Carbon fiber continuous sucker rod provided with continuous flocculent wear-resistant layer internally

A wear-resistant layer and carbon fiber technology, which is applied in drill pipes, drilling equipment, earth-moving drilling, etc., can solve the problems of limited dipping performance of fibers or fabrics, discounted wear-resistant performance of wear-resistant materials, and poor degree of bonding and immersion. Achieve the effect of increasing splitting resistance and shear resistance, improving wear resistance, and increasing immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

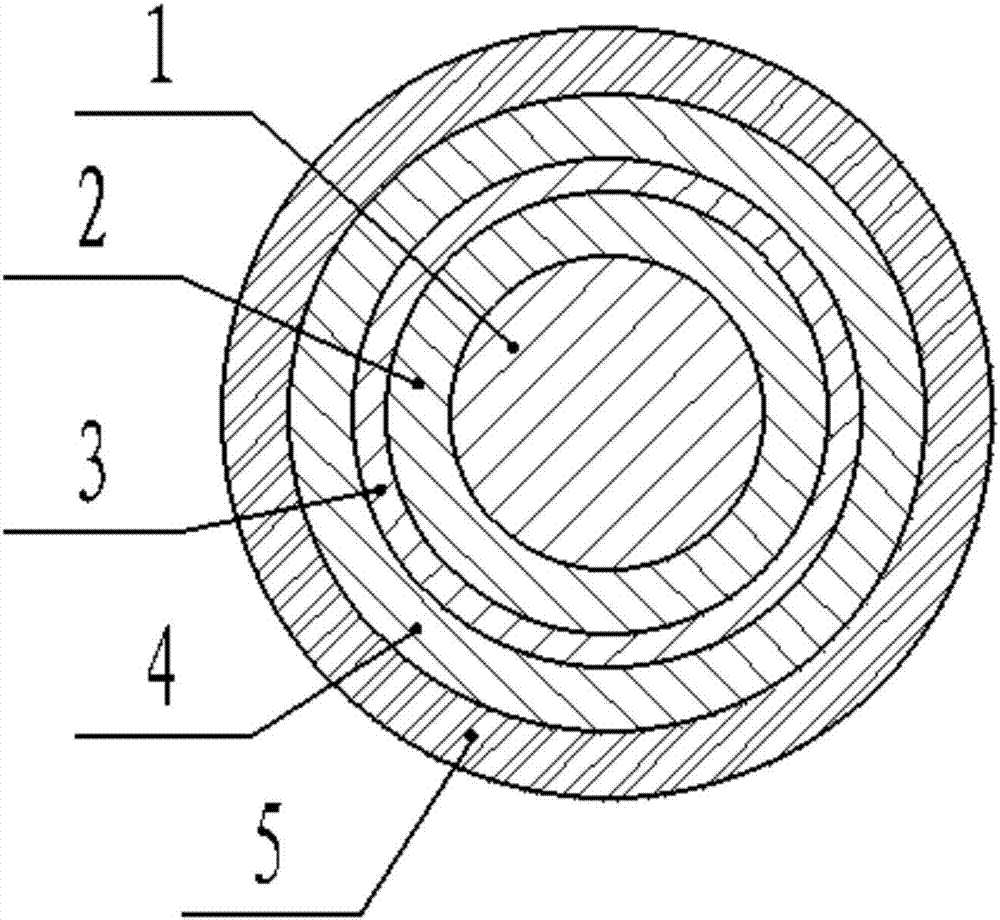

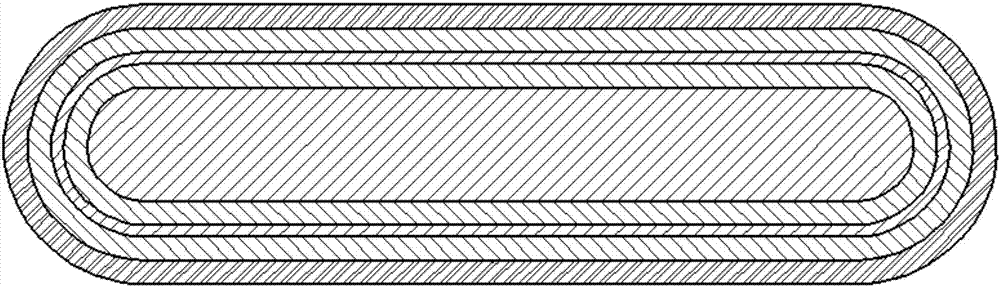

[0027] This embodiment includes a carbon fiber core 1, a wear-resistant layer 3 and an epoxy resin layer 5, which is the basic structure of a carbon fiber sucker rod in the prior art.

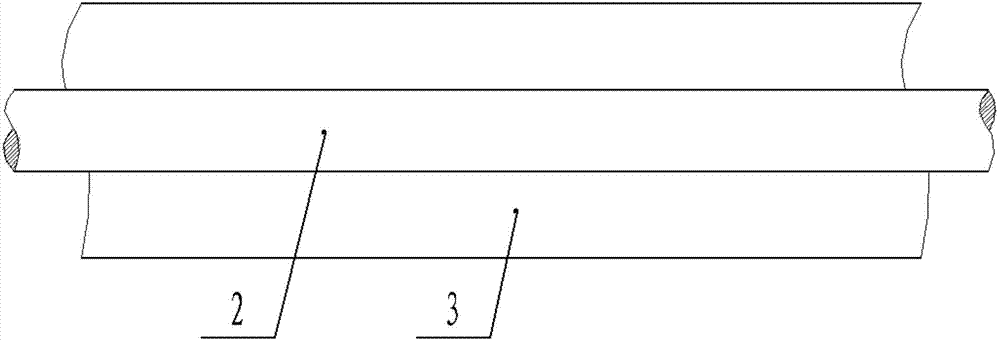

[0028] A roving layer 2 is arranged on the outside of the carbon fiber core 1, a wear-resistant layer 3 is arranged on the outside of the coarse sand layer 2, a spun layer 4 is arranged on the outside of the wear-resistant layer 3, and the epoxy resin layer 5 is arranged on the spun layer 4 outside. Among them, the role of the carbon fiber core 1 is to bear most of the tensile load; the role of the roving layer 2 and the spun layer 4 is to share the tensile load with the carbon fiber core 1, reduce the amount of carbon fiber, thereby reducing the production cost of the sucker rod, and at the same time , the aramid fibers that make up the roving layer 2 and the spun layer 4 have good wear re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com