Manufacturing process flow of square microneedle massager

A technological process and massager technology, applied in the directions of micro-needles, needles, medicines, etc., can solve the problems of inconvenient disinfection and cleaning, hidden dangers, high product prices, etc., achieve thorough disinfection and cleaning, improve practical effects, and appearance. Smooth and neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

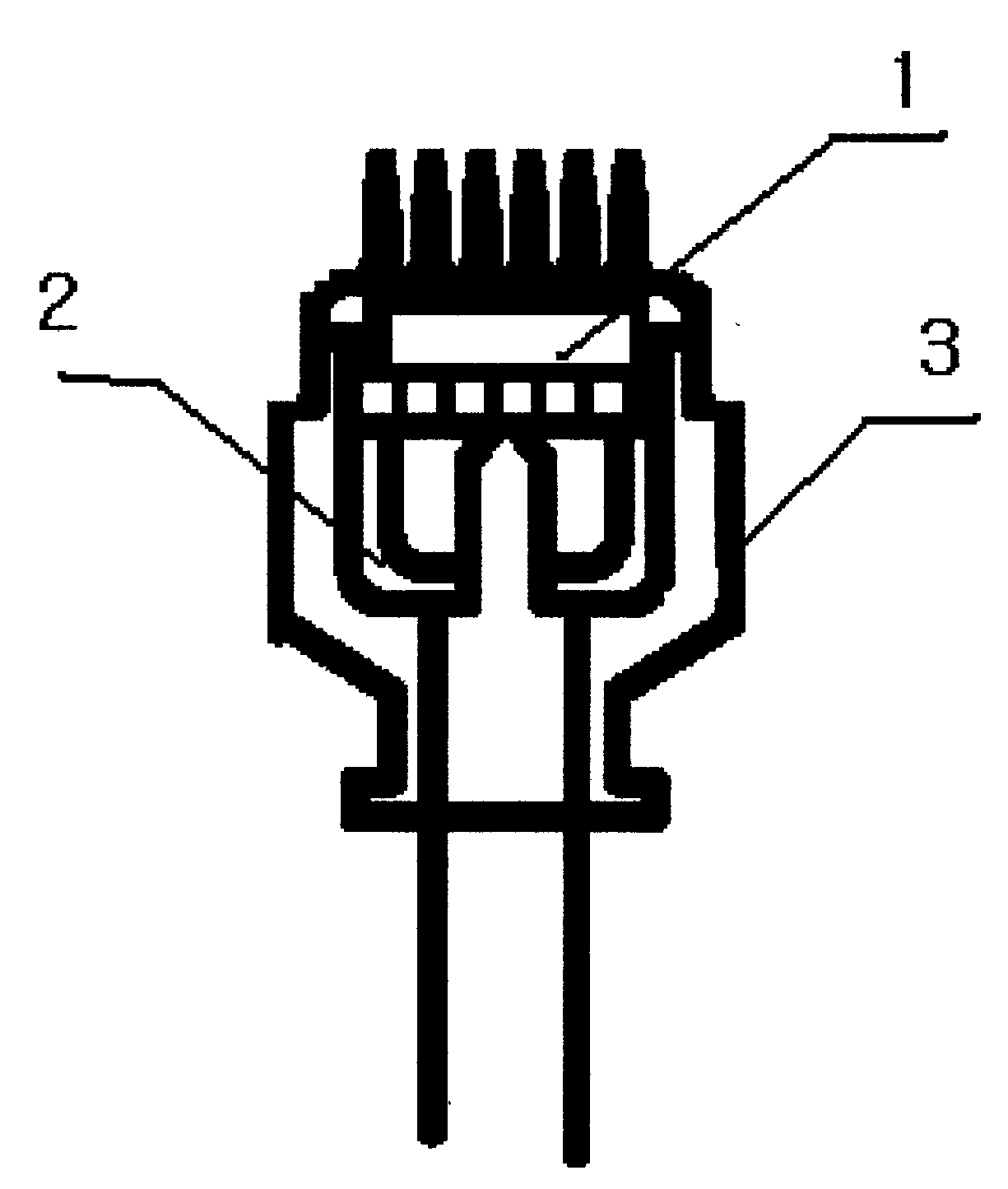

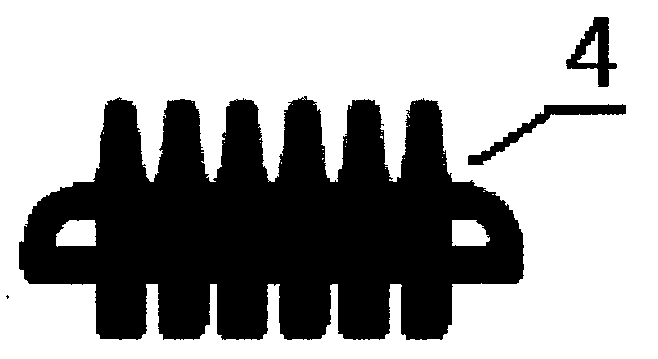

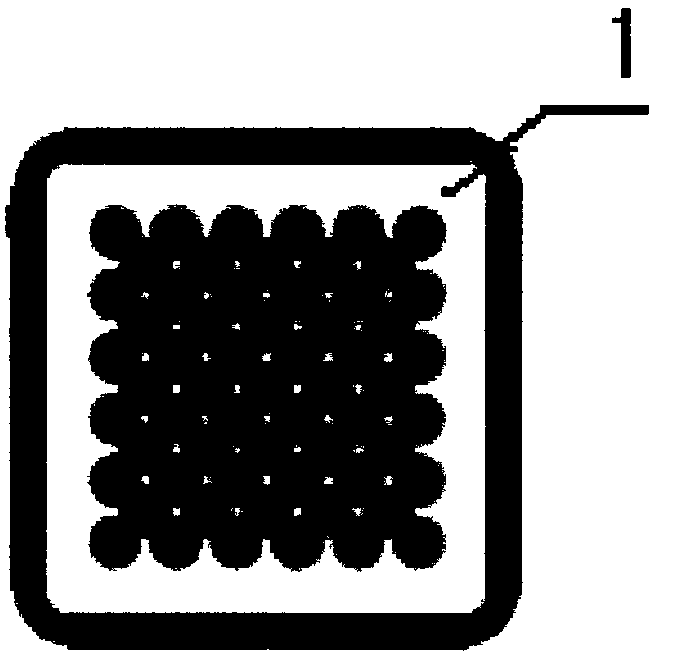

[0025] see Figure 1 to Figure 4 As shown, the present invention includes a square microneedle massager structure and its manufacturing process. The square microneedle massager structure includes a plastic needle piece set 1, a square cover 2 and a protective cover 3. The plastic needle piece set 1 is internally provided with a plastic Needle sheet 4 and hole shell 5, the plastic needle sheet 4 includes several pinholes with the same row spacing and several air holes with the same row spacing, the rows where the pinholes are located and the rows where the air vent holes are located are arranged alternately, and the hole shell is provided with several Square holes with the same row spacing, the square holes are the same as the air vent holes on the plastic needle sheet 4 and communicate with each other, the hole shell 5 is embedded in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com