Mold

A mold and fixed mold technology, applied in the field of molds for the production of various parts of different specifications, can solve the problems of not being able to produce products of various specifications, and achieve the effects of fewer processes, lower production costs, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

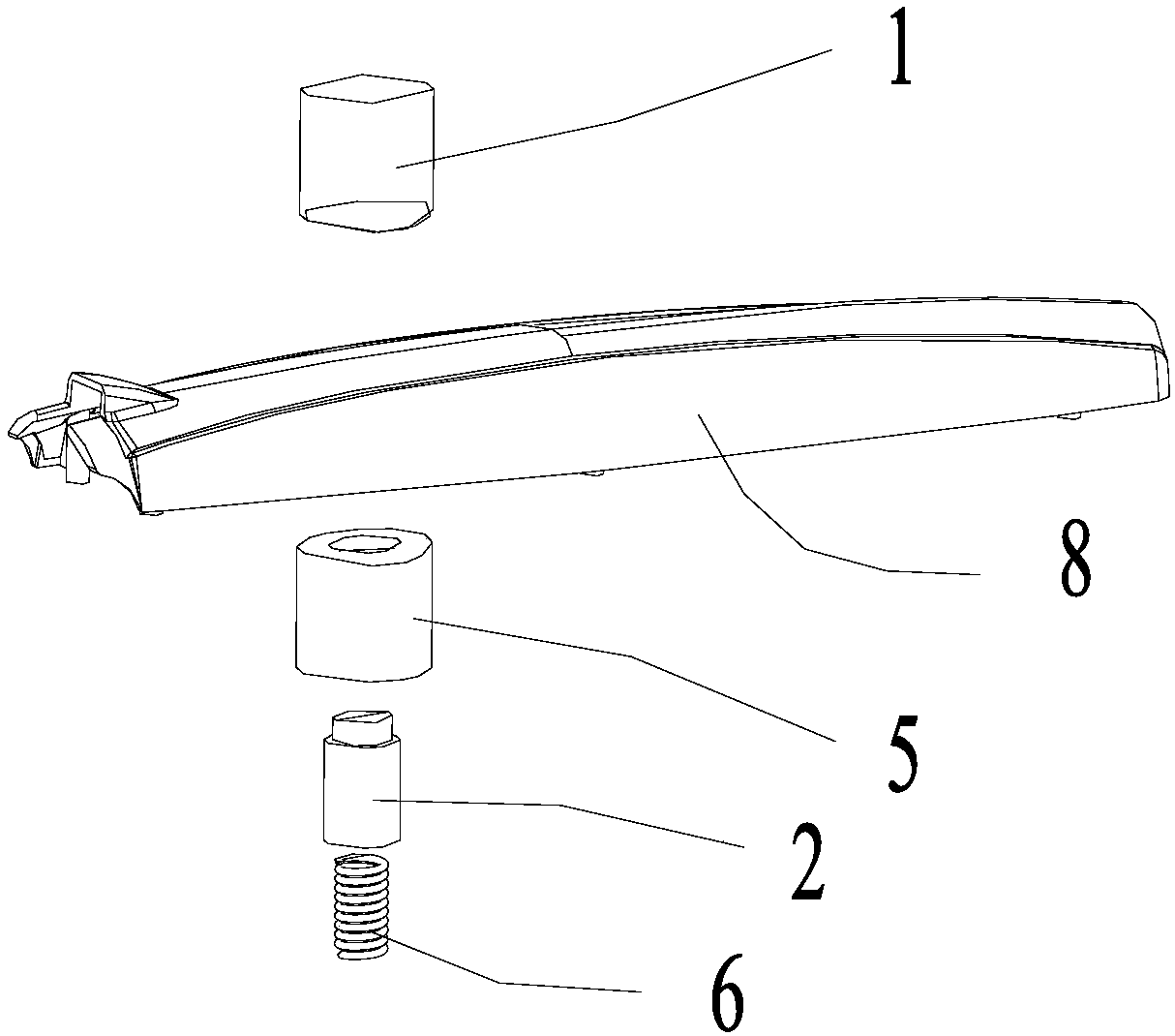

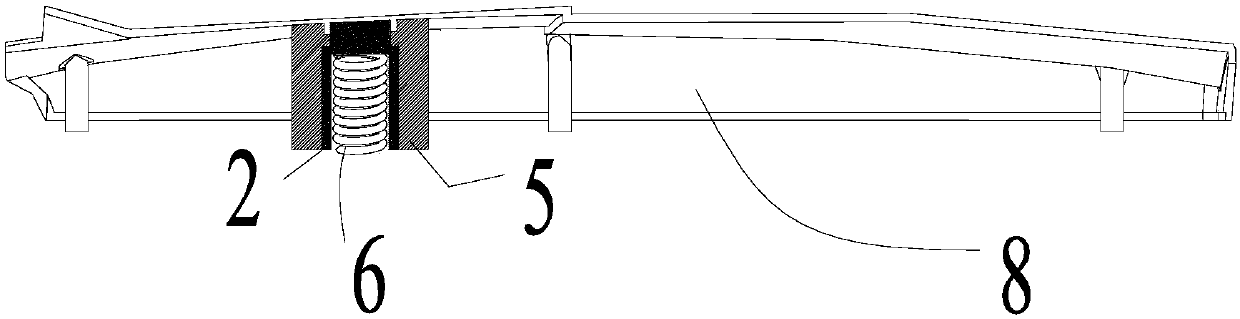

[0046] This embodiment provides a mold, such as Figures 1 to 2As shown, it includes: a fixed mold; a movable mold, a main body cavity for product 8 molding is provided between the fixed mold and the movable mold; at least one insert is installed on either the movable mold or the fixed mold piece 1, the other one is equipped with a pressing piece 2 matched with the insert, and the insert and the pressing piece 2 are detachable; in the mold closing state, the insert and the An auxiliary cavity is formed between the pressing pieces 2, and the auxiliary cavity communicates with the cavity of the main body.

[0047] In the existing technology, for products with little difference in overall structure, two sets of molds still need to be designed in the production process to produce the two products separately, which increases the difficulty of production. At the same time, for products with little demand, simultaneous development The cost of two sets of molds is higher.

[0048] I...

Embodiment 2

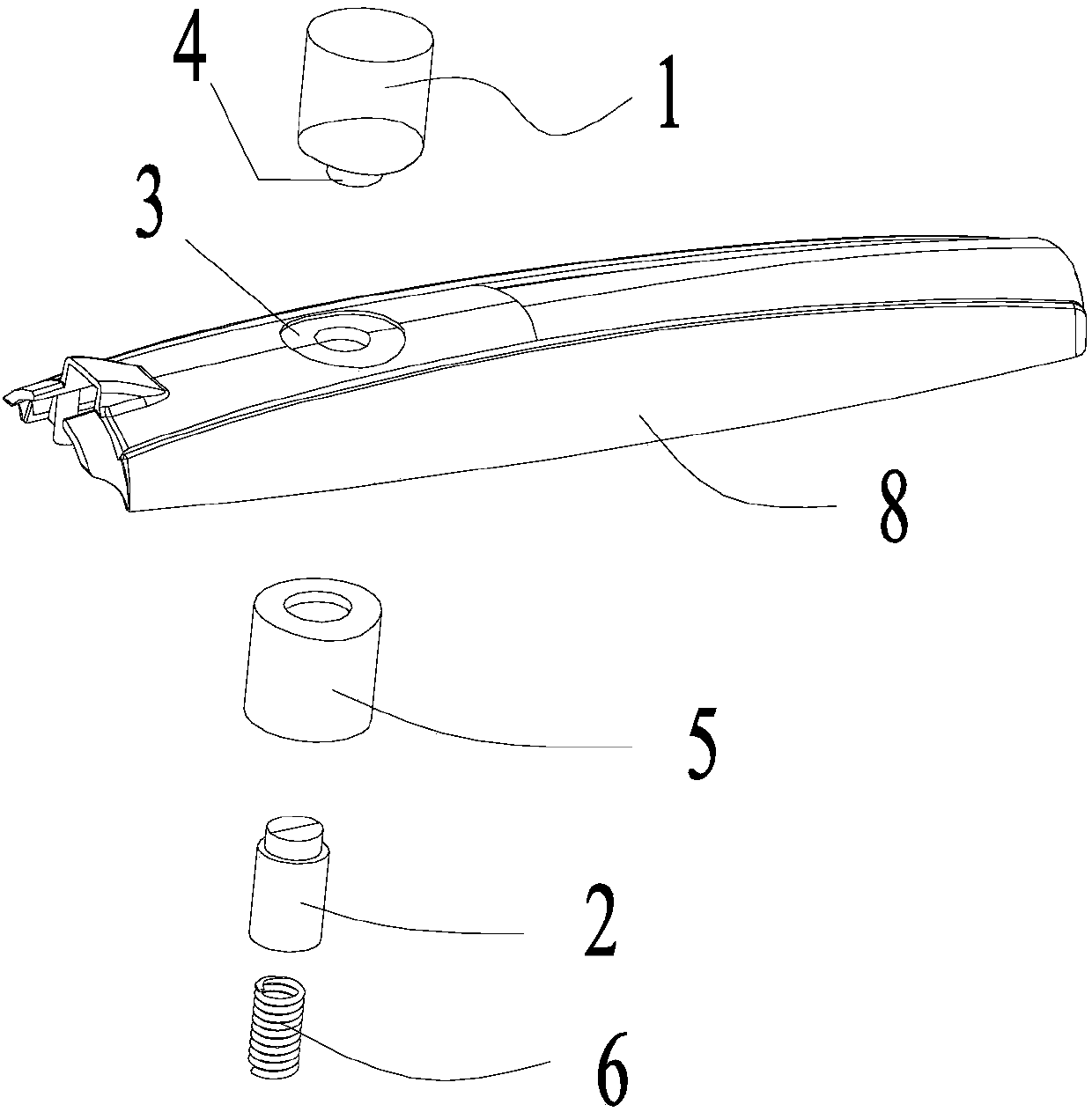

[0056] This embodiment is made on the basis of Embodiment 1. like Figure 3-5 As shown, in this embodiment, the insert 1 has a through portion 4 penetrating through the thickness of the product and abutting against the pressing piece 2 , forming a second auxiliary cavity 3 with the pressing piece 2 .

[0057] In this example, if Figure 4 As shown, the outer diameter of the through portion 4 is smaller than the outer diameter of other parts of the pressing member 2 . By setting the through part 4, the product can be better punched to form a through hole. At the same time, a step is formed at the lower end of the insert, and when the mold is closed, the insert forms a stepped counterbore on the final product.

[0058] like Figure 4 and 7 As shown, when the mold is closed, an annular chamber 9 is formed between the insert, the pressing piece 2 and the guide tube 5, and the liquid injection molding material will flow into the annular chamber 9 to form a ring. At this time, ...

Embodiment 3

[0060] This embodiment is made on the basis of Embodiment 2. In this example, if Figure 6 As shown, the part where the insert is in contact with the product is formed with reinforcing ribs. After the mold is closed, the insert forms a ring-shaped rib structure 10 on the surface of the product.

[0061] In this embodiment, the pressing member 2 is connected with a spring 6 for providing prestress toward the cavity of the main body. When the second auxiliary cavity 3 is formed between the insert and the pressing piece 2, the pressing piece 2 can be tightly attached to the insert by the spring 6, thereby ensuring the shape of the second auxiliary cavity 3 stability. Specifically, the second auxiliary cavity 3 is an annular cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com