Positioning distributed fiber anti-counterfeiting paper and manufacturing method thereof

An anti-counterfeiting paper and fiber technology, applied in non-fiber pulp addition, fiber raw material processing, paper and other directions, can solve problems such as poor anti-counterfeiting effect, and achieve the effects of various types of changes, easy identification, and difficult production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

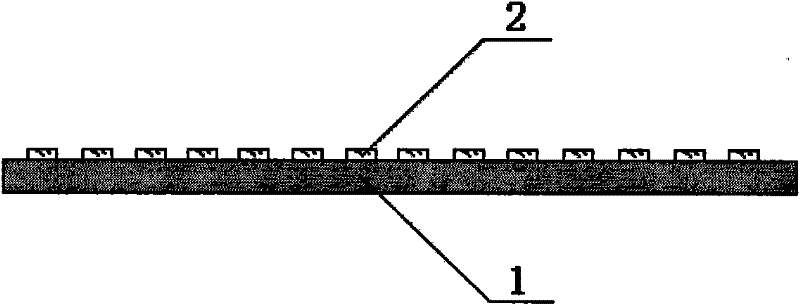

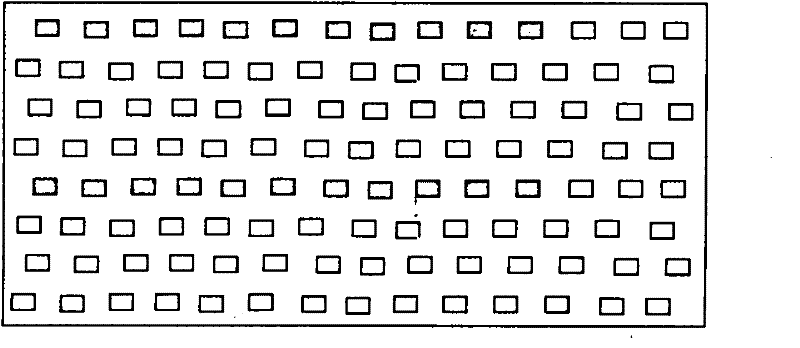

[0034] An anti-counterfeiting paper with positioning and distributed fibers, in which anti-counterfeiting fibers 2 are regularly distributed on the plane of the paper 1; the paper 1 in this embodiment contains the following raw materials in parts by weight: 900 parts of pulp, 150 parts of talcum powder, 10 parts of rosin glue, and 50 parts of aluminum sulfate 3 parts, 3 parts of cationic starch, 10 parts of oxidized starch, 0.1 part of polyacrylamide, 0.5 part of anti-counterfeiting fiber; anti-counterfeiting fiber 2 is located on one side of paper 1, and is in a raised discontinuous rectangular geometric pattern; the anti-counterfeiting fiber 2 used It is plant fiber, the color is yellow fiber, and the fiber length is 1-4mm;

[0035] A manufacturing method of the above-mentioned positioning distribution fiber anti-counterfeiting paper:

[0036] a. Make positioning distribution fiber net:

[0037] First determine the geometric pattern of the positioning distribution area and ...

Embodiment 2

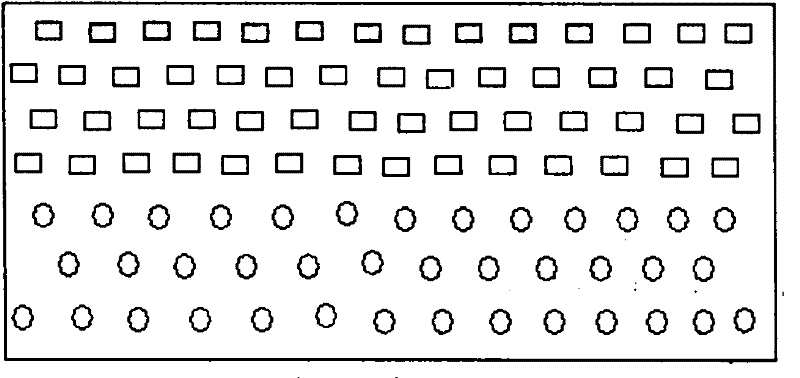

[0048] An anti-counterfeiting paper with positioning and distributed fibers, in which anti-counterfeiting fibers 2 are regularly distributed on the plane of the paper 1; the paper 1 of this embodiment contains the following raw materials in parts by weight: 800 parts of pulp, 200 parts of talcum powder, 15 parts of rosin glue, and 75 parts of aluminum sulfate , 12 parts of cationic starch, 30 parts of oxidized starch, 1 part of polyacrylamide, 1 part of anti-counterfeit fiber; anti-counterfeit fiber 2 is located on one side of paper 1, and is in the shape of raised discontinuous rectangular and circular geometric patterns; Fiber 2 is chemical fiber with two colors, red fiber and blue fiber, fiber length 3-5mm;

[0049] A manufacturing method of the above-mentioned positioning distribution fiber anti-counterfeiting paper:

[0050] a. Make positioning distribution fiber net:

[0051] First determine the geometric pattern of the positioning distribution area and its arrangement ...

Embodiment 3

[0062] An anti-counterfeiting paper with positioning and distributed fibers, in which anti-counterfeiting fibers 2 are regularly distributed on the plane of the paper 1; the following raw materials in the paper 1 of this embodiment are by weight: 950 parts of pulp, 300 parts of talcum powder, 20 parts of rosin glue, and 100 parts of aluminum sulfate , 20 parts of cationic starch, 50 parts of oxidized starch, 2 parts of polyacrylamide, 2 parts of anti-counterfeit fiber; anti-counterfeit fiber 2 is located on one side of paper 1, and is in a raised discontinuous circular geometric pattern; It is animal fiber with two colors, red fiber and blue fiber;

[0063] A manufacturing method of the above-mentioned positioning distribution fiber anti-counterfeiting paper:

[0064] a. Make positioning distribution fiber net:

[0065] First determine the geometric pattern of the positioning distribution area and its arrangement on the net, and then use paint or single-sided tape to cover th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com