Device and method for spraying carbon to deoxidize by using slag stopping system

A technology of carbon injection and slag blocking cone, which is applied in the direction of manufacturing converters, etc., can solve the problems of nozzle erosion, shorten the service life of the tapping hole, increase the tapping hole and other problems, so as to solve the construction difficulty, reduce the construction difficulty and ensure the The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

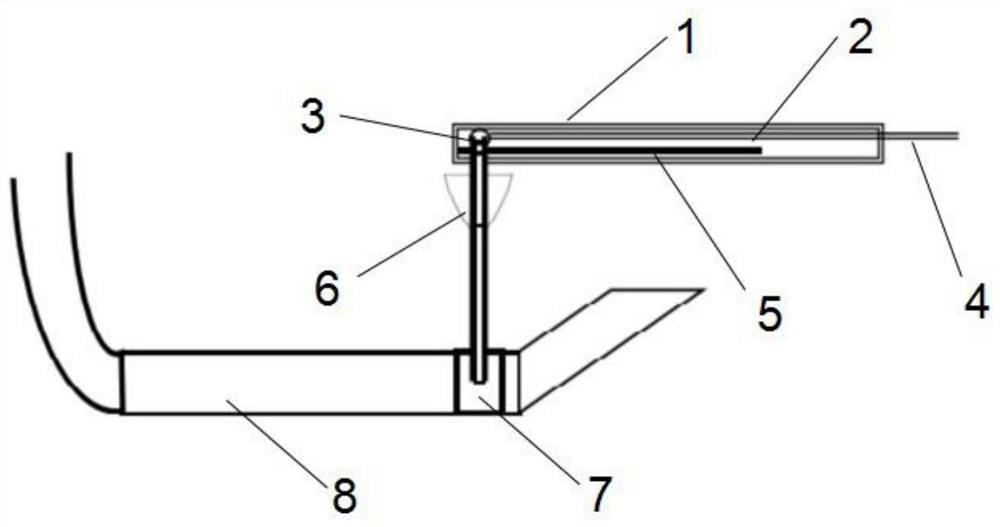

[0044] like figure 1 , figure 2 As shown, a device for carbon spraying and deoxidation using a slag blocking system, including a slag blocking cone truck arm 1 and a slag blocking cone 6, and a powder delivery pipeline 2 and a clamping device are provided inside the slag blocking cone truck boom 1 pipeline 5. The position of the slag blocking cone 6 is fixed by the clamping device 5 , and the front end of the powder conveying pipeline 2 is connected to one end of the rotary joint 3 .

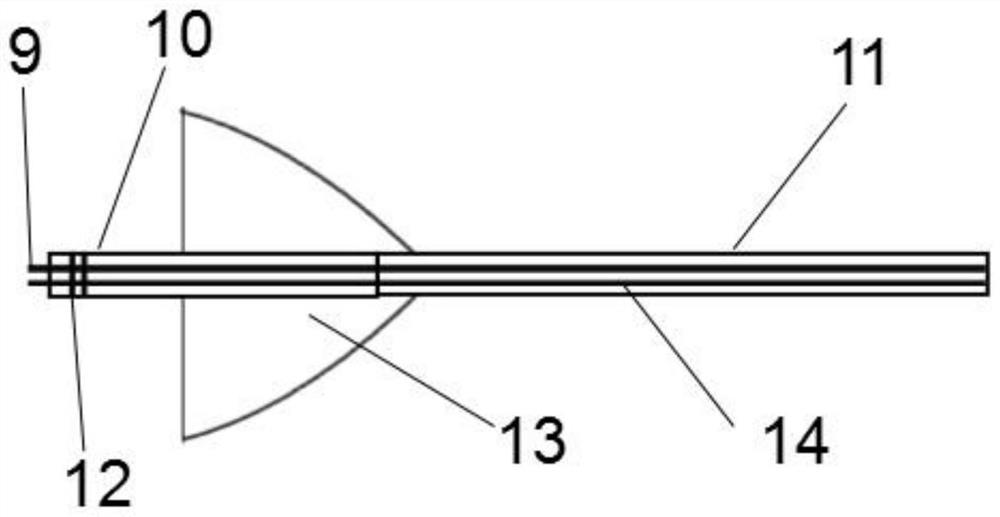

[0045] The center of the slag blocking cone 6 is a single-layer nozzle with a clamping slot 12. The slag blocking vehicle and the slag blocking cone pass through the powder delivery pipeline 2 in the middle of the boom and the spray pipe 14 at the center of the slag blocking cone. The joint 3 is closely matched, the cone head 13 is positioned by clamping the outer pipe 10 of the slag-stopping cone rod, and the head of the central pipe is connected with the outer pipe by spot welding.

[0046]...

Embodiment 2

[0055] In this embodiment, the method is applied to 100 tons of steelmaking. The inner diameter of the injection pipe in the slag blocking cone and cone rod is 16 mm. The deoxidizing powder uses carbon powder with a diameter of less than 1 mm. Kind of HRB400E, select the carrier gas as nitrogen, and the injection powder as carbon powder.

[0056] A method for deoxidizing by carbon spraying using a slag blocking system, comprising the following steps:

[0057] Step 1) According to the control of 0.07% carbon content at the end point of the converter end point prediction system, the oxygen content of molten steel according to previous data statistics is 530ppm. Calculated at 280ppm, the oxygen content to be removed is 250ppm, the amount of carbon powder to be injected is controlled at 1.4kg / t, and 140kg of carbon powder after weighing is added to the powder spray tank, combined with the effective time of spraying on the furnace and the injection material Volume, preset powder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com