Composite modification method for lithium ion battery positive electrode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as serious side reactions, poor structural stability, and air moisture sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

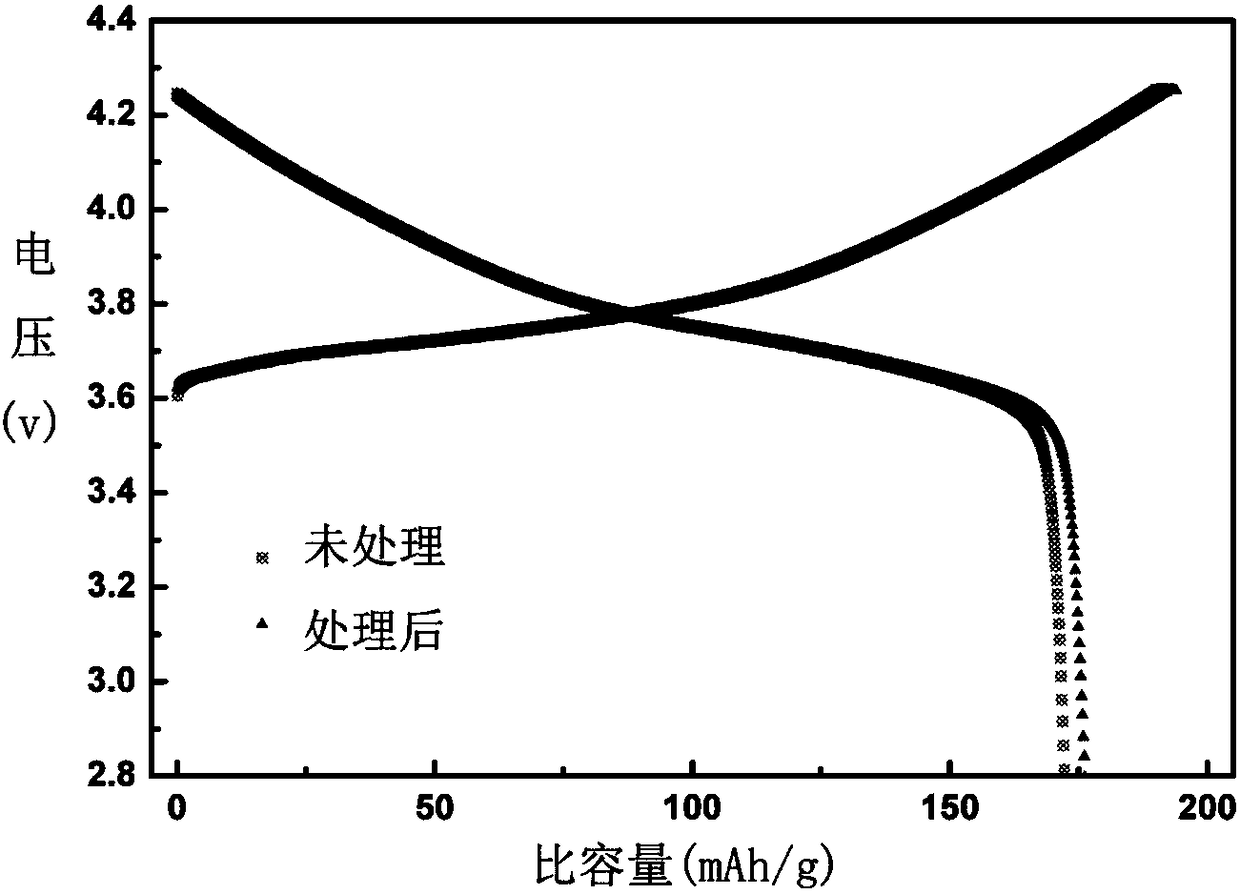

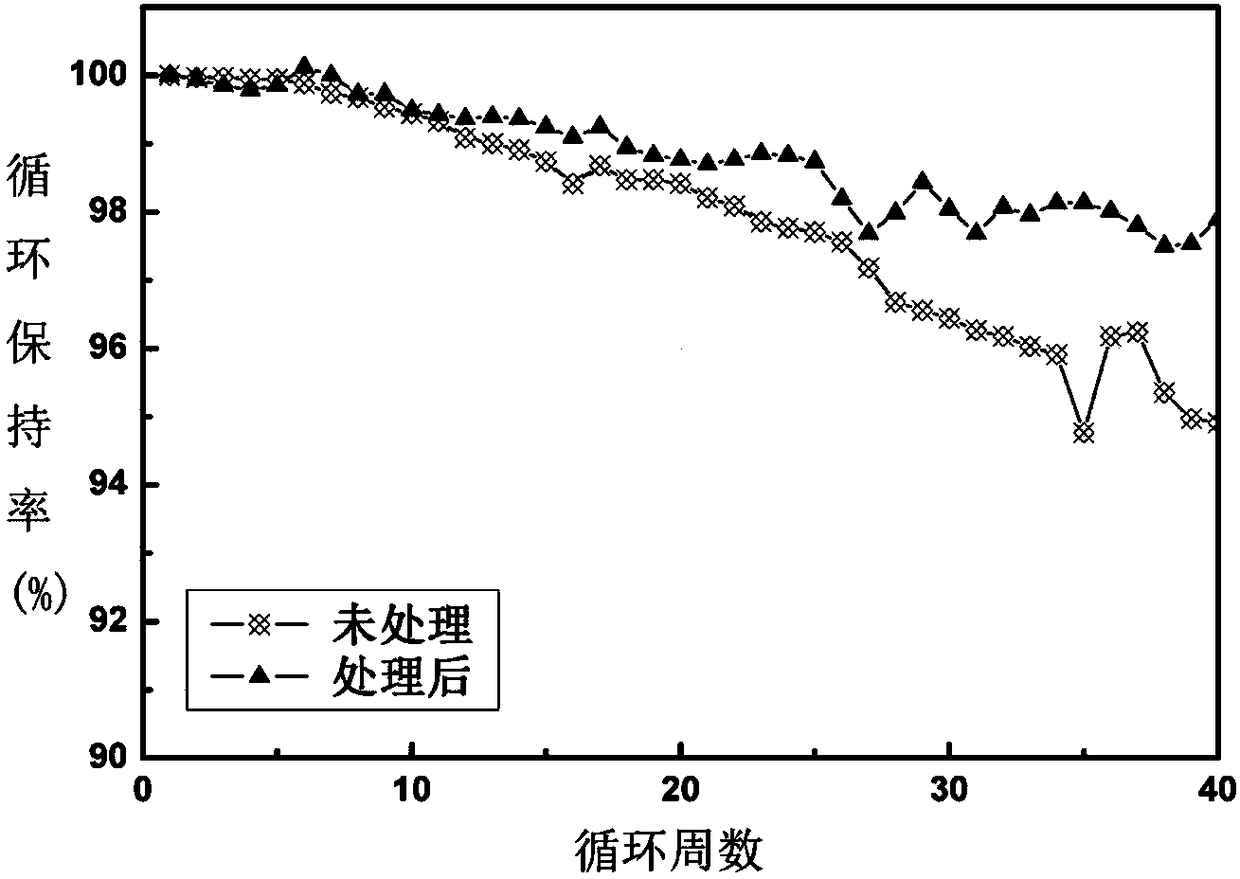

Embodiment 1

[0065] (1) Synthesis of high-nickel precursor Ni by co-precipitation technology 0.6 co 0.2 mn 0.2 (OH) 2 , after washing, drying or heat treatment, the Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor products.

[0066] (2) The precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 The product and the lithium source are thoroughly mixed, wherein the molar ratio of lithium:transition metal (Ni, Co, Mn) is 1.05.

[0067] (3) Raise the fully mixed precursor substance to 900°C at 1.5°C / min in an oxygen atmosphere, and keep it for 15h to obtain the untreated matrix high-nickel cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 .

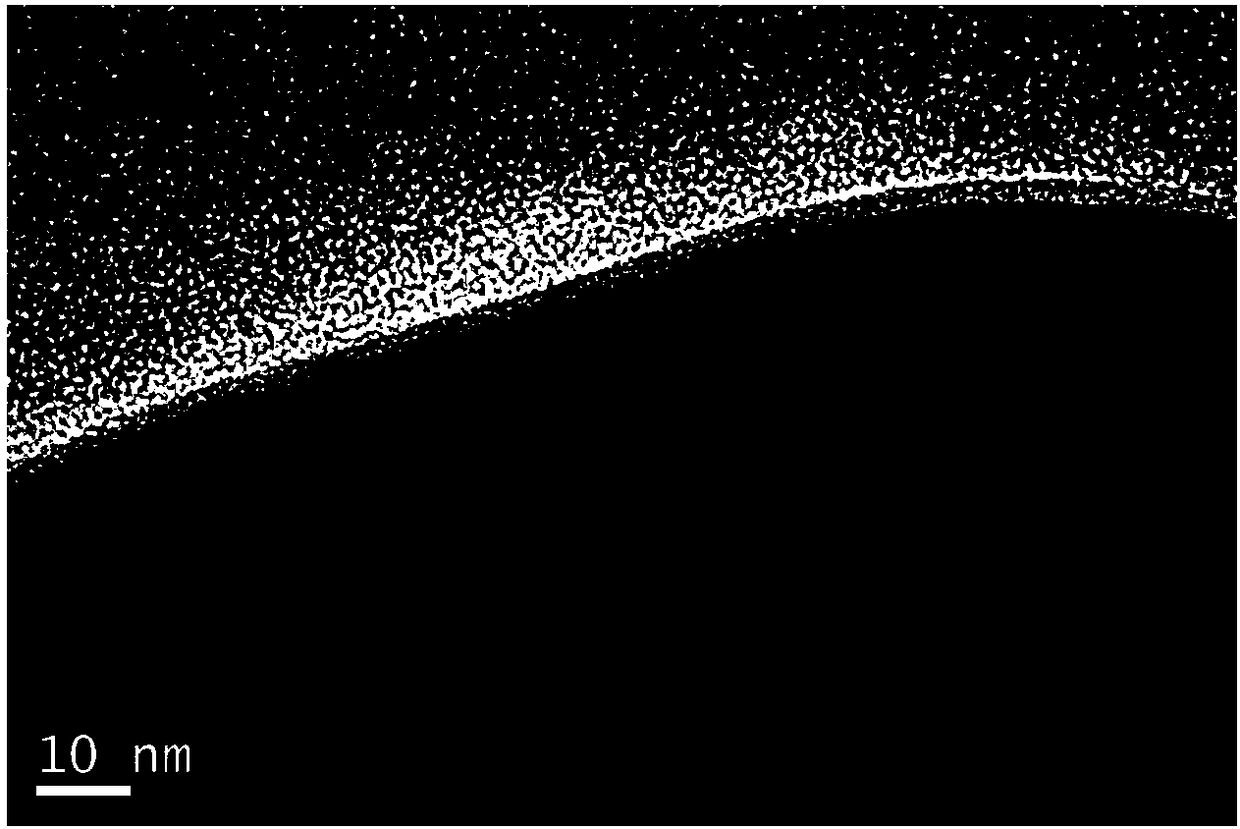

[0068] (4) the source material TiO of the material to be coated 2 , the coating auxiliary agent ethylene glycol is dispersed in ethanol and fully dissolved, wherein, the coating amount is 0.2-0.5wt.%, the mass ratio of the coating material and the solvent is 1:100, and the matrix material LiNi 0.6 co 0.2 mn 0.2 o 2 After being added into the dispersion system, stirred a...

Embodiment 2

[0076] (1) Synthesis of high-nickel precursor Ni by co-precipitation technology 0.6 co 0.2 mn 0.2 (OH) 2 , after washing, drying or heat treatment, the Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor products.

[0077] (2) The precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 The product and the lithium source are thoroughly mixed, wherein the molar ratio of lithium:transition metal (Ni, Co, Mn) is 1.05.

[0078] (3) Raise the fully mixed precursor substance to 900°C at 1.5°C / min in an oxygen atmosphere, and keep it for 15h to obtain the untreated matrix high-nickel cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 .

[0079] (4) The source material Al of the material to be coated 2 o 3 , the coating auxiliary agent ethylene glycol is dispersed in ethanol and fully dissolved, wherein, the coating amount is 0.2-0.5wt.%, the mass ratio of the coating material and the solvent is 1:100, and the matrix material LiNi 0.6 co 0.2 mn 0.2 o 2 After adding it into the dispersion system, stirrin...

Embodiment 3

[0085] (1) Synthesis of high-nickel precursor Ni by co-precipitation technology 0.8 co 0.1 mn 0.1 (OH) 2 , LiNi that can be used for sintering synthesis is obtained after washing, drying or heat treatment. 0.8 co 0.1 mn 0.1 o 2 precursor products.

[0086] (2) The precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 The product is fully mixed with lithium sources, wherein the molar ratio of lithium:transition metals (Ni, Co, Mn) is 1.05.

[0087] (3) Raise the fully mixed precursor material to 800°C at 1.5°C / min in an oxygen atmosphere, and keep it for 15h to obtain the untreated matrix high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 .

[0088] (4) The source material aluminum isopropoxide of the material to be coated, and the coating auxiliary agent ethylene glycol are dispersed in ethanol and fully dissolved, wherein, Al 2 o 3 The coating amount is 0.2-0.5wt.%, the mass ratio of the coating material and the solvent is 1:100, and the matrix material LiNi 0.8 co 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com