Drill bit applied to machining process

A kind of mechanical processing and drilling technology, which is applied in the direction of metal processing equipment, drill repairing, drilling tool accessories, etc., can solve the problems of increasing chamfering process, increasing processing time, increasing workload, etc., so as to reduce processing steps and save tool change time , the effect of increasing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

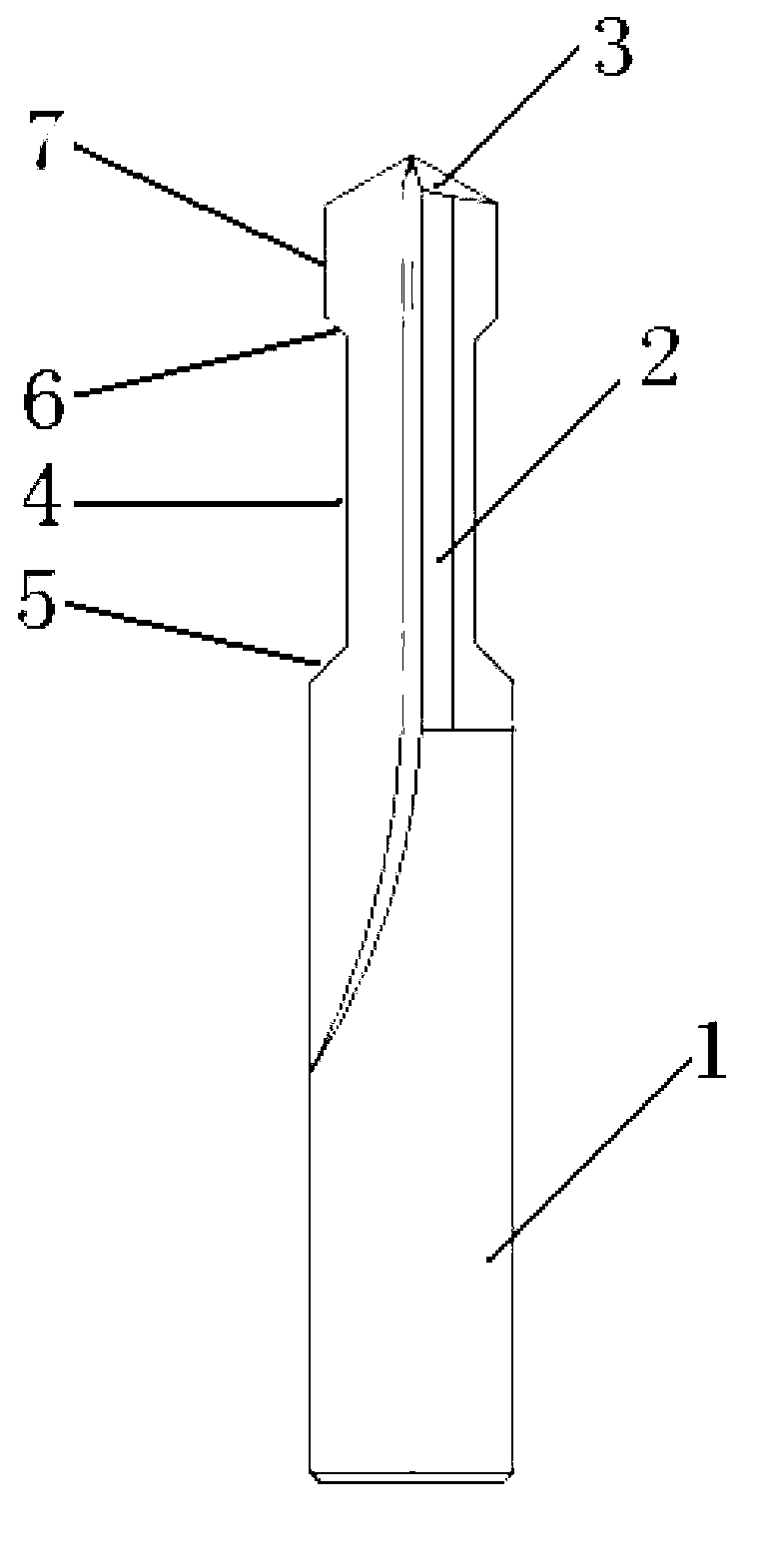

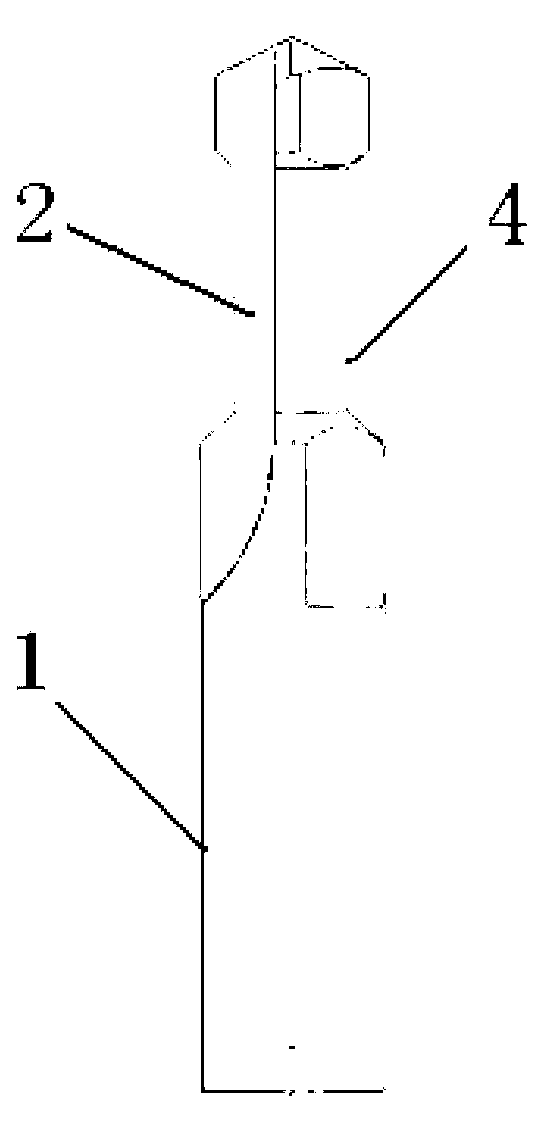

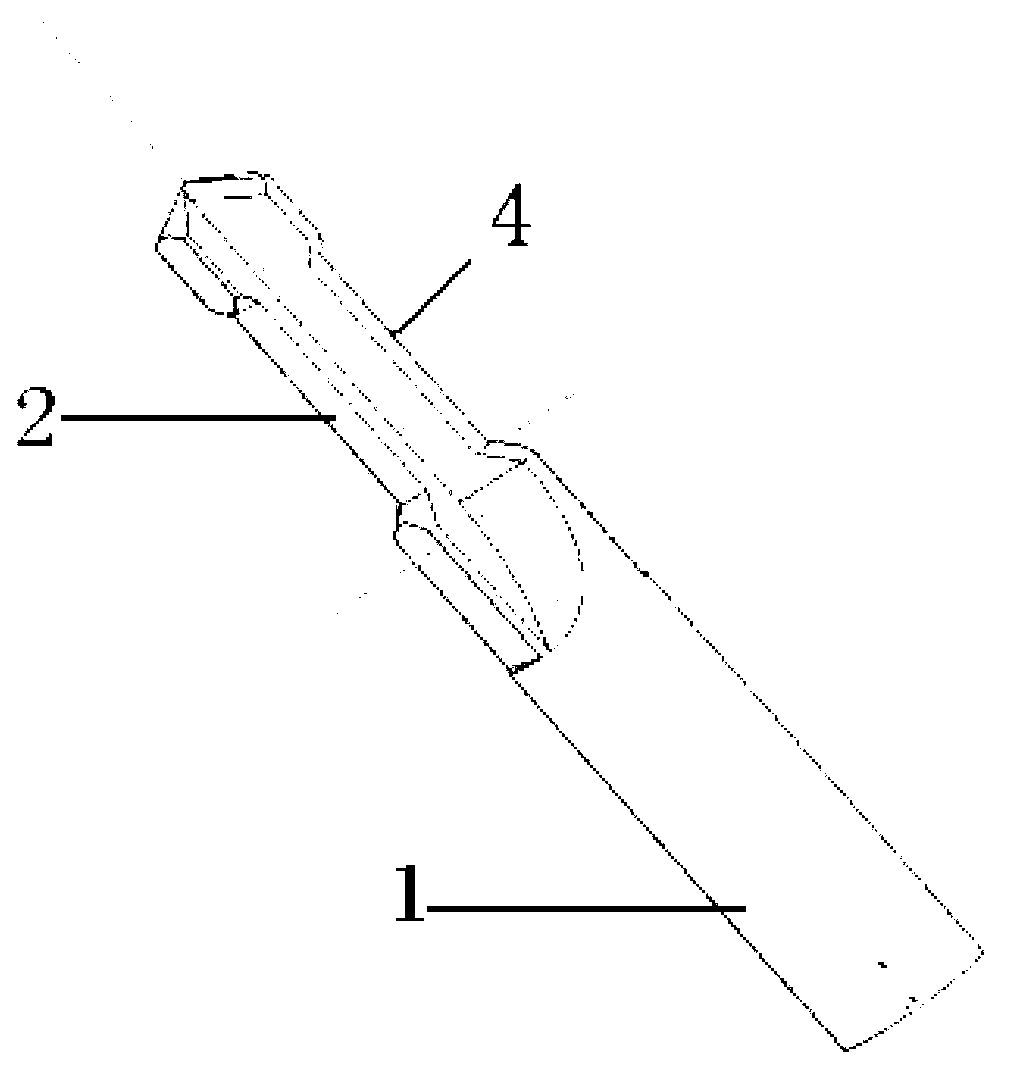

[0024] Such as Figure 1~3 As shown, the technical solution provided by the present invention is a chamfering drill applied in mechanical processing technology, including a drill shank 1, a drill body 2 and a drill tip 3, and the drill tip 3 is arranged on the drill body 2 The front end of the drill shank 1 is arranged at the rear end of the drill body 2, and the drill body 2 is provided with double chamfered cutting edges, and the chamfering directions of the double chamfered cutting edges are opposite. The drill body 2 is provided with a relief groove 4 , and the double-chamfered cutting edges are arranged at both ends of the relief groove 4 . The double chamfer cutting edge includes a forward chamfer cutting edge 5 and a reverse chamfer cutting edge 6, and the reverse chamfer cutting edge 6 is arranged at the front end of the sipe 4, that is, close to the drill tip 3 at one end. The forward chamfering cutting edge 5 is arranged at the rear end of the sipe 4 , that is, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Drilling depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com