Method of shallow reinforcement and surface reinforcement of loess slope

A technology for slopes and shallow layers, applied in soil protection, excavation, infrastructure engineering, etc., can solve problems such as weathering and peeling, rainfall erosion, long construction period, etc., achieve good elasticity, enhance stability, and solve the effects of weathering and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Shallow layer reinforcement and surface layer consolidation of the loess slope in the open-air reservoir of Zhongwei City, Ningxia

[0028] Shallow anti-seepage reinforcement of the loess slope of the open-air reservoir in Zhongwei City, Ningxia Autonomous Region. The slope is 4m high and the slope ratio is 1:0.6. The slope is seriously weathered and peeled off. It belongs to the north temperate continental monsoon climate, with an annual average temperature of 8.4°C, a minimum temperature of -20°C, and a maximum temperature of 33°C. According to the soil conditions of the silty loess, the reinforcement steps are as follows:

[0029] 1. Slope cleaning. The weathered loose layer on the surface of the slope is cleaned by a combination of manual and mechanical methods.

[0030] 2. Excavate and cut drainage ditches. The intercepting ditch will be excavated at the outer edge of the slope. The cross section of the intercepting ditch is a natural curved side ditc...

Embodiment 2

[0036] Example 2: Shallow reinforcement and surface consolidation of loess slopes on highways in a city in Ningxia

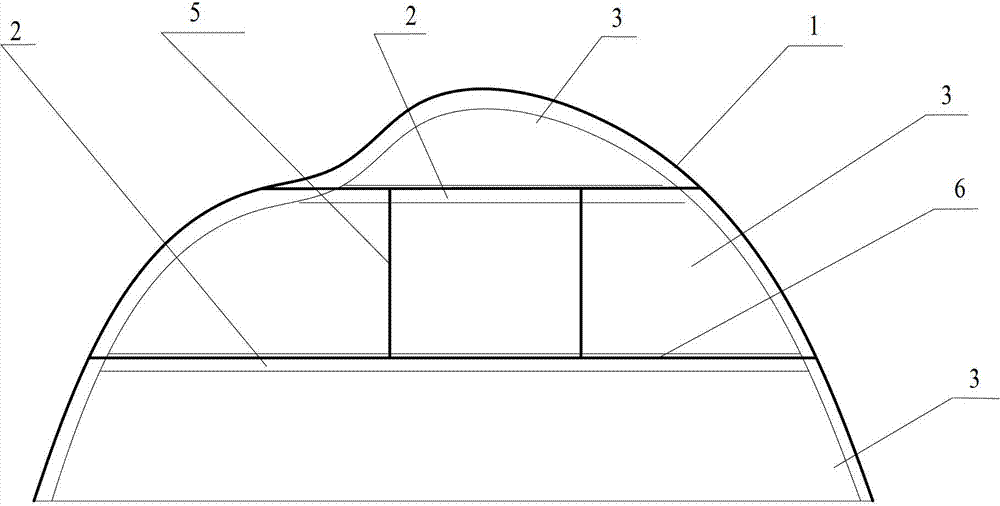

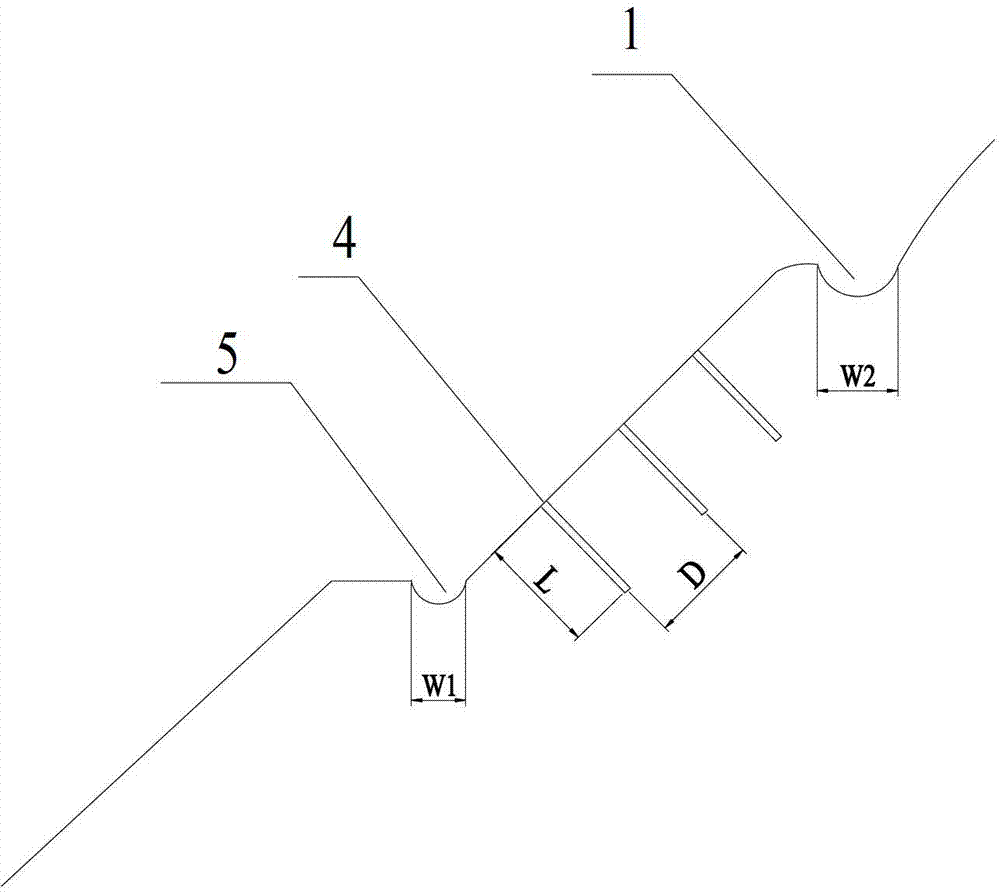

[0037] The slope is a third-grade slope, and the weathering and spalling of the slope is serious. For the soil conditions of the silty loess, the reinforcement steps are as follows (see figure 1 and figure 2 ):

[0038] 1. Slope cleaning. The weathered loose layer on the surface of the slope 3 is cleaned by a combination of manual and mechanical methods.

[0039] 2. Excavate and cut drainage ditches. The intercepting ditch 1 is excavated at the outer edge of the slope. The section of the intercepting ditch 1 is a natural arc-shaped side ditch with a width W2 of 60 cm and a depth of 40 cm. Excavate the horizontal drainage ditch 6 of the platform on the inner side of the platform. The cross section of the horizontal drainage ditch is a natural arc side ditch with a width of 50cm and a depth of 30cm. Excavate the longitudinal drainage ditches 5 at intervals ...

Embodiment 3

[0045] Example 3: Reinforcement of Silty Loess Slope on a Highway in Gansu Province

[0046] The annual average temperature of the place is 11.5°C, and the annual minimum temperature is -20°C.

[0047] The slope is a secondary road slope, with a slope area of 7,580 square meters, a primary slope height of 8m, a secondary slope height of 6.5m, a slope ratio of 1:0.75, and a platform width of 2.5m.

[0048] The slope reinforcement steps include:

[0049] 1. Use a combination of manual and mechanical methods to clean the weathered loose layer on the surface of the slope to keep the slope smooth.

[0050]2. Excavate and cut drainage ditches. The intercepting ditch is excavated at the outer edge of the slope. The section of the intercepting ditch is a natural arc side ditch with a width of 80cm and a depth of 45cm. Excavate horizontal drainage ditches on the inner side of the platform. The section of the drainage ditch is a natural arc-shaped side ditch with a width of 50cm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com