High-pressure flow rotating and filtering type natural gas sand remover

A high-pressure swirling, filtering technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve problems such as pipeline and storage tank blockage, ground gate failure, valve core pitting, etc., and achieve considerable economical benefits. Benefit, prevent blockage of pipeline or equipment, solve the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

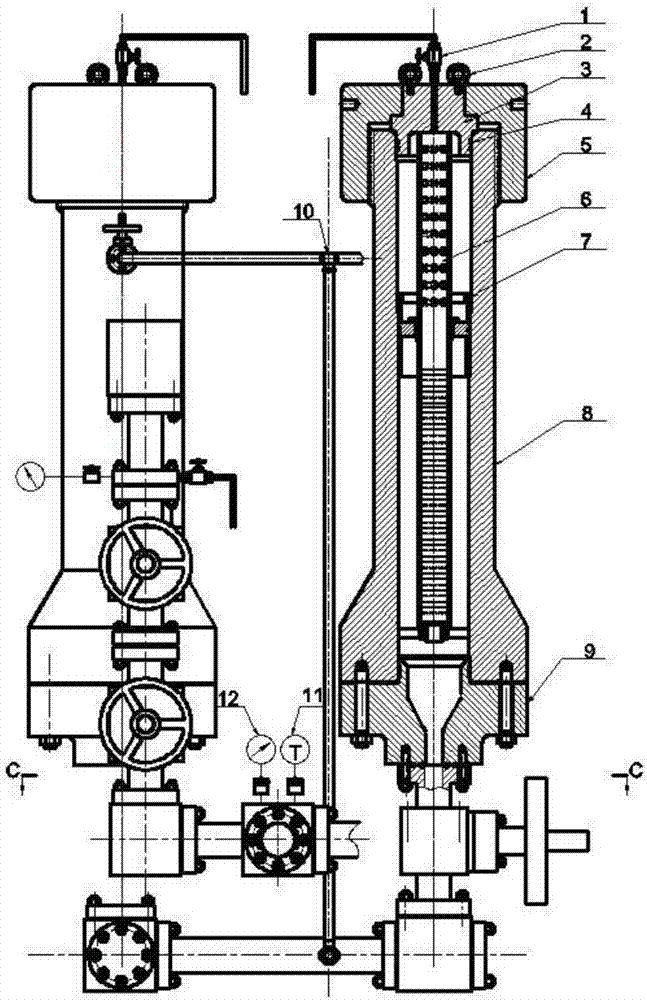

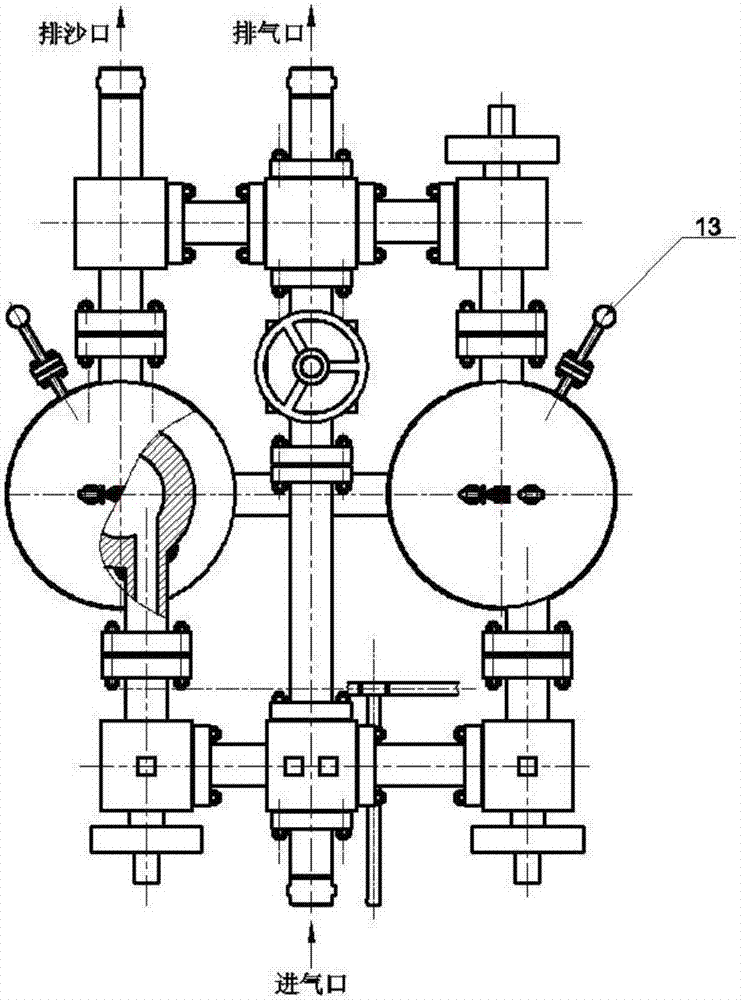

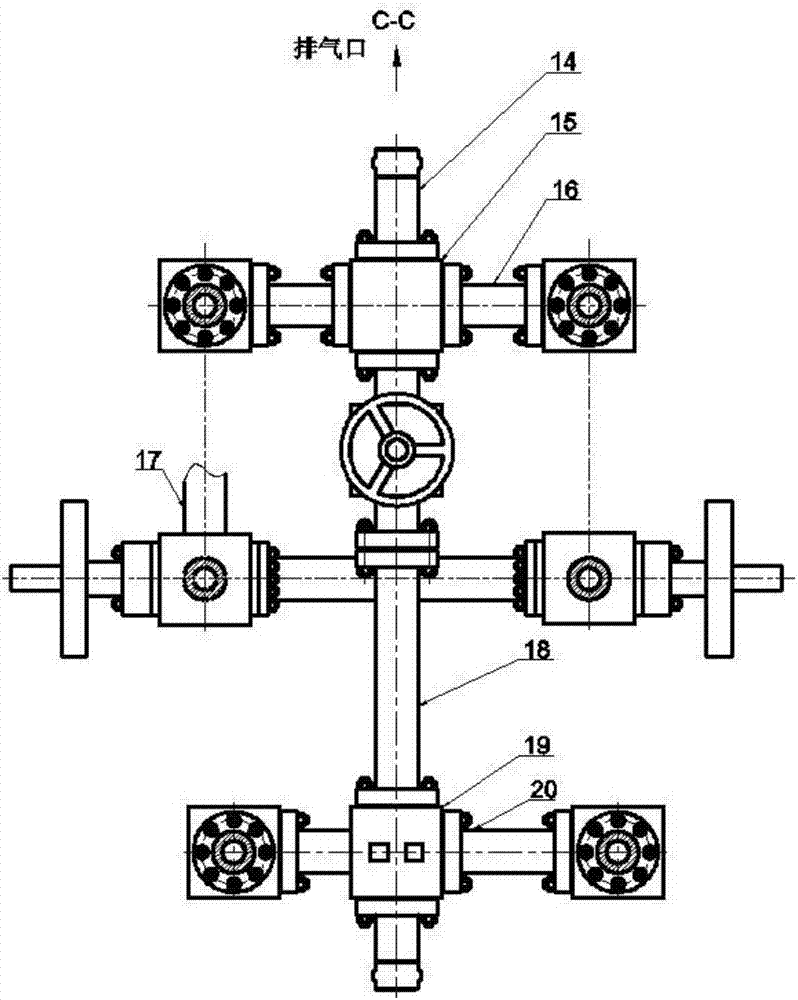

[0019] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0020] Such as Figure 1-Figure 6As shown, the high-pressure cyclone filter type natural gas desander device of the present invention includes six parts: a desander device, a pipeline system, a mounting frame, a worm gear lifting device 26, a backwash device 21, and a high-pressure liquid volume metering device 13. Pressure valve 1, lifting lug 2, plug cap 3, combined sealing ring 4, nut 5, filter cartridge 6, wear-resistant sleeve 7, cylinder body 8, base flange 9, backwash pipeline tee 10, Pressure thermometer 11, pressure gauge 12, high-pressure liquid volume metering device 13, air outlet connecting pipe 14, air outlet cross 15, horizontal air outlet pipe 16, sand discharge pipe 17, bypass pipe 18, air inlet cross 19, horizontal air inlet Pipe fitting 20, backwashing device 21, middle beam 22, pedal 23, hoop 24, escalator 25, worm gear lifting device 26, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com