Long glass fiber flame-retardant reinforced nylon 6 composite material without fibers exposed to surface and preparation method of material

A composite material and long glass fiber technology, applied in the field of organic polymer nanocomposite materials, can solve the problems of unsmooth surface, poor flame retardancy, unreachable flame retardancy, etc., achieve good social value and experience value, reduce Flame retardant cost, effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

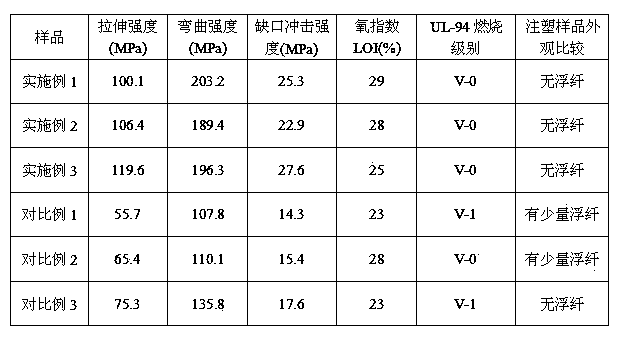

Examples

Embodiment 1

[0023] Long glass fiber flame retardant reinforced nylon 6 composite material with no fiber exposed on the surface, its formula is composed by weight ratio, nylon 6 (relative viscosity 2.4, melt index 8g / 10min): 80%, alkali-free long glass fiber with aspect ratio of 100 Fiber: 10%, nano-calcium carbonate with a particle size of 1um: 3%, main flame retardant melamine: 2%, auxiliary flame retardant magnesium hydroxide: 1%, low-viscosity nylon 6 (relative viscosity 0.8, melt index 25g / 10min): 2%, glass fiber modifier γ-aminopropyltriethoxysilane: 1%, small molecule lubricant 1st generation PAMAM: 0.5%, antioxidant 2,6-tertiary butyl-4 - methyl phenol is 0.5%.

[0024] The preparation method of long glass fiber flame-retardant reinforced nylon 6 composite material with no fiber exposed on the surface comprises the following steps:

[0025] A. Put the glass fiber modifier γ-aminopropyltriethoxysilane and the alkali-free long glass fiber in the reaction kettle to react for 1 hour ...

Embodiment 2

[0029] Long glass fiber flame retardant reinforced nylon 6 composite material with no fiber exposed on the surface, its formula is composed of nylon 6 (relative viscosity 3.0, melt index 6g / 10min): 60%, alkali-free long glass fiber with aspect ratio of 150 Fiber: 25%, nano-calcium carbonate with a particle size of 3um: 8%, primary flame retardant ammonium polyphosphate: 3%, auxiliary flame retardant antimony trioxide: 1%, low-viscosity nylon 6 (relative viscosity 1.0, melting Index: 20g / 10min): 2%, glass fiber modifier γ-glycidyl etheroxypropyl trimethoxysilane: 0.5%, small molecule lubricant 2nd generation PAMAM: 0.3%, antioxidant 2,6-three Grade butyl-4-methylphenol is 0.2%.

[0030] The preparation method of long glass fiber flame-retardant reinforced nylon 6 composite material with no fiber exposed on the surface comprises the following steps:

[0031] A. Put the glass fiber modifier γ-glycidyl etheroxypropyltrimethoxysilane and the alkali-free long glass fiber in the rea...

Embodiment 3

[0035]Long glass fiber flame retardant reinforced nylon 6 composite material with no fiber exposed on the surface, its formula is composed by weight ratio, nylon 6 (relative viscosity 3.6, melt index 4g / 10min): 30%, alkali-free long glass fiber with aspect ratio of 300 Fiber: 50%, nano-calcium carbonate with a particle size of 10um: 10%, main flame retardant phosphate: 3%, auxiliary flame retardant aluminum hydroxide: 0.5%, low-viscosity nylon 6 (relative viscosity 1.6, melt index is 15g / 10min): 5%, glass fiber modifier γ-mercaptopropyl trimethoxysilane: 0.8%, small molecule lubricant 3rd generation PAMAM: 0.4%, antioxidant 2,6-tertiary butyl-4 - methyl phenol is 0.3%.

[0036] The preparation method of long glass fiber flame-retardant reinforced nylon 6 composite material with no fiber exposed on the surface comprises the following steps:

[0037] A. Put the glass fiber modifier γ-mercaptopropyltrimethoxysilane and the alkali-free long glass fiber in the reaction kettle for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com