Method for preparing solid calcium carbide

A calcium carbide, solid-state technology, applied in the chemical industry, can solve the problems of poor heat conduction, not reducing the energy consumption of calcium carbide production, difficult to achieve in industrial production, etc., to increase the specific surface area and contact area, promote mass transfer and heat transfer efficiency, and reduce the reaction. The effect of activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

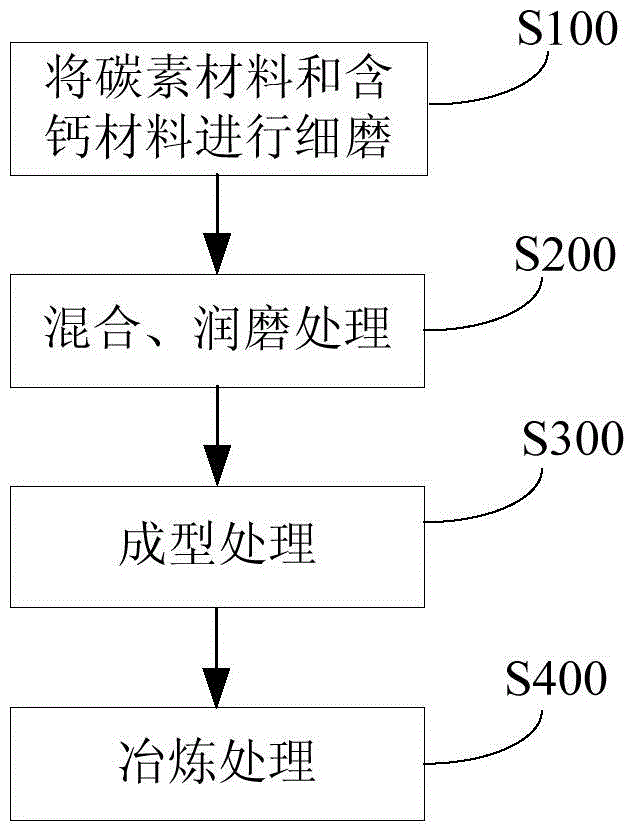

Image

Examples

preparation example Construction

[0041] According to the method for preparing solid calcium carbide according to the embodiment of the present invention, the carbon material and the calcium-containing material are finely ground to obtain ultra-fine-grained materials, which can increase the specific surface area and contact area of the material, thereby significantly reducing the activation energy of the reaction in the smelting process. In this way, the production efficiency of calcium carbide can be improved. At the same time, by adding iron powder to the mixed material, it can promote the local generation of a small-scale liquid phase during the smelting process, thereby improving the efficiency of mass transfer and heat transfer. In addition, by strictly controlling the smelting temperature in the material pellet system Below the melting point temperature, the pellets only shrink without softening and melting during the entire smelting process, thus preparing solid calcium carbide, thus avoiding the proble...

Embodiment 1

[0047] The semi-coke and the quicklime are finely ground respectively to obtain the semi-coke powder and the quicklime powder whose average particle size is less than 30 microns and account for more than 98.19%. The industrial analysis of the semi-coke is shown in Table 1, and the CaO content of the quicklime is 90.89wt%, then the blue charcoal powder, quicklime powder and iron powder are transported in the batching tank through gas, and are quicklime powder according to the weight ratio: blue charcoal powder: iron powder=100:85:9 mix, obtain mixture, wherein, The average particle size of the iron powder is not higher than 74 microns and the total iron content is 89.16wt%. Then the prepared mixture is sent to the moistening mill by the airflow, and a water pipe is used to add part of the Molasses (the rotating speed of the moistening mill is 33r / min, and the medium filling rate is 12%) is moistened for 10 minutes to obtain a mixed material, and then the obtained mixed material ...

Embodiment 2

[0052] The anthracite and quicklime with a particle size below 1 mm are finely ground respectively to obtain anthracite powder and quicklime powder with an average particle size of less than 10 microns accounting for more than 95%. Among them, the industrial analysis of anthracite is shown in Table 2. The content is 90.89wt%, then anthracite powder, quicklime powder and iron powder are transported into the batching tank through gas, and mixed according to the weight ratio of quicklime powder: anthracite powder: iron powder=100:85:9 to obtain a mixture, wherein iron The average particle size of the powder is not higher than 74 microns, and then the prepared mixture is sent to the lubricating mill by the air flow, and a part of hot high-temperature asphalt is added to the lubricating mill by using a water pipe at the feeding part of the lubricating mill (the temperature of the asphalt is at 150 ℃, the rotating speed of the moistening mill is 33r / min, the medium filling rate is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas output | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com