Preparation method of polyurethane synthetic leather for soft-suede high-elasticity leather-imitated sofa furniture

A high-elasticity, artificial leather technology, applied in furniture parts, home appliances, applications, etc., can solve the problems of obvious incision wet material layer, poor leather feeling, poor drape feeling, etc., to achieve a delicate, soft and plump touch and strong drape feeling. , the effect of small wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of polyurethane synthetic leather for soft suede high elasticity imitation leather sofa furniture, comprising the following steps:

[0036] (1) Use suede elastic fiber synthetic cloth base as raw material, the plush side of suede elastic fiber synthetic cloth base as the front, and the short-pile suede side of suede elastic fiber synthetic cloth base as the back, using wet process, impregnated and water-resistant Depolyether polyurethane impregnating slurry is formed at one time. The wet process is to impregnate the cloth base with hydrolysis-resistant polyether polyurethane impregnating slurry. Use a scraper to trim the excess slurry on the long-pile surface, and then use a sharp knife to modify the short-pile surface before condensing in water. Finally, water coagulation, water washing, and drying. The wet method adopts a one-time molding process of knife-scraping and impregnating polyether-type hydrolysis-resistant polyurethane slurry. Before wate...

Embodiment 1

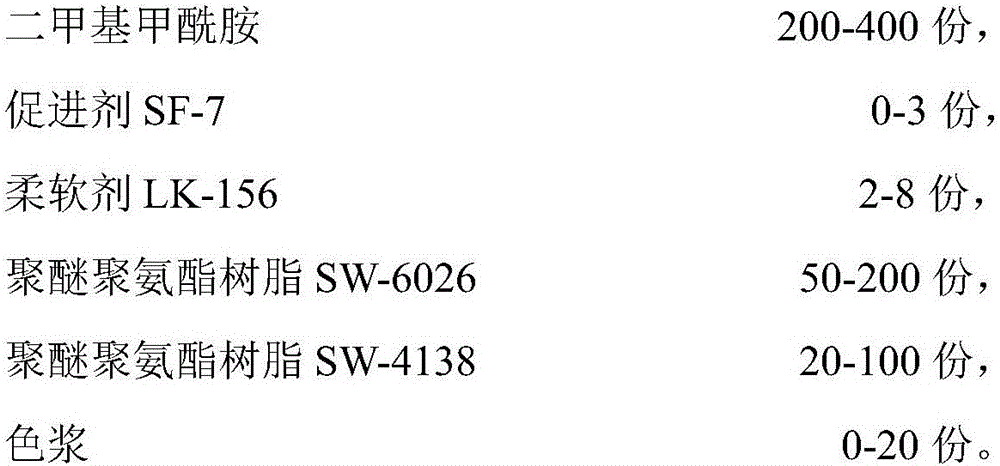

[0060] The raw materials of polyether polyurethane impregnating slurry are composed as follows by mass:

[0061]

[0062]

[0063] In the three-knife slurry of dry veneer:

[0064] Flour: 180kg of polyester polyurethane resin ST-2066, 0.5kg of anti-wear additive 3238 solution, 2kg of PU white;

[0065] Two-knife slurry: polyester polyurethane resin ST-2066 180kg, PU white 2kg

[0066] Adhesive paste: polyester polyurethane resin SA-36 90kg, solvent ETAC 30kg, curing agent 2681kg

[0067] The viscosity of the polyether polyurethane impregnation slurry is 600cps, the temperature is 25°C, the scraping gap is 0.15mm, the sharp knife is scraped and modified before entering the water, and the angle between the sharp knife and the leather surface is 90°. The solidification condition is that the temperature is 30°C, and the concentration of the DMF solution is 26wt%,

[0068] In step (1), the washing temperature is 40°C-50°C, and the temperature is 120°C-140°C when drying in ...

Embodiment 2

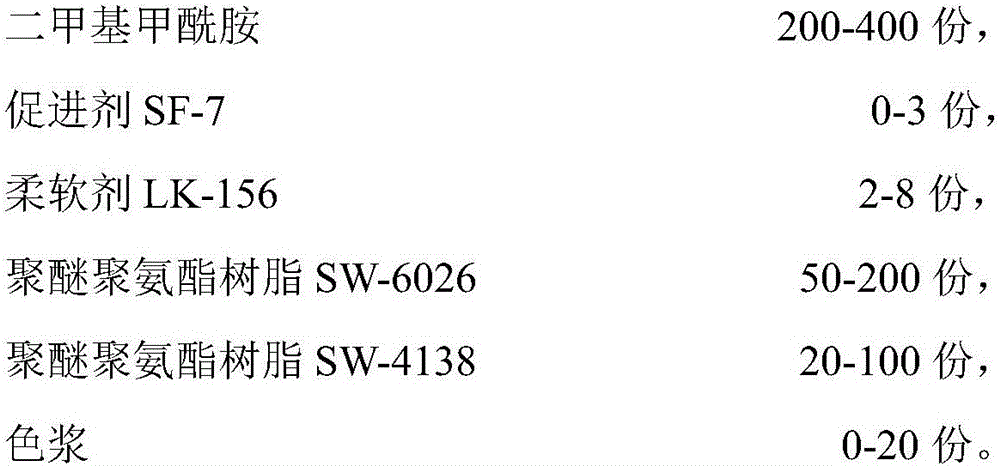

[0073] The raw materials of polyether polyurethane impregnating slurry are composed as follows by mass:

[0074]

[0075] In the three-knife slurry of dry veneer:

[0076] Flour: 150kg polyester polyurethane resin ST-2066, 0.5kg anti-wear additive 3238 solution, PU white 2kg;

[0077] Two-knife slurry: polyester polyurethane resin ST-2066 150kg, PU white 2kg

[0078] Adhesive paste: polyester polyurethane resin SA-36 100kg, solvent ETAC 30kg, curing agent 2681kg

[0079] Other processing conditions are as embodiment 1.

[0080] The peeling strength of polyurethane synthetic leather for artificial leather sofa furniture produced in the above examples reaches 40N / 3cm, the durability reaches 3 years, and the bending at room temperature reaches 100,000 times without breaking. Plump, with a strong granular feel on the back, a delicate, soft and plump touch, a strong leather feel, and a very high cost performance.

[0081] Remarks: Accelerator SF-7 is Jiande Shunfa Chemical A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com