Design method and production technology of multi-layer heat preserving shell fabric

A design method and fabric technology, applied in the direction of multi-strand fabrics, textiles, fabrics, etc., can solve the problems of non-washable, limited heating effect, strong heat conduction, etc., and achieve the effects of avoiding splitting, increasing production difficulty, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] 1. Product design and specification

[0034] 1.1 Fabric design:

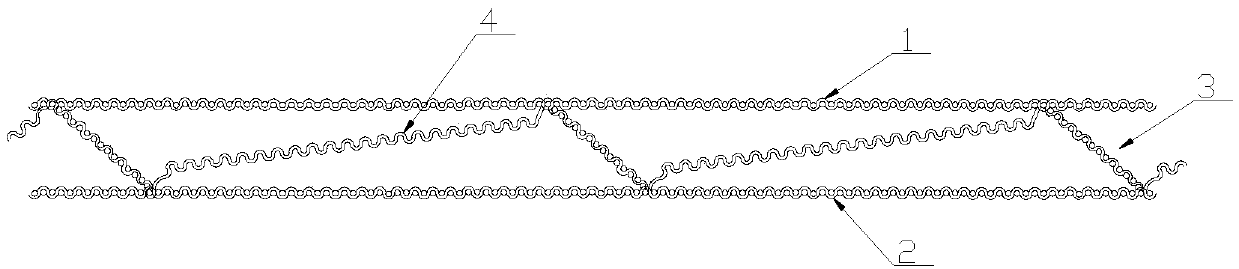

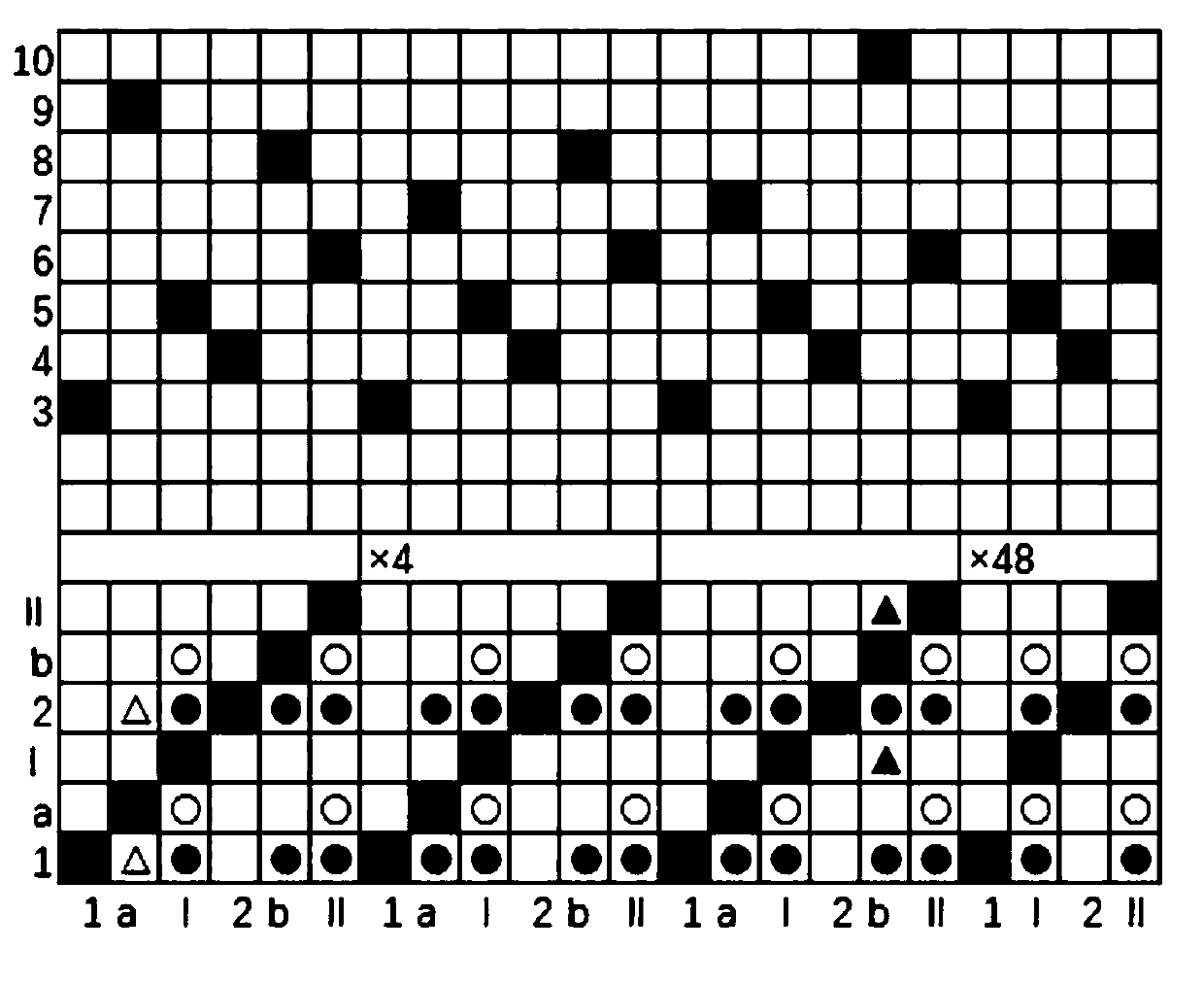

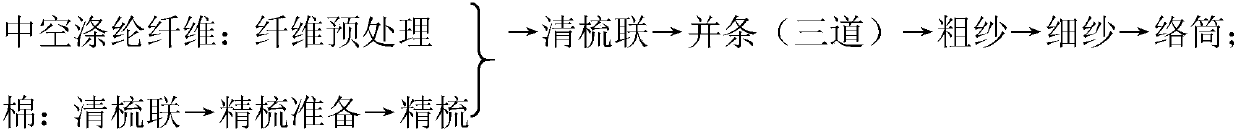

[0035] (1) The organizational structure of the fabric and the selection of raw materials. Such as figure 1 As shown, the fabric is a three-layer structure, and the warp and weft yarns of the surface layer 1 fabric are polyimide fibers and hollow polyester fiber Siro compact spinning; PI / T18.5tex, wherein the ratio of polyimide: hollow polyester is 15 -60: 85-40; Polyimide fiber has the characteristics of high strength, low elongation, good thermal insulation, etc. Hollow polyester fiber also has good thermal performance, using polyimide fiber, hollow polyester fiber blended yarn After being made into a fabric, it has good wear resistance and high temperature resistance, and has excellent warmth retention and comfort performance.

[0036] The warp and weft yarns of the inner layer 2 fabric are: cotton, hollow polyester blended siro compact spinning; C / T18.5tex, wherein the ratio of cotton: hollow polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com