Surface treatment method of glasses leg

A technology for surface treatment and glasses legs, applied in the field of surface treatment of glasses legs, can solve the problems of low aesthetics, not fashionable enough, etc., and achieve the effect of wide selection, beautiful structure and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

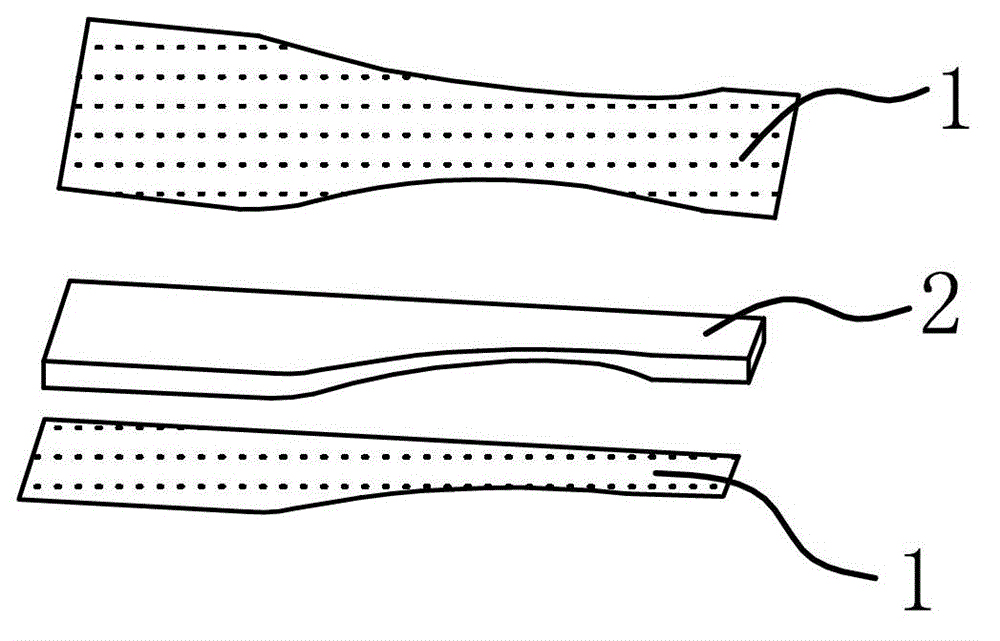

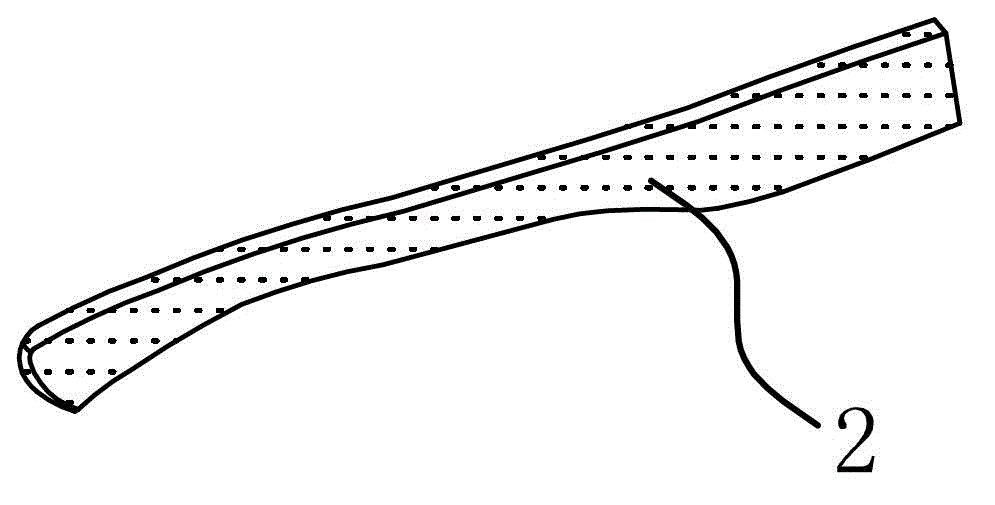

[0030] Such as figure 1 , figure 2 , image 3 Shown, the surface treatment method of this spectacle pin comprises the following steps:

[0031] A. Surface coating: Use carbon fiber cloth to heat press the temple body 2, apply epoxy resin glue evenly on one side of the carbon fiber pattern cloth 1, cut out a rectangular carbon fiber pattern cloth 1, and then pack 1 bag of carbon fiber pattern cloth Overlay on the four sides of the foot body 2;

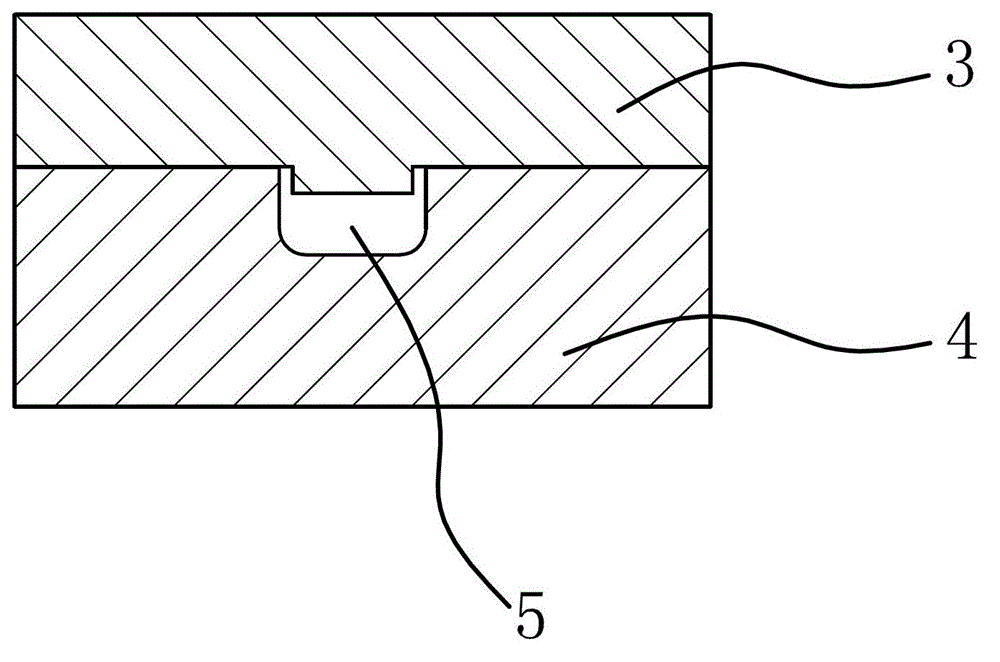

[0032] B. Mold loading: the temperature of the mold is set to 150°C, which includes an upper mold body 3 and a lower mold body 4. In this embodiment, the upper mold body 3 and the lower mold body 4 are made of silicon rubber materials. Among them, the upper mold body 3 can be made of metal material, and the lower mold body 4 is made of silicon rubber material, and different molds can be replaced according to actual needs. There is an elongated molding cavity 5 at the position corresponding to the upper mold body 3 and the lower mol...

Embodiment 2

[0036] The scheme of this embodiment is basically the same as that of Embodiment 1, the difference is that the foot body 2 in step A is made of metal material, and only covers the inner and outer sides of the foot body 2 with a larger area. The mold is set at a temperature of 300° C., the foot body 2 is hot-pressed with a pressure of 8 tons in step C, and the thickness of the paint sprayed is 20 microns.

Embodiment 3

[0038] The scheme of this embodiment is basically the same as that of Embodiment 1, the difference is that the foot body 2 in step A is made of plastic material, and covers the outer side and the upper and lower sides of the foot body 2, and the foot body 2 in step B The mold is set at a temperature of 100° C., and in step C, the foot body 2 is hot-pressed with a pressure of 5 tons, and the thickness of the paint sprayed is 30 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com