Glass material preparation crucible and preparation method

A glass and crucible technology, which is applied in the field of optical glass melting production equipment, can solve problems such as platinum crucible wall erosion, and achieve the effect of avoiding service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

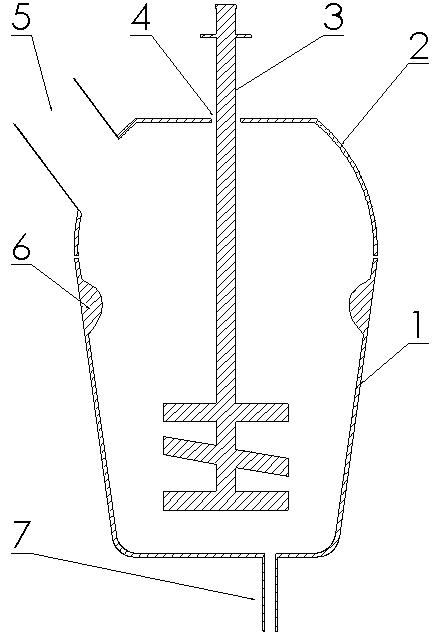

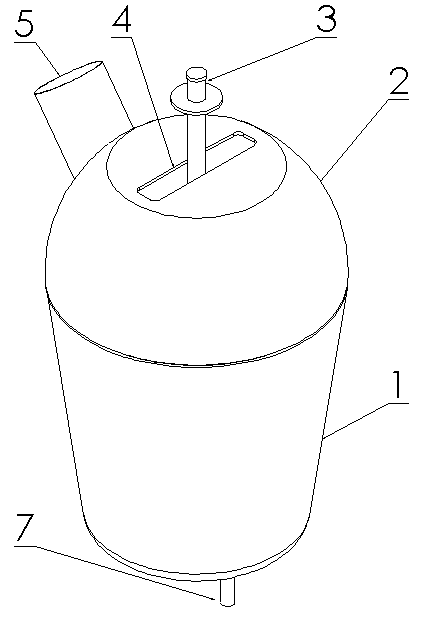

[0036] Such as figure 1 , 2 , using Al 2 o 3 20%, ZrO 2 ≥73%, SiO 2 Each part of the crucible is made of 5% ceramic material. The crucible body 1 adopts an open type, and the crucible cover 2 adopts an arc closed design. The angle of the feeding port 5 is obliquely upward. 4 is a rectangle, and the minimum distance between its minor axis direction and the stirring rod is 1 cm. After the implementation, the loss of fluorine-containing components in the product was significantly reduced, the upper limit of single-pot smelting was 35 crucibles, and the platinum foreign matter inside the product was reduced from 1.2 pieces / cm 3 down to 0.05 / cm 3 .

Embodiment B

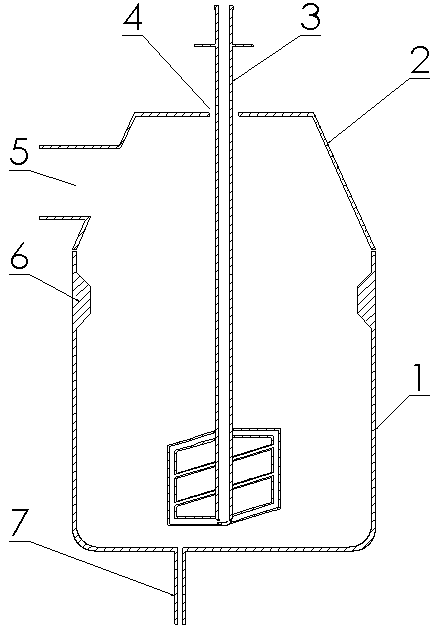

[0038] Such as image 3 , using Al 2 o 3 ≥80%, ZrO 2 15%, SiO 2 The parts of the crucible are made of 4% ceramic materials. The crucible body 1 adopts a vertical type, the crucible cover 2 adopts a straight and closed design, the feeding port 5 is angled horizontally, the stirrer adopts a hollow "frame" design, and the stirring hole 4 It is elliptical, and the minimum distance between its short axis direction and the stirring rod is 1cm. After the implementation, the loss of fluorine-containing components in the product was significantly reduced, the upper limit of smelting in a single pot was 42 crucibles, and the platinum foreign matter inside the product was reduced from 1.2 pieces / cm 3 down to 0.03 / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com