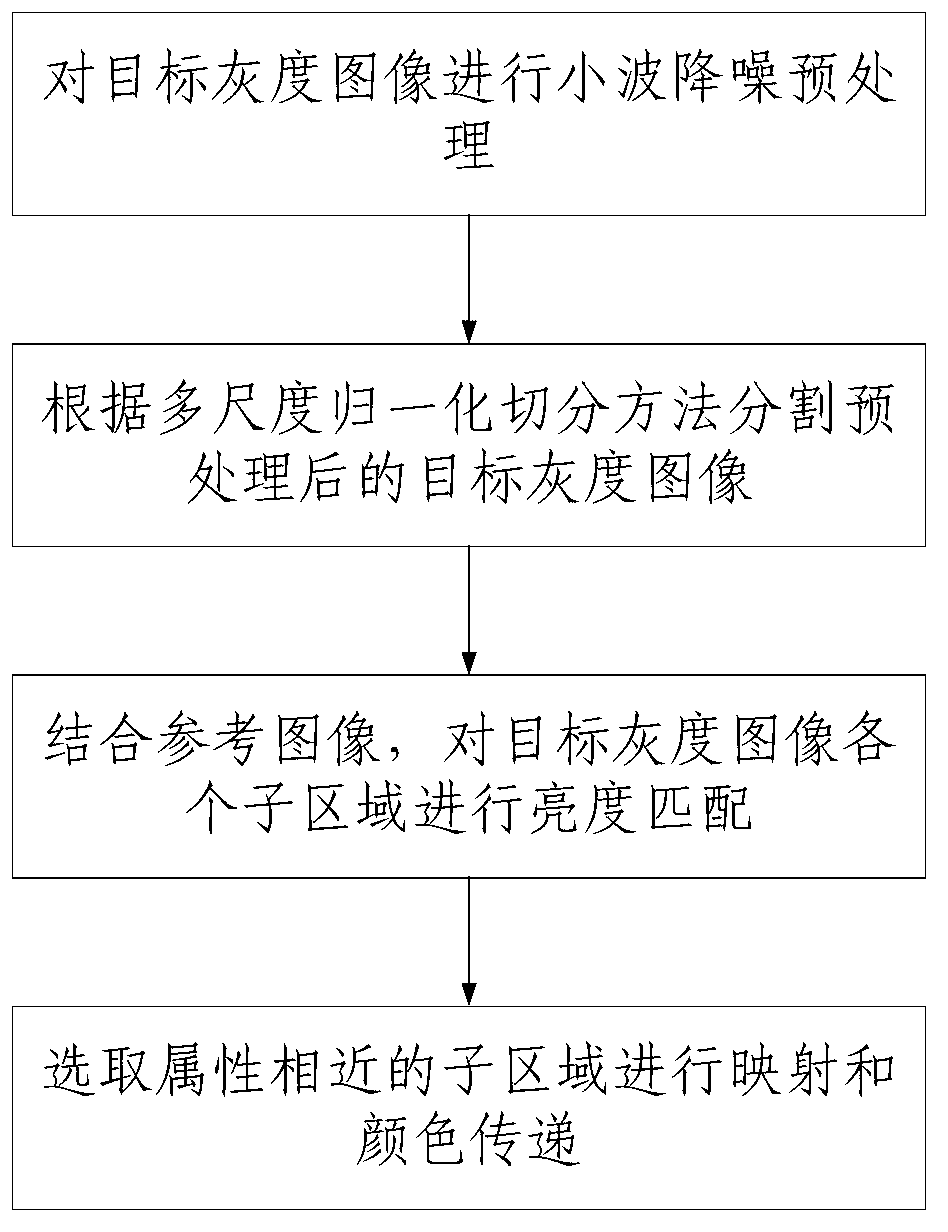

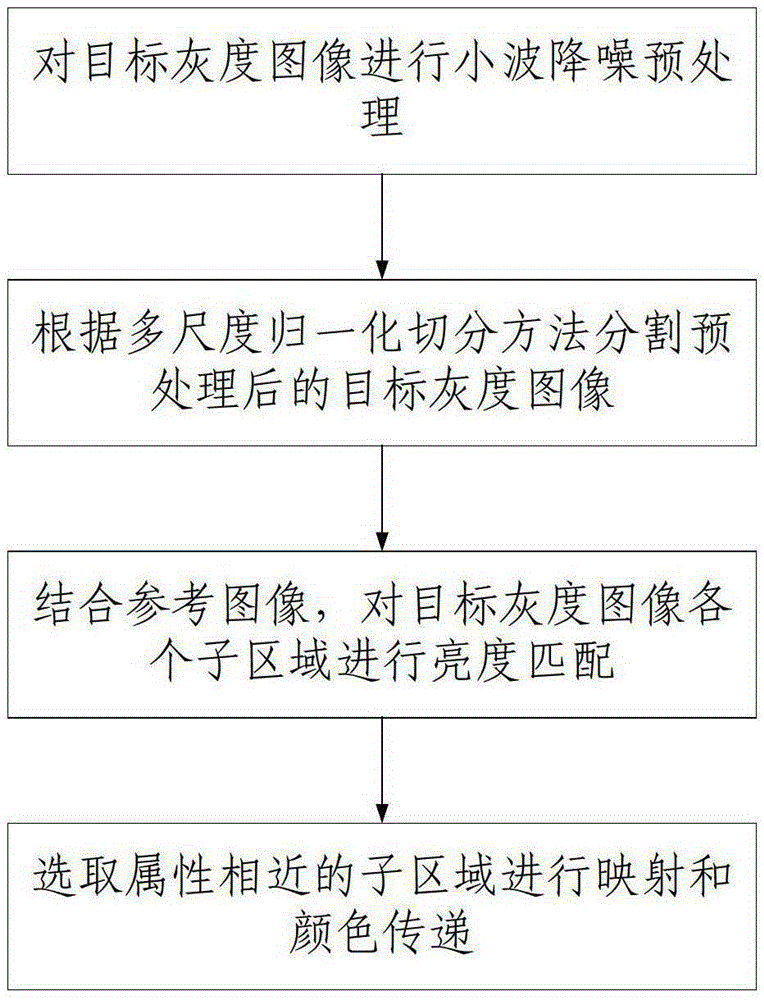

Remote sensing image color enhancing method based on multi-scale image segmentation and color transferring

InactiveCN103136733AImprove legibilityReduce color transfer errorsImage enhancementWavelet denoisingLightness

The invention relates to the technical field of remote sensing image processing, in particular to a remote sensing image color enhancing method based on multi-scale image segmentation and color transferring. The method comprises steps: S1, conducting wavelet denoising preprocessing for a target gray level image; S2, according to a multi-scale normalized segmentation method, conducting segmentation of the target gray level image after preprocessed; S3, combining a reference image, and conducting brightness matching for all sub-domains of the target gray level image; and S4, selecting a sub-domain with the similar property to conduct mapping and color transferring. Aesthetic measure and target recognized degree of a result image are obviously enhanced, under the condition that image registering is not needed, the method can achieve full-automatic color enhancing for a remote sensing image which is relatively simple in texture structure and big in brightness contrast just through a color reference image which is similar in character and style, and therefore, the remote sensing image color enhancing method provides strong technical support for remote sensing image processing.

Owner:NO 61 INST OF GENERAL STAFF +1

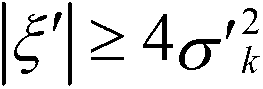

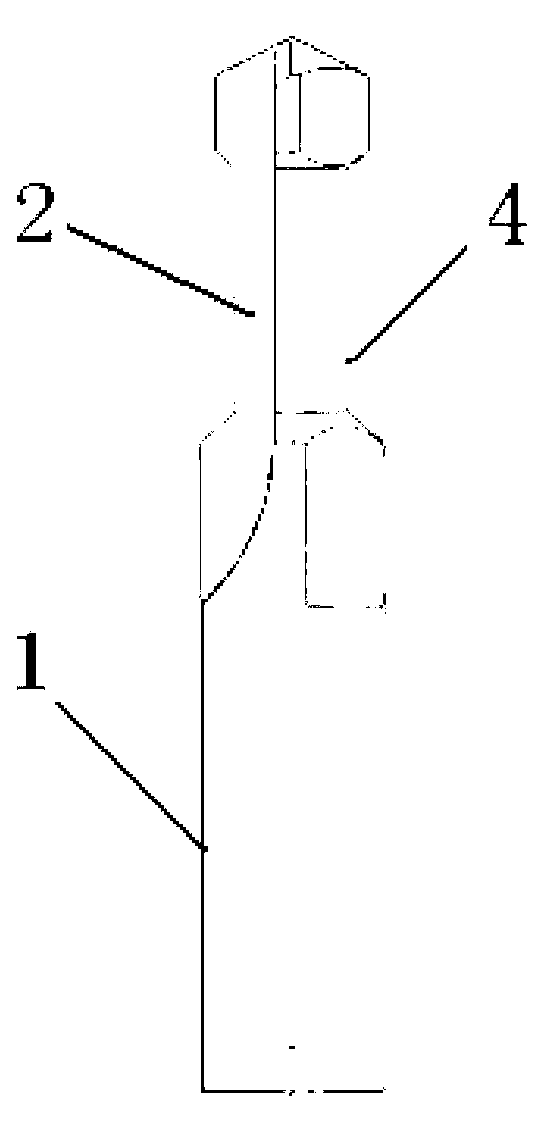

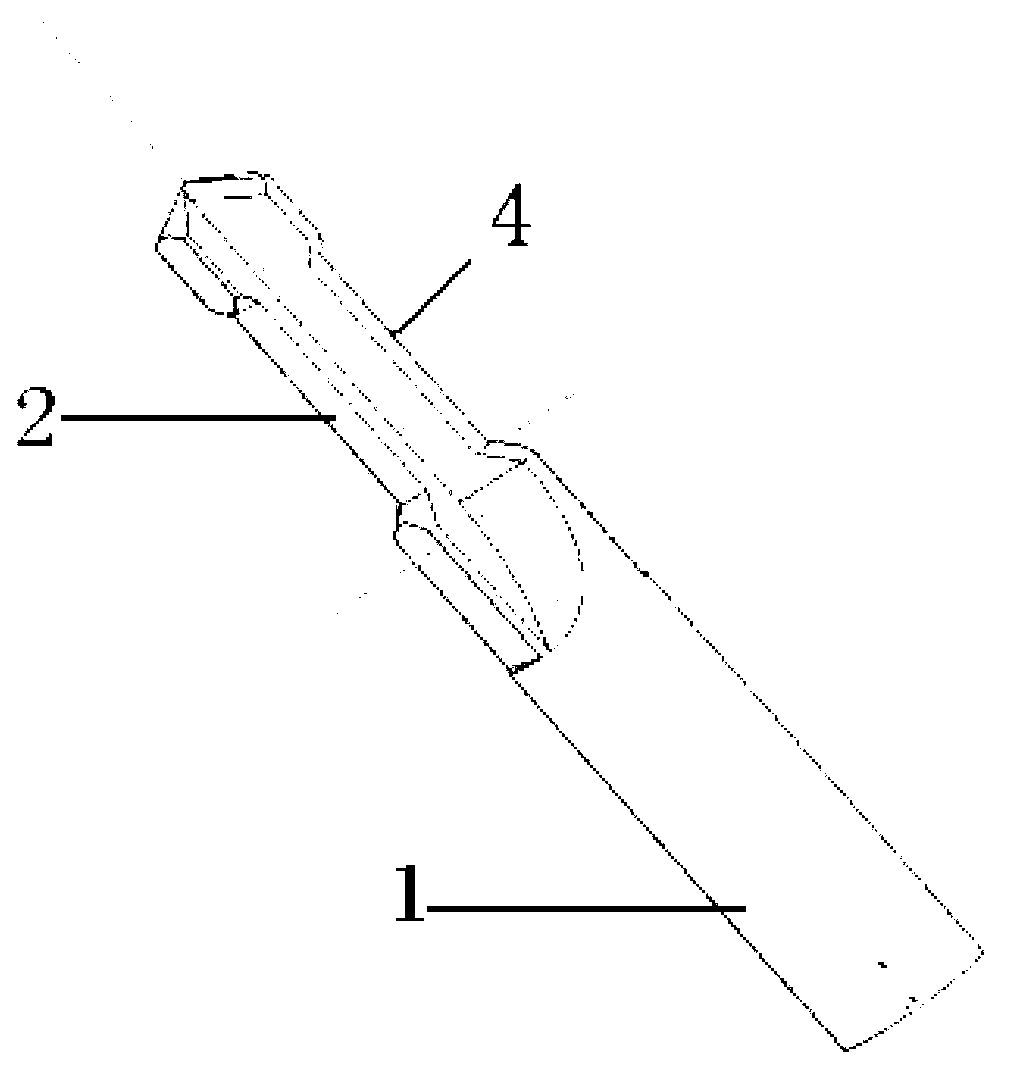

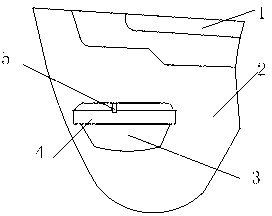

Drill bit applied to machining process

InactiveCN102847996AImprove processing efficiencyHigh degree of automationTransportation and packagingTrepanning drillsEngineeringAesthetic measure

The invention discloses a chamfering drill bit applied to a machining process. The chamfering drill bit comprises a drill stock, a drill body and a drill tip, wherein the drill tip is arranged at the front end of the drill body; the drill stock is arranged at the rear end of the drill body; the drill body is provided with double chamfer cutting edges; and chamfering directions of the double chamfer cutting edges are reverse. According to the technical scheme provided by the invention, a knife relieving groove is additionally arranged in a part of the drill body of a straight flue drill bit, and the chamfer cutting edges are additionally arranged at the two ends of the knife relieving groove, so that the knife replacing time is effectively saved, the effect of increasing the machining efficiency is obvious, a machining step of chamfering on a reverse face of the through hole is reduced, or the working load and the aesthetic measure brought by manual chamfering is removed, the degree of automatic machining is improved, and the three functions of drilling, chamfering on a front face of the hole and chamfering on a back face of the hole are realized.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

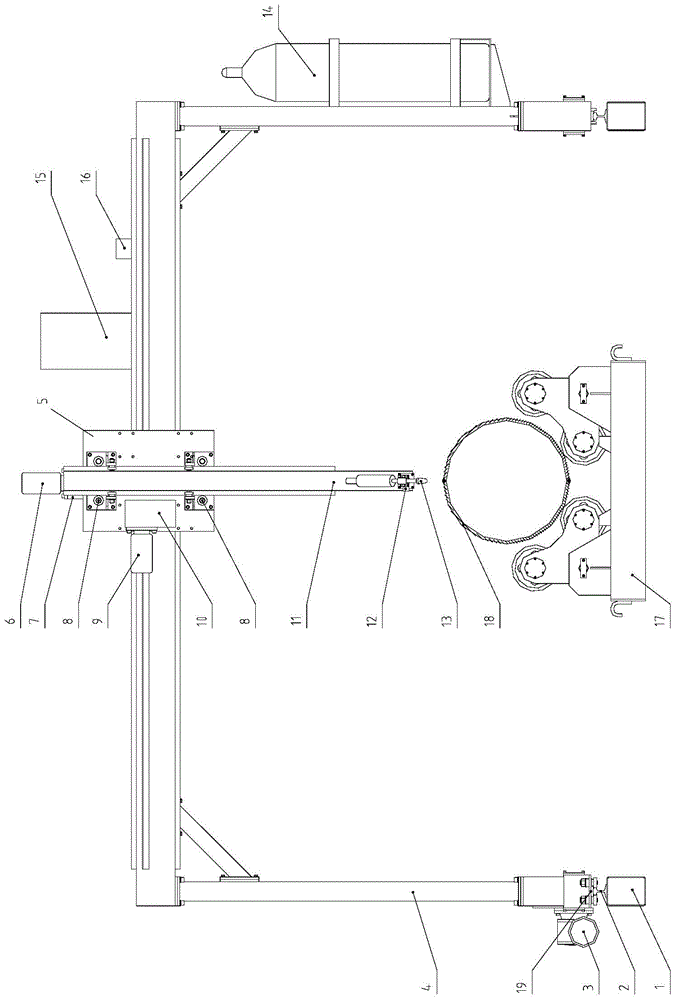

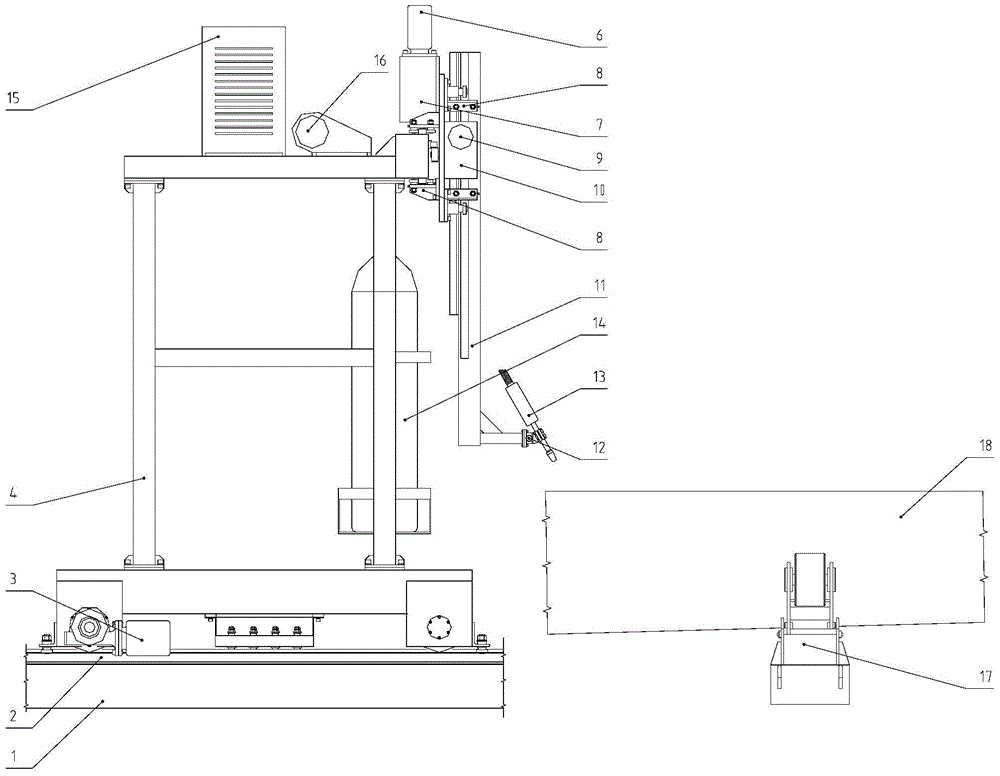

Gantry-type automatic welding and gouging integrated machine for welding steel pipe rods

ActiveCN104475918ALower skill requirementsReduce labor costsWelding/cutting auxillary devicesArc welding apparatusEngineeringReducer

The invention discloses a gantry-type automatic welding and gouging integrated machine for welding steel pipe rods, wherein the gantry frame is a door frame type rack formed by two vertical posts and one cross beam; the cross beam of the gantry frame is provided with a welding machine and a solder wire feeding machine. A crosswise cast iron convex guide rail on a crosswise dragging plate is in sliding match connection with a protruded grooved track on lateral side of the cross beam of the gantry frame; and the cross beam of the gantry frame is provided with a welding arm crosswise walking motor and a welding arm crosswise reducer, so as to provide power for the crosswise movement of the welding arm. Supporting guide rails on bilateral sides of the welding arm are in sliding match connection with vertical sliding chutes on the crosswise dragging plate; and the crosswise dragging plate is provided with a welding arm vertical walking motor and a welding arm vertical reducer, so as to provide power for the vertical movement of the welding arm. Compared with the prior art, the provided gantry-type automatic welding and gouging integrated machine for welding steel pipe rods is able to increase the comprehensive welding efficiency, quality and aesthetic measure of the product, and reduce the cost thereof.

Owner:ANHUI JIXI JIADE STEEL STRUCTURE

Large real-time wireless networking door control system powered by dry battery

ActiveCN101833802BImprove aestheticsGet rid of the defect of low service lifeData switching by path configurationIndividual entry/exit registersControl systemComputer module

The invention relates to a large real-time wireless networking door control system powered by a dry battery. The present door control system has complicated wiring and large power consumption. The large real-time wireless networking door control system powered by a dry battery comprises a door control management server, a PC client, an LAN (Local Area Network), a master controller, a wireless expansion module and a wireless door control lock, wherein the door control management server, the PC client and the master controller are in signal connection with the LAN, the master controller is in signal connection with the wireless expansion module, and the wireless expansion module is in signal connection with the wireless door control lock. The master controller and the wireless expansion module adopt RS485 communication connection and the wireless expansion module and the wireless door control lock which are in signal connection adopt a control protocol for communication connection. The wireless door control system is driven by the dry battery and no wiring is needed during the installation of the wireless door control management, thereby getting rid of defects that a wired power supply on the door lock reduces the aesthetic measure of the door and the service life is lowered for frequent bending of a power line in the prior art.

Owner:杭州英杰电子有限公司

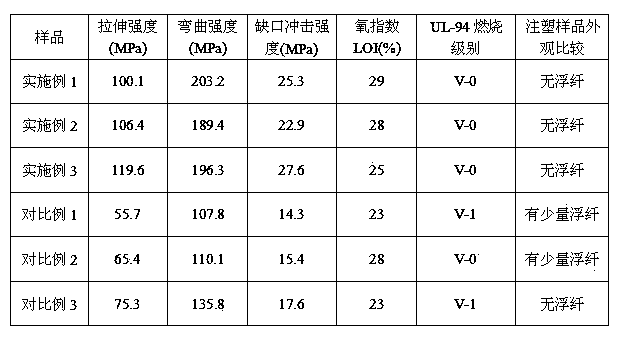

Long glass fiber flame-retardant reinforced nylon 6 composite material without fibers exposed to surface and preparation method of material

The invention relates to a long glass fiber flame-retardant reinforced nylon 6 composite material without fibers exposed to the surface and a preparation method of the composite material. The composite material is prepared from the following components in parts by weight: 30-80% of nylon 6, 10-60% of alkali-free long fibers, 2-10% of nano calcium carbonate, 1-3% of a main flame retardant, 0.5-1% of an auxiliary flame retardant, 2-5% of low viscosity nylon 6, 0.5-1% of a glass fiber modifier and 0.5-1% of other auxiliaries. The glass fibers provided by the invention have good compatibility with nylon 6 and are not exposed to the surface of the composite material and are smooth and attractive on the surface. By adopting double flame retardants, the flame retardance of the product is effectively improved and the flame retardance of the product can reach V-0 level, so that the composite material can be used on products such as home furnishing and offices and the like with relatively high surface smoothness or aesthetic measure and safety performance.

Owner:STARWAY INTERNATIONAL HOME LIVING CO LTD

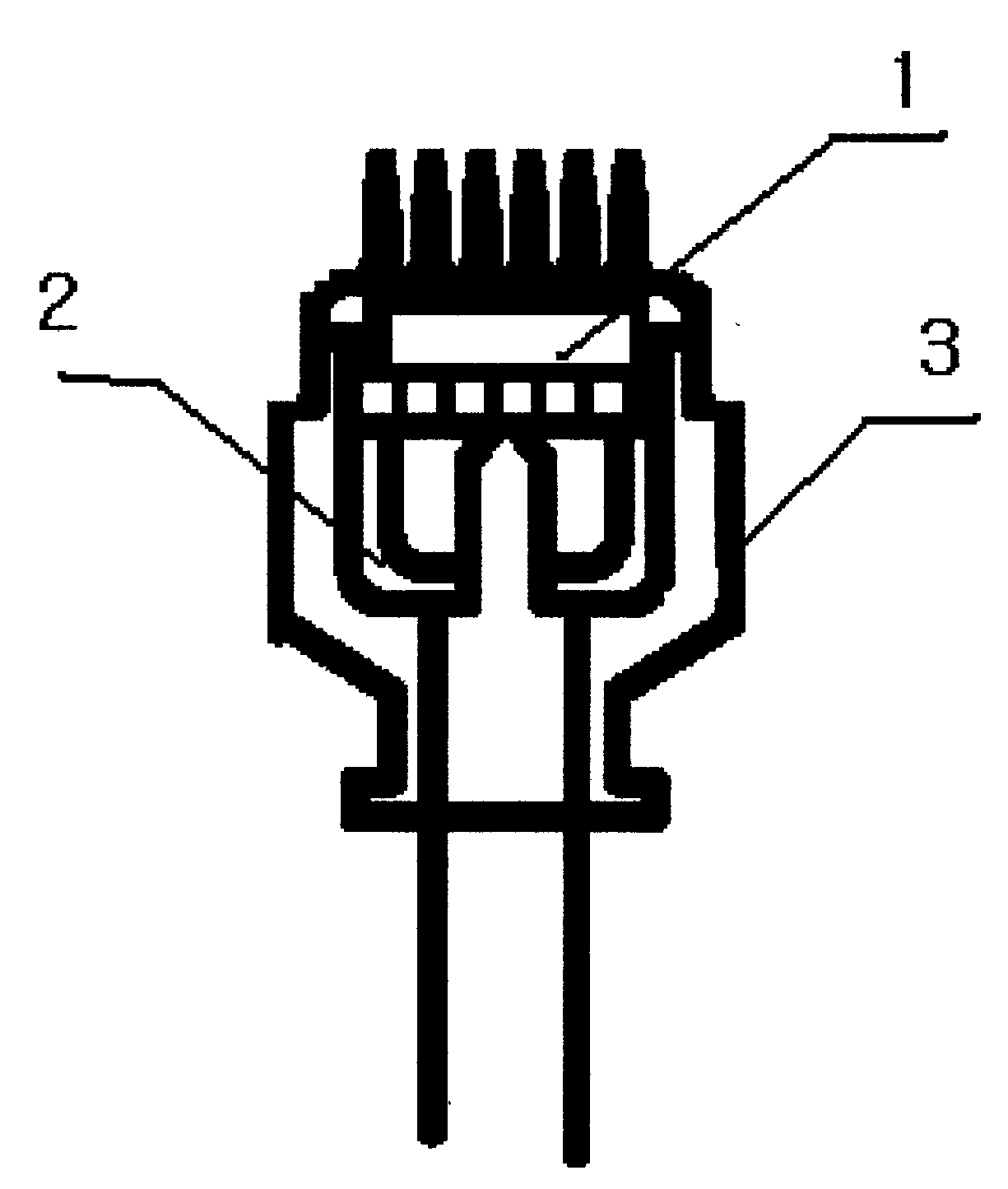

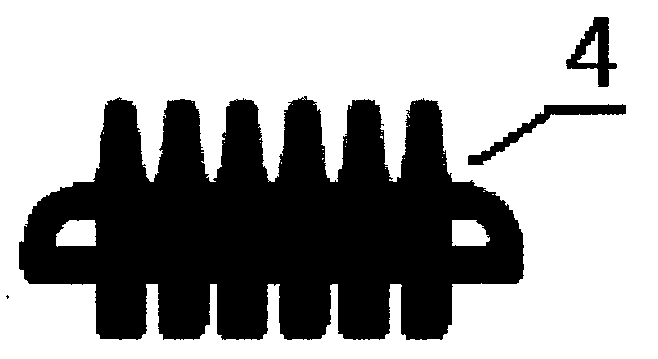

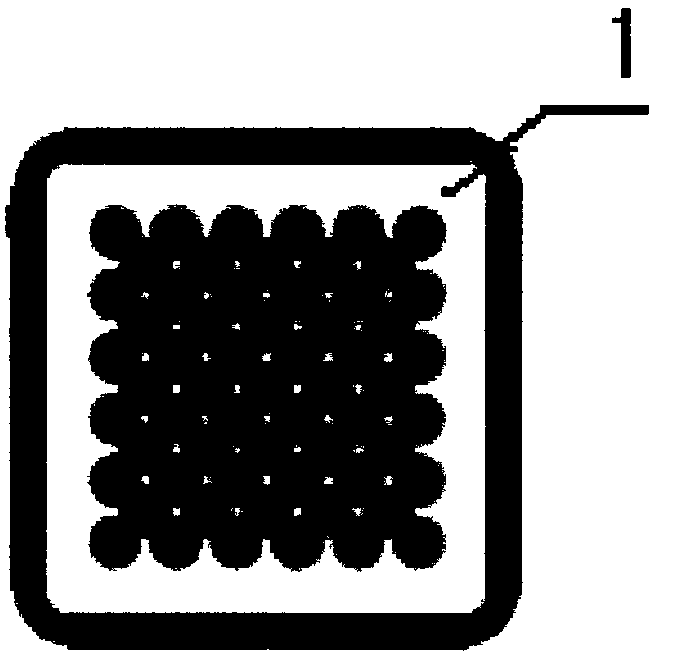

Manufacturing process flow of square microneedle massager

InactiveCN102166387AQuality improvementImprove practicalityMicroneedlesMedical devicesProtection KITIdler-wheel

The invention relates to a manufacturing process flow of a square microneedle massager. The invention comprises the structure of a square microneedle massager and a manufacturing process flow of the square microneedle massager. The structure of the square microneedle massager comprises a plastic needle piece set, a square cover and a protective cover, wherein the plastic needle piece set is internally provided with a plastic needle piece and a hole shell, the plastic needle piece comprises rows of needle holes with the same intervals and rows of air vents with the same intervals, the rows of the needles holes are alternately arranged with the rows of the air vents, the hole shell is provided with rows of square holes with the same intervals, the square holes and the air vents on the plastic needle piece have the same intervals and are communicated with each other, the hole shell is embedded into the square cover, the back of the square cover is provided with a plurality of air vents, and the square cover is embedded into the protective cover. The square microneedle massager is smooth and regular in appearance, free of gaps, more healthful and convenient to use, and thorough in sterilizing and cleaning, so that the use time of the product is increased, and the aesthetic measure of a microneedle idler wheel is further improved.

Owner:沈忠忠

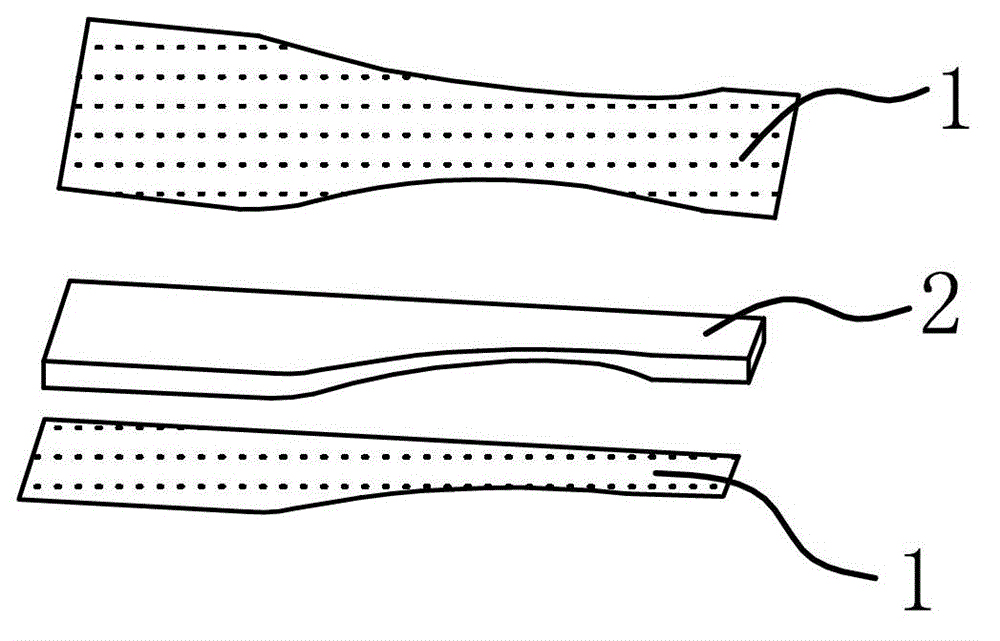

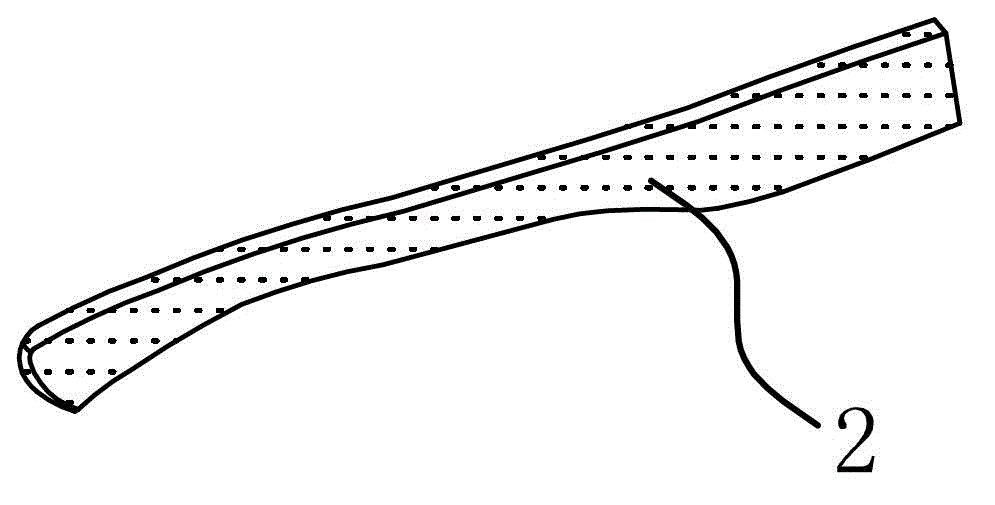

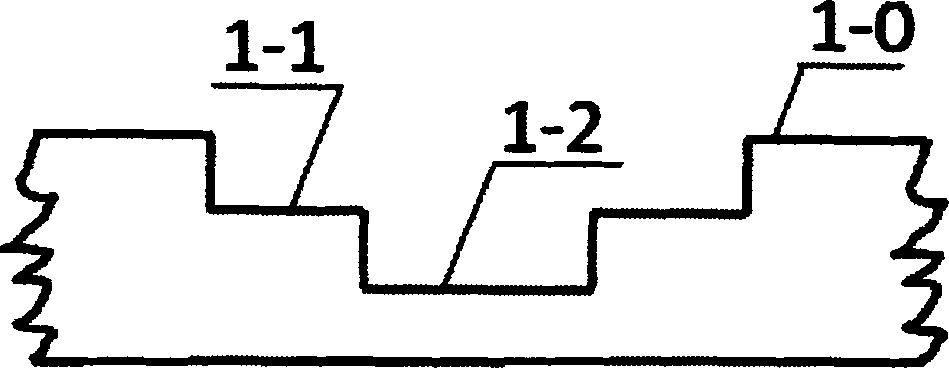

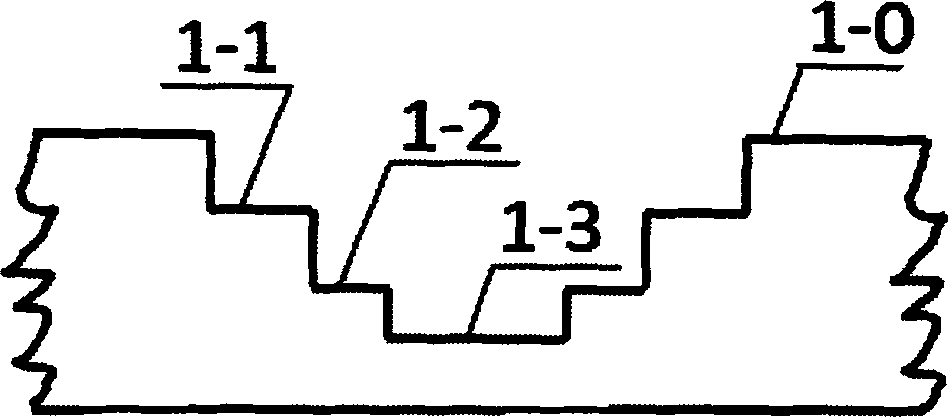

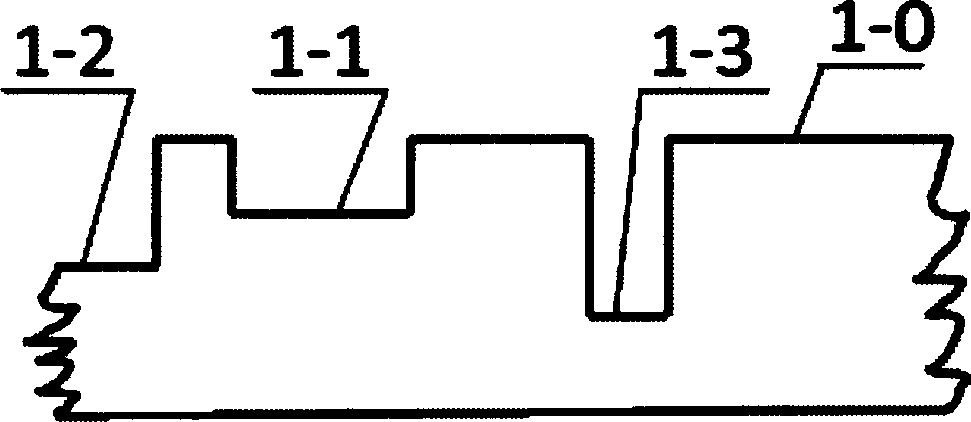

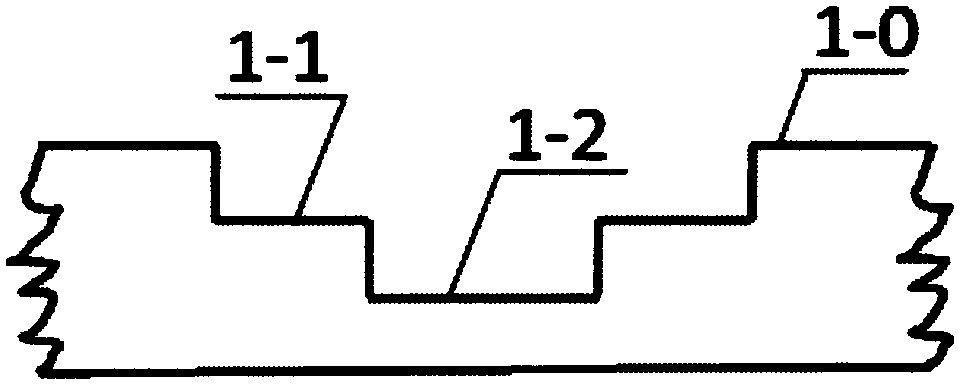

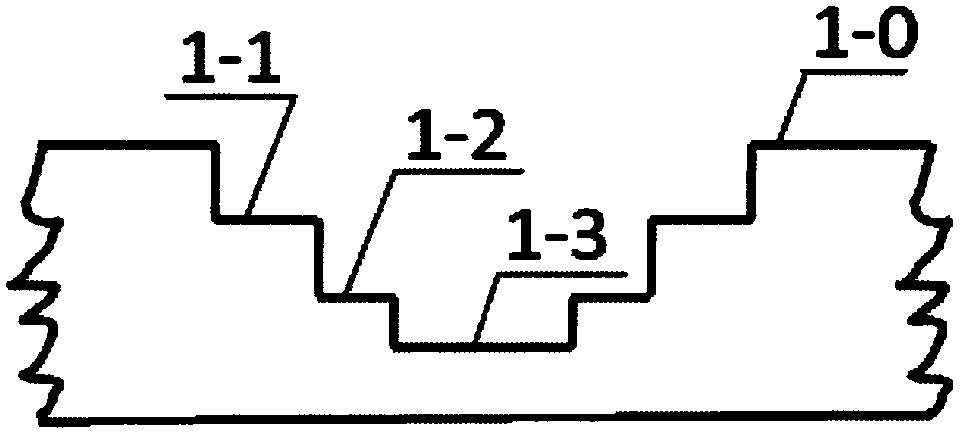

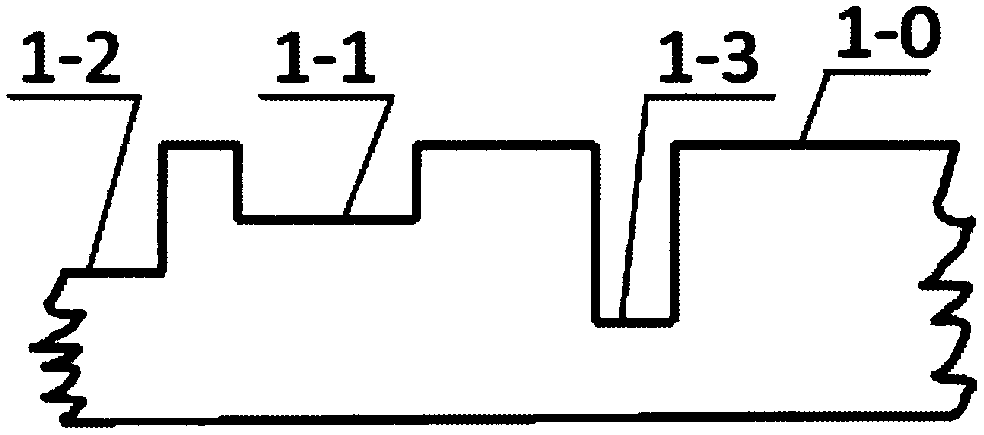

Preparation method of synchronously aligned and laminated plate

InactiveCN101797828AImprove fitImprove processing efficiencyLamination ancillary operationsLaminationAesthetic measureMaterials science

The invention discloses a preparation method of a synchronously aligned and laminated plate. The method comprises the following steps: a. determining a reference positioning point on a press, positioning a base plate and a facing layer, assembling, paving, and carrying out the high-accuracy alignment on a pattern printed on the surface of the facing layer and the template lines of an aligning and mold pressing steel plate arranged on the press; and b. mold pressing, setting the mold pressing process parameters to be as follows: the mold pressing unit pressure is 7.40-9.30MPa, the temperature of the aligning and mold pressing steel plate is 170-190 DEG C, and the mold pressing time is 35-40 seconds; and by mold pressing, laminating the facing layer on the surface of the base plate, and forming mold pressing lines which are aligned to the pattern printed on the outer surface of the facing layer at high accuracy. For the synchronously aligned and laminated plate prepared by the method, the pattern printed on the outer surface of the facing layer is aligned to the mold pressing lines at high accuracy. Besides, the technical scheme of the invention optimize the mold pressing procedures and parameters, and improves the laminating effect, the machining efficiency and the outer-surface aesthetic measure of the synchronously aligned and laminated plate.

Owner:广州易福诺木业有限公司

Surface treatment method of glasses leg

The invention provides a surface treatment method of a glasses leg, and belongs to the technical field of glasses manufacture. The method is used for solving the problems that the existing glasses leg is low in aesthetic measure and not fashionable enough after being subjected to surface treatment, and the like. The method comprises the following steps: A, surface coating; B, packing compact; and C, compaction. The method ensures that the treated glasses leg has an artistic structure and is exquisite and fashionable.

Owner:YUHUAN XIANGPENG GLASSES

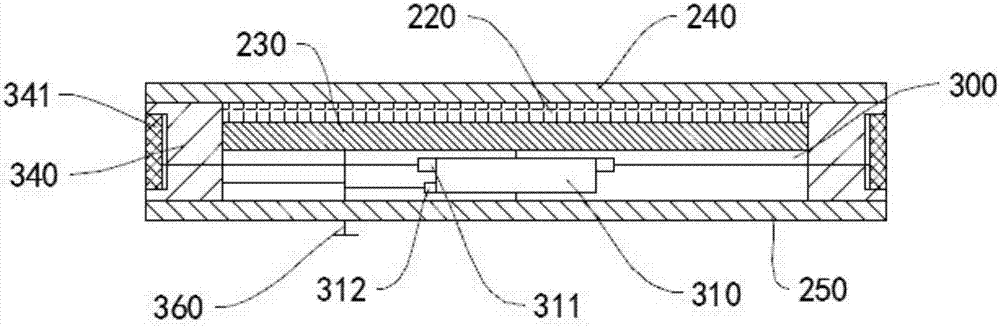

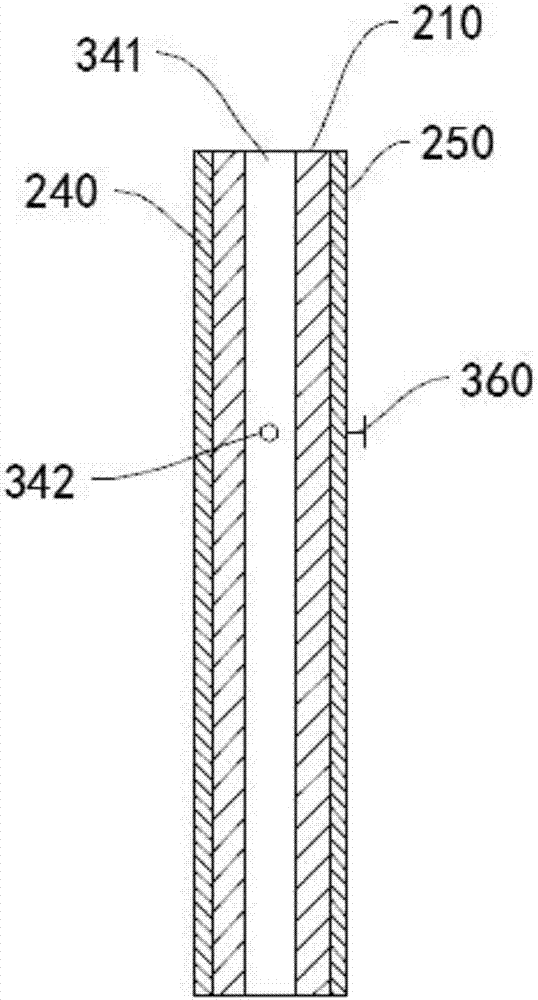

Noise reduction wooden door

InactiveCN107130896AImprove noise reductionLower requirementNoise insulation doors/windowsSpecial door/window arrangementsEngineeringNoise reduction

The invention discloses a noise-reducing wooden door, which is characterized in that it includes a door frame (100), and a door leaf (200) is arranged in the middle of the door frame (100); the door leaf (200) includes a rectangular frame body (210), and a A sound-absorbing layer (220), a core board (230) and a mechanism layer (300) are arranged in sequence, and a first panel (250) and a second panel (240) are arranged on both sides of the frame body (210). The mechanism layer (300) can block the door gap through the linkage structure to reduce noise when the door is closed. The invention has the characteristics of good noise reduction effect, high aesthetics and low cost. In addition, the present invention also has the feature of optional functions.

Owner:湖州南浔亨力木制品厂

Edge capping strip

The invention discloses an edge capping strip comprising an edge capping strip body, wherein the edge capping strip body is provided with an edge capping decorative surface on which an opening is arranged, an illuminating lamp is arranged in the opening, and the light emitting surface of the illuminating lamp is exposed out of the opening. According to the invention, the edge capping decorative surface is provided with the opening, the illuminating lamp is arranged in the opening, and the light emitting surface of the illuminating lamp is exposed out of the opening, so that the edge capping strip integrates functions of an electrical appliance, not only is the integral aesthetic measure of indoor decoration improved, but also the space is saved.

Owner:湖州民普厨卫科技有限公司

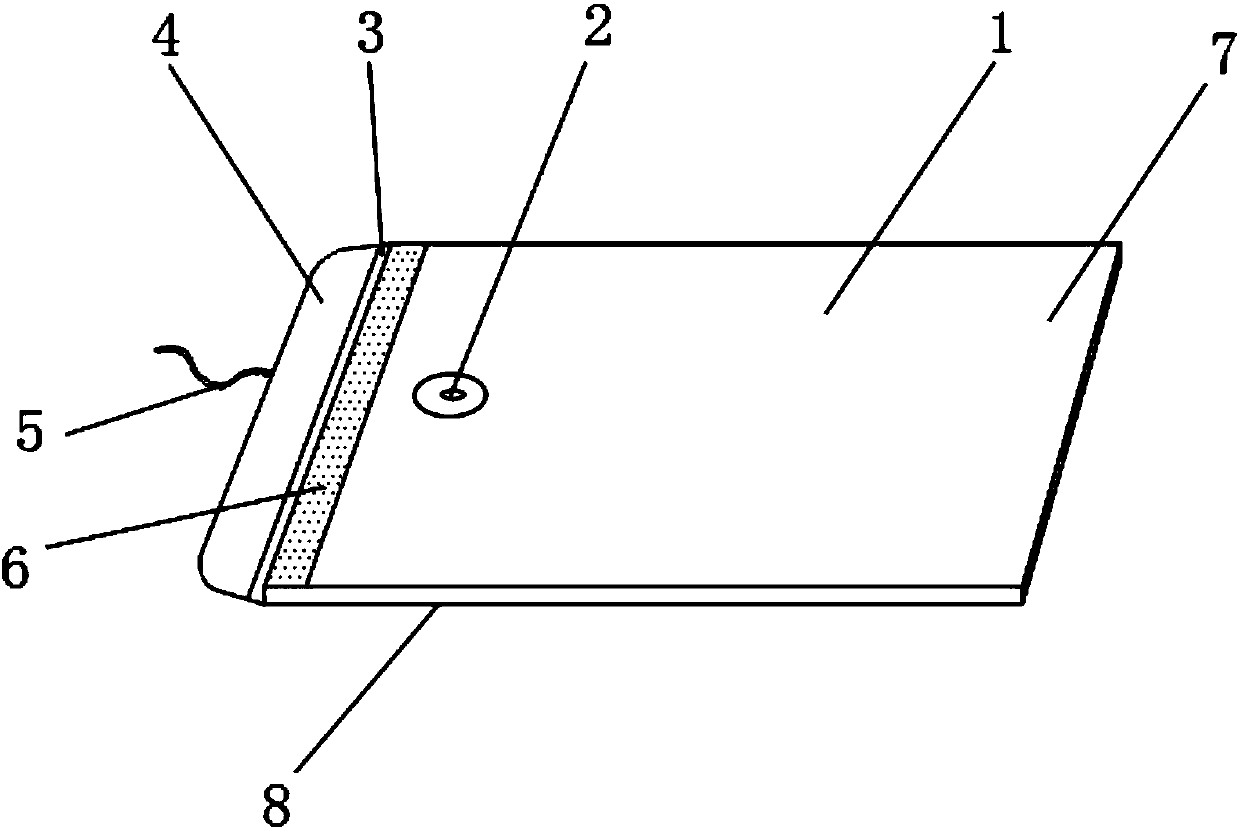

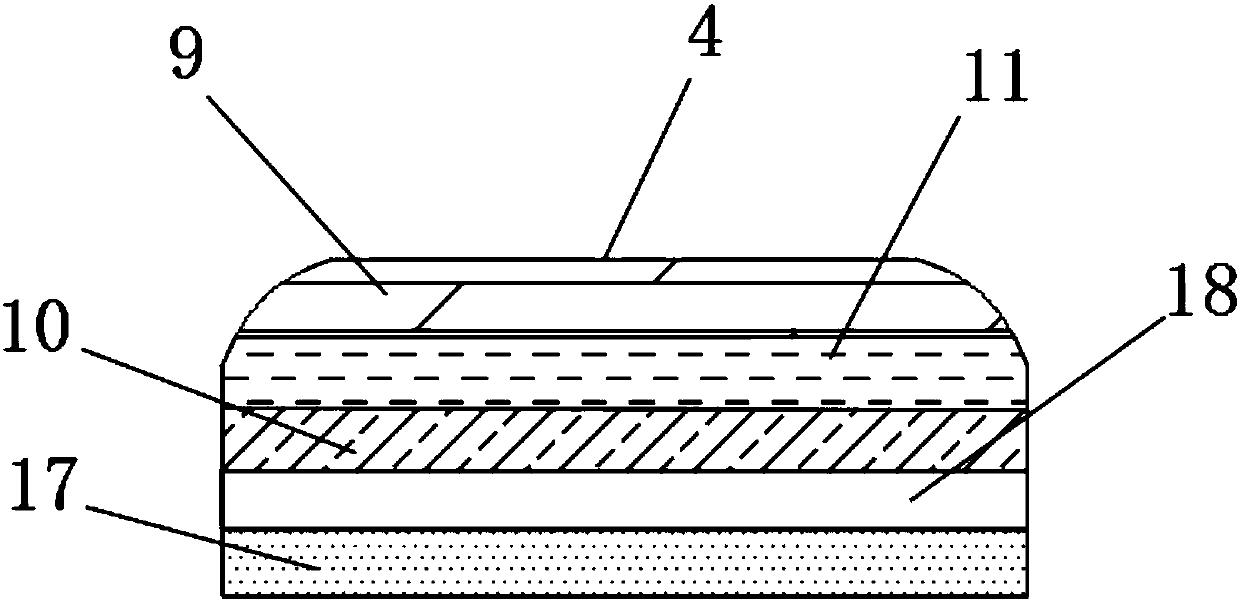

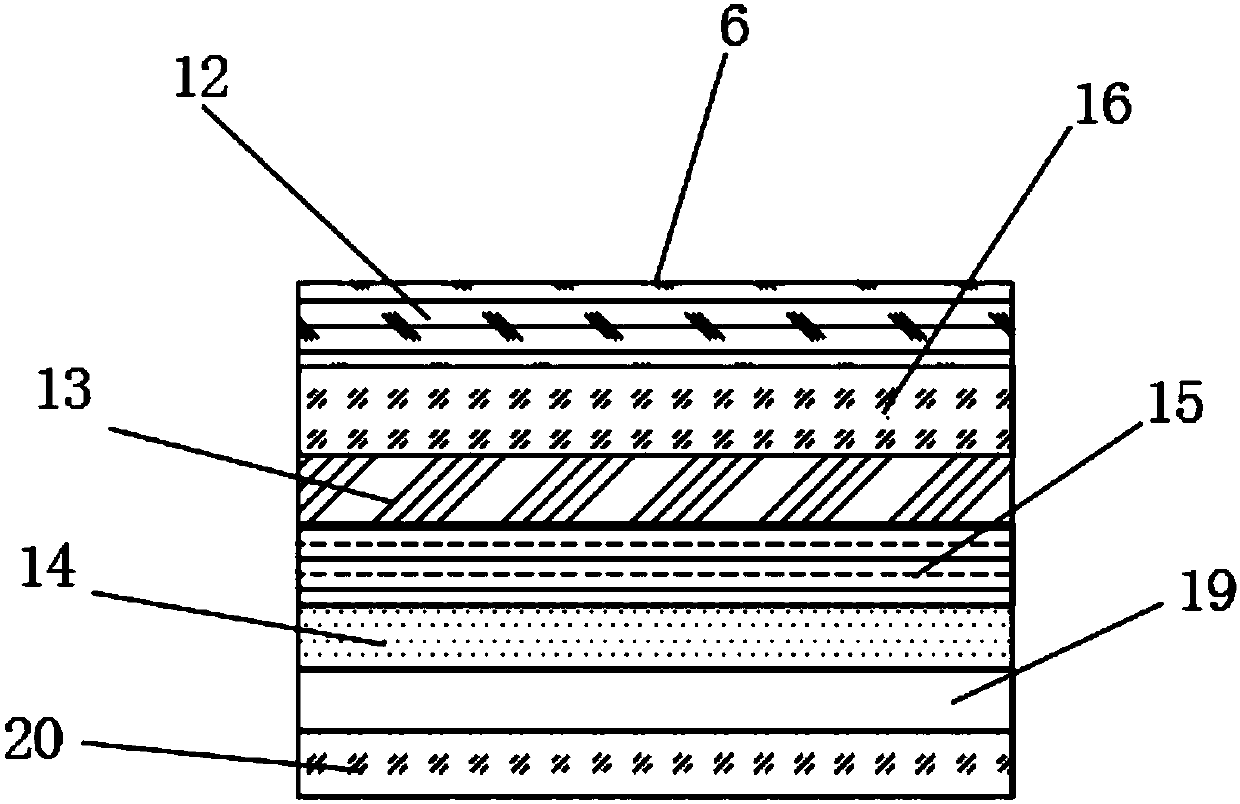

File pocket with adhesive sticker

The invention discloses a file pocket with an adhesive sticker. The file pocket comprises a file pocket body, a fastener, a fold, the adhesive sticker, a connecting line, a tag card sealing side, an upper seal bag, a lower seal bag, release paper, a surface paper layer, an adhesive layer, a frosted film-covered layer, a color printing layer, a plane base layer, a bonding layer, a containing cavity, a waterproof layer, a sheet, a thermal insulating layer and a film-covered bottom layer. The left side of the lower seal bag is provided with the adhesive sticker, the left side of the adhesive sticker is provided with the connecting line, and the right side of the adhesive sticker is provided with the fold; the right side of the tag card sealing side is provided with the fastener, and the middle of the interior of the tag card sealing side is provided with the bonding layer; and the thermal insulating layer is arranged over the film-covered bottom layer. According to the file pocket, the structure is simple, in the file management, sealing and storing processes, operation is easy and convenient, time and effort are saved, the workload of file management work is decreased, the file management efficiency is improved, using is convenient, moreover, flat and firm pasting is achieved, cleanness and tidiness as well as the aesthetic measure of a tag card are kept, and the applicability ishigh.

Owner:HUIZHOU HAOMING SCI & TECH

Method for processing 3D (three dimensional) flower type stuffed fabric

The invention discloses a method for processing a 3D (three dimensional) flower type stuffed fabric. The method for processing the 3D flower type stuffed fabric comprises the following steps: (1) producing villi on the surface of a shell fabric by virtue of a mechanical acting force; (2) extruding the villi on the surface of the shell fabric by adopting a flower roller with burn-out paste, wherein more than three layers of flower type patterns in different depths or different heights are formed in the surface of the flower roller; (3) heating the shell fabric the villi of which are coated with the burn-out paste by virtue of a drying oven, dissolving the villi contacted with the burn-out paste by the burn-out paste, then regulating the pH value of the shell fabric, and cleaning by adopting clear water; (4) carrying out aftertreatment on the cleaned shell fabric, thus the 3D flower type stuffed fabric is obtained. The method for processing the 3D flower type stuffed fabric has the advantages that more than three layers of burn-out patterns are formed in the surface of the processed stuffed fabric; 3D flower type stereoscopic impression is extremely strong, the defects that a frequently-used burn-out velvet flower type on the market is single in structural design, layout is not scientific enough, aesthetic measure is poor and handfeel is poor can be overcome, and appearance is attractive while the shell fabric is in a special style, so that the 3D flower type stuffed fabric can be applied to interior decorations of a sofa, a curtain and a bedspread and the like.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

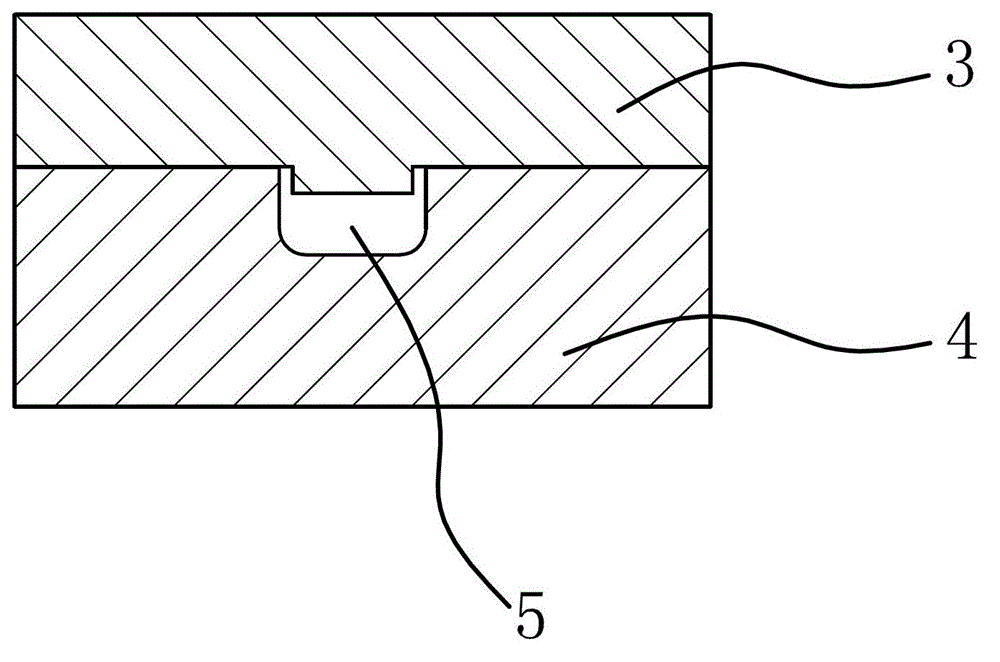

Method for ensuring wide bright decorative strip to be free of distortion

InactiveCN107030962ASmall contraction forceGuaranteed beautyVehicle componentsDomestic articlesEngineeringAesthetic measure

The invention relates to a method for ensuring a wide bright decorative strip to be free of distortion. The method is characterized in that the wide bright decorative strip is ensured to be free of distortion by adopting one or more of methods of reducing PVC material dosage, reducing a connecting area between PVC and the bright decorative strip or transferring PVC material shrinking force between the bright decorative strip and glass during edge covering of glass. Compared with the prior art, the method has the advantages of reducing PVC edge-covering shrinking force in aspects of a force acting object, a force transmission medium, a force generating object and the like, so that the shrinking force is within a bearing range of the bright decorative strip, and the aesthetic measure of the bright decorative strip is ensured.

Owner:SHANGHAI FUYAO BUS GLASS

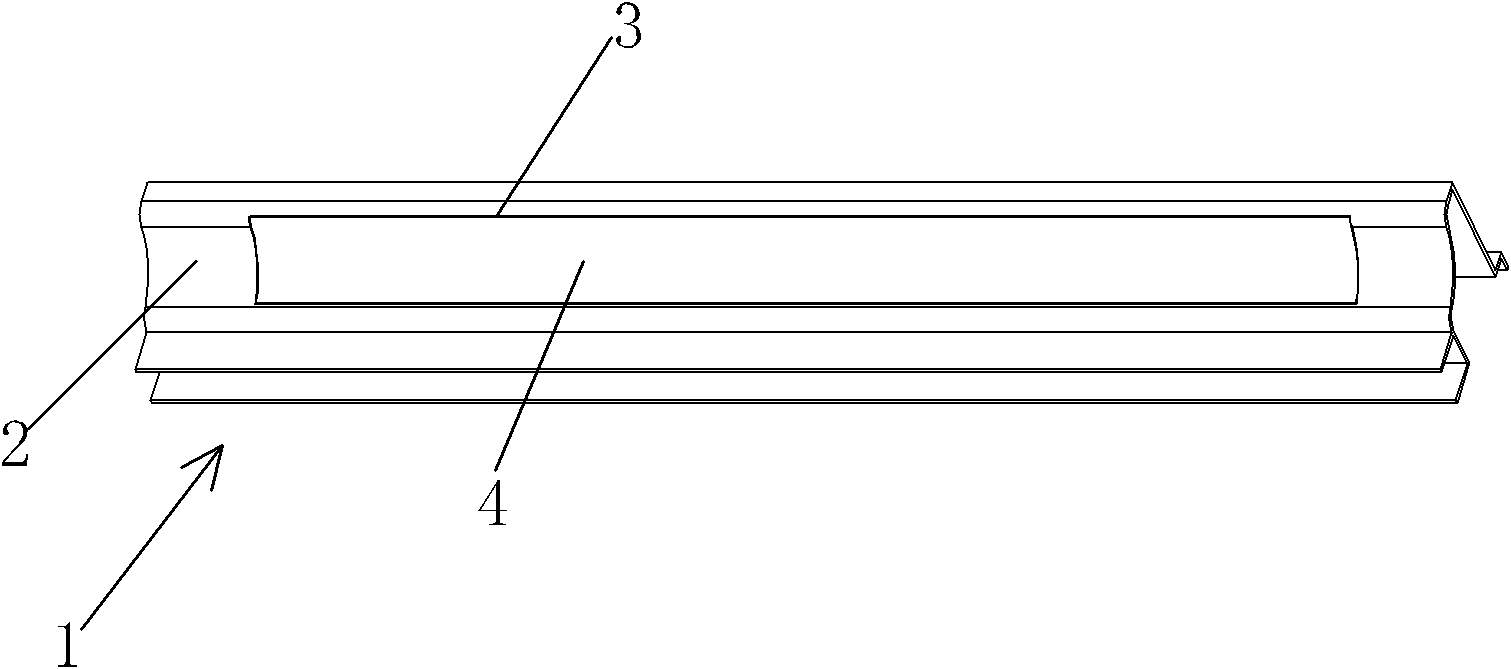

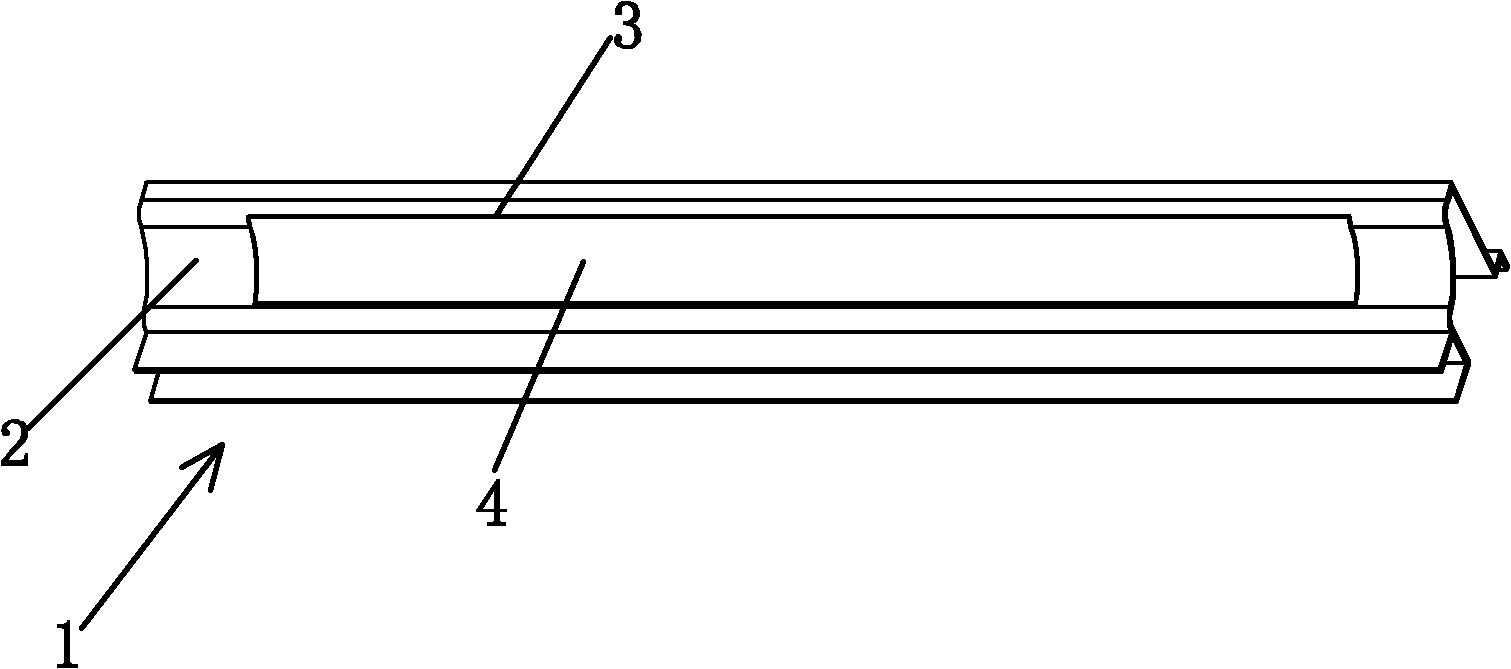

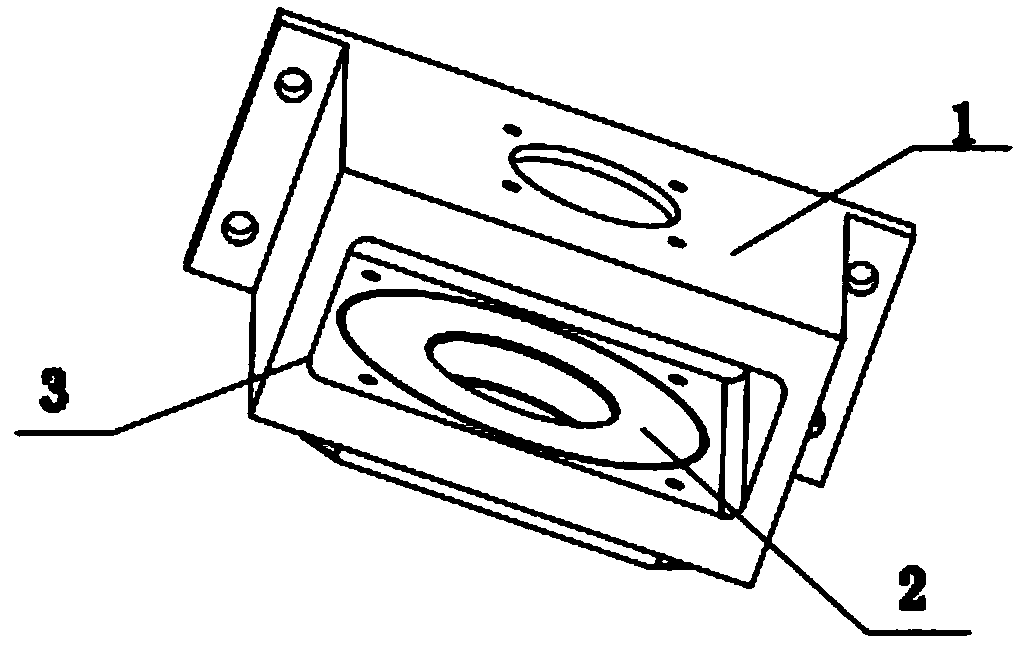

Equipment and technology used for UV coating and combination release manufacturing of super high finish paper

The invention discloses equipment and technology used for UV coating and combination release manufacturing of super high finish paper. The equipment comprises an unreeling part 1, an unreeling part 2,a printing part, a combination part 1, a combination part 2, a reeling part 1, and a reeling part 2; a UV drying part 1 is arranged on one side of the downstream of the combination part 1; a UV drying part 2 is arranged on one side of the downstream of the combination part 2; a guiding shaft 1 is arranged between the unreeling part 1 and the combination part 1; a guiding shaft 2 is arranged between the unreeling part 2 and the printing part; a guiding shaft 3 is arranged between the UV drying part 2 and the reeling part 1; a guiding shaft 4 is arranged between the UV drying part 2 and the reeling part 2. Compared with the prior art, the equipment and the technology possesses following advantages: the equipment length is not longer than 5m; no hot wind drying is adopted; no drying channelis adopted; glossiness treatment can be completed using one equipment; product flatness and brightness are improved greatly; space and energy are saved greatly; and product production efficiency and aesthetic measure are improved.

Owner:东莞市锐泽创艺新材料有限公司

Cover type storage car door

InactiveCN103158508APrevent spillageImprove aestheticsPassenger spaceDoorsEngineeringAesthetic measure

The invention relates to a cover type storage car door which comprises a door body. The cover type storage car door is characterized in that an inner trim panel is arranged on the inner side of the door body, a containing space is arranged on the inner trim panel, the containing space is an article placing space, a baffle is arranged on the periphery of the article placing space, and a shielding cover is arranged on the top of the article placing space. Thus, the shielding cover is matched with the article placing space, the needs for placing various articles can be met, and meanwhile, the placed articles can be prevented from overflowing at a bumping stage in the driving process of a car. Furthermore, a decorative material layer is arranged, and the aesthetic measure of interior decoration can be improved.

Owner:SUZHOU WANLONG AUTO PARTS

Color enhancement method of remote sensing image based on multi-scale image segmentation and color transfer

InactiveCN103136733BImprove legibilityReduce color transfer errorsImage enhancementWavelet denoisingLightness

Owner:NO 61 INST OF GENERAL STAFF +1

A floor tile caulking device with automatic gap cleaning function

The invention belongs to the technical field of interior decoration, and particularly discloses a floor tile joint filling device with an automatic gap cleaning function. The floor tile joint fillingdevice comprises a box body, a walking module, a scrubbing module, a wipe-drying module and a joint filling module, and the walking module is used for driving horizontal movement of the box body; thescrubbing module is located inside the box body, and the scrubbing module is used for cleaning stains in gaps of floor tiles and uniformizing the gap width, thereby improving effect and aesthetic measure of joint filling; the wipe-drying module is located at the right side of the scrubbing module, and the wipe-drying module is used for cleaning the stains around the gaps of the floor tiles treatedby the scrubbing module, ensuring a dry environment of the gaps and preparing for the joint filling; and the joint filling module is located at the right side of the wipe-drying module, and the jointfilling module is used for filling a joint filling agent to the gaps cleaned and dried by the wipe-drying module to complete the joint filling work. According to the floor tile joint filling device with the automatic gap cleaning function, the effective cleaning and drying of the gaps of the floor tiles can be realized firstly, and then the treated gaps are subjected to the joint filling work, sothat the work efficiency is high, and the gaps are attractive.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Landscape lamp powered by solar energy

PendingCN110425479AEasy to replaceEasy maintenanceLighting support devicesWith built-in powerEngineeringAesthetic measure

The present invention discloses a landscape lamp powered by solar energy. The landscape lamp powered by solar energy comprises a base; the top of the base is fixedly connected with a column; the top of the base is provided with a ring hole; both sides of the column are provided with a slide rail separately; the bottom of the inner cavity of the base is connected with a threaded rod through a bearing; and an outer surface of the threaded rod arranged at one end of the inner cavity of the base is fixedly connected with a turntable. According to the landscape lamp powered by solar energy providedby the present invention, by setting the slide rails, the threaded rod, the turntable, the rotating rod, the ring hole and the thread sleeve, the effects of driving the lifting and lowering of the lighting mechanism, and facilitating the replacement and maintenance of the components in the lighting mechanism are achieved; by setting an electric telescopic rod, the effect of adjusting the illumination angle is achieved; and by setting the fixing plate and the bolt, the effect of facilitating the replacement of the illumination lamp is achieved, and the problems that the existing solar landscape lamp is time-consuming and laborious in repairing and replacing the lamp body, and the aesthetic measure is reduced due to that the illumination angle of the lamp body is fixed are solved.

Owner:泰州市华强照明器材有限公司

An automated method for intelligent color matching of graphics

ActiveCN105303587BReduce labor intensityAvoid Color Extraction BiasImage analysisCharacter and pattern recognitionPattern recognitionHarmonization

The invention discloses an automated and intelligent figure color matching method and belongs to the figure design technical field. The method includes the following steps that: representative colors are extracted from a known source figure, color harmonization is performed on the color matching scheme of the source figure, so that the color matching scheme of a designed figure requiring color matching is obtained; and the mapping relationship between the color matching scheme of the source figure and the color matching scheme of the designed figure is established, and representative colors of the designed figure are selected, so that a series of color matching scheme mappings of the designed figure can be formed. With the automated figure intelligent color matching method of the invention adopted, the labor intensity of designers can be reduced, and color matching efficiency can be improved. According to the automated figure intelligent color matching method, aesthetic measures are adopted to measure the quality of the color matching schemes, and therefore, the automated and intelligent figure color matching method is intelligent.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

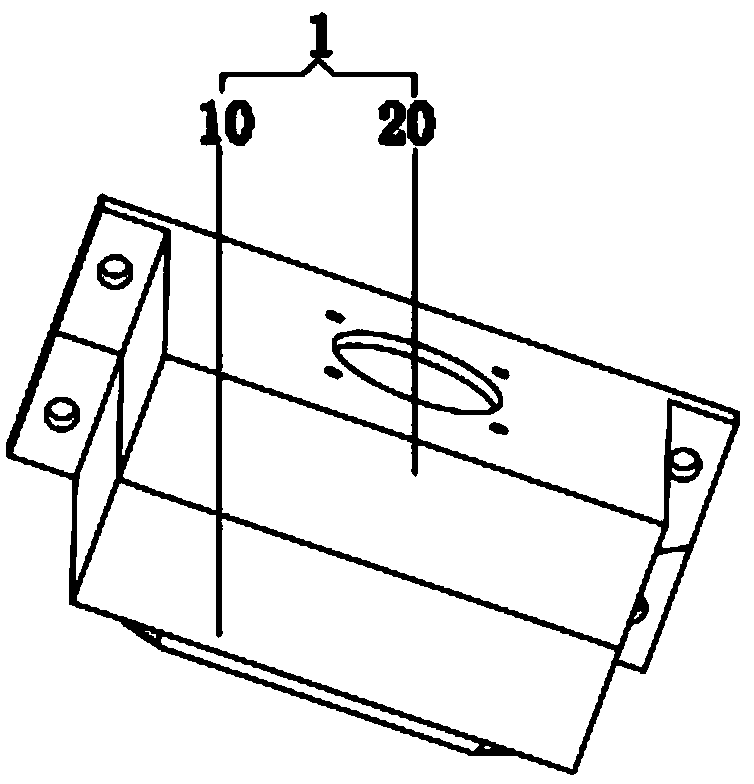

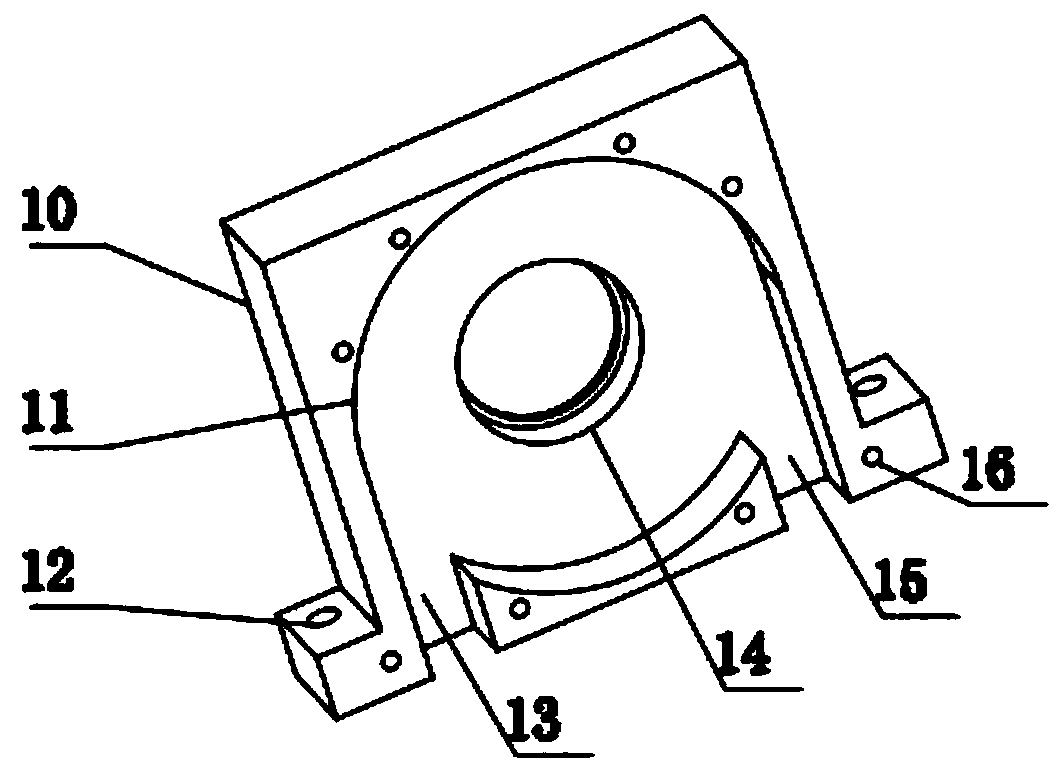

Half type aluminum belt wheel seat

PendingCN108716534AImprove aestheticsReduce the amount of processingGearing detailsBearing unit rigid supportEngineeringAesthetic measure

The invention belongs to the technical field of machining and in particular relates to a Half type aluminum belt wheel seat. The Half type aluminum belt wheel seat comprises a seat body composed of anupper half seat body and a lower half seat body mounted in the bottom of the upper half seat body, wherein half seat cavities are formed in the middle parts of assembling junction surfaces of the upper and lower half seat bodies; a belt passageway A and a belt passageway B are arranged on the lower part of each half seat cavity along the tangential direction of the half seat cavity; Half body fixed via holes are formed around each half seat body, small bumps are integrally formed in two sides of the lower parts of the upper and lower half seat bodies; a bearing mounting position provided withsteps is arranged in the middle part of each half seat cavity; and reducing motor flange fixing screw holes are uniformly formed in the top of the upper half seat. By adopting a common thickness material, the processing amount is reduced, the processing technology is changed, the processing difficulty is reduced, the processing precision is guaranteed, the aesthetic measure of the appearance is improved, and the material cost and the processing cost are reduced greatly.

Owner:郑州圻心智能设备有限公司

Infrared laser traffic information acquisition instrument

InactiveCN100589144CLess aesthetically pleasingWill not missDetection of traffic movementHigh densityLight beam

The invention relates to an infrared laser traffic information collector which comprises a support positioned beside a road, a first infrared laser sensor, a second infrared laser sensor, a controller, a first reflective tape and a second reflective tape; wherein the first infrared laser sensor and the second infrared laser sensor are fixed on a cross bar positioned on the support, and are connected with the controller through cables; The infrared laser traffic information collector has the advantages that the installation is simple, and no portal frame is required to be arranged on the road;the overall cost is low; the influence on the aesthetic measure of the environment is greatly reduced; the collector can be suitable for being distributed in a high density detection station; and thescanning is performed through the light beam of the infrared laser sensors along the width of the traffic lane, so that miss of vehicle detection can not happen.

Owner:ZHONGJIAO YUANZHOU TRAFFIC TECH GROUP +1

Jewelry Sandblasting Process

ActiveCN106363534BImprove processing efficiencyImprove aestheticsPolishing machinesGrinding machinesGranularitySand blasting

Owner:LAOFENGXIANG DONGGUAN JEWELRY CO LTD

Processing method of 3D pattern plush fabric

The invention discloses a method for processing a 3D (three dimensional) flower type stuffed fabric. The method for processing the 3D flower type stuffed fabric comprises the following steps: (1) producing villi on the surface of a shell fabric by virtue of a mechanical acting force; (2) extruding the villi on the surface of the shell fabric by adopting a flower roller with burn-out paste, wherein more than three layers of flower type patterns in different depths or different heights are formed in the surface of the flower roller; (3) heating the shell fabric the villi of which are coated with the burn-out paste by virtue of a drying oven, dissolving the villi contacted with the burn-out paste by the burn-out paste, then regulating the pH value of the shell fabric, and cleaning by adopting clear water; (4) carrying out aftertreatment on the cleaned shell fabric, thus the 3D flower type stuffed fabric is obtained. The method for processing the 3D flower type stuffed fabric has the advantages that more than three layers of burn-out patterns are formed in the surface of the processed stuffed fabric; 3D flower type stereoscopic impression is extremely strong, the defects that a frequently-used burn-out velvet flower type on the market is single in structural design, layout is not scientific enough, aesthetic measure is poor and handfeel is poor can be overcome, and appearance is attractive while the shell fabric is in a special style, so that the 3D flower type stuffed fabric can be applied to interior decorations of a sofa, a curtain and a bedspread and the like.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com